Catalog excerpts

The Ensat® self-tapping threaded insert ... Ensat is a self-tapping threaded insert with external and internal thread, cutting slots or cutting bores. A continuous process of further development has brought about a number of major improvements to product characteristics. These inserts are protected by German and also foreign patents. Ensat®-S 302 (with cutting slot) is recommended for most application cases. In certain materials, this Ensat demonstrates a minimal inward springing action, so creating a certain screw locking effect. If this effect is not required, we recommend using Ensat-SB 307/308. Ensat®-SB 307/308 (with cutting bores) was developed for materials with difficult cutting properties. This insert has a thick wall and the cutting force is distributed over three cutting edges. The short version Ensat 307 is particularly suitable where minimal material thicknesses are involved. Thin-walled Ensat®-SD/SBD for applications involving special space conditions (residual wall thicknesses), and also suitable for driving using a thread tapping machine (same internal and external thread pitch). Slot version: Works Standard 303 Three-hole version: Works Standard 347/348 (see page 14). Ensat®-SBS 337/338 with three chip reservoirs. Used primarily wherever only a small amount of chips may be permitted to occur during the tapping process (see page 13). Ensat®-SBT 357/358 with closed floor for additional sealing from below. (see page 15) 4 Fields of application Product features The Ensat is used throughout the whole of the metal and plastics processing industry. • The Ensat has a large effective shearing surface (E π B), so ensuring a higher degree of pull-out strength, i.e. an Ensat M4 is often sufficient instead of a cut M5 thread (see page 5). Automotive industry, passenger and commercial vehicles Engines, transmissions, wide range of supply parts such as wing mirrors, radiators, bumpers etc. Plant and equipment construction Flange joints, construction equipment, oil burners etc. Household appliance and office machinery production Vacuum cleaners, cameras, sun lamps, drills etc. • The Ensat is driven subsequently into the finished workpiece. This means a higher casting machine output, no rejects due to incorrectly cast-in insert components, no moulding sand trapped in the thread. • A pre-cast or pre-drilled retaining hole with normal tolerance requirements is sufficient for driving in the Ensat. The thread is always precisely positioned. Electrical and laboratory supplies Capacitors, heavy current, radio and telecommunication systems, dental technology equipment. • The work steps required with wire inserts – thread tapping, breaking off trunnions etc. as well as costly wearing tools (special thread drills, limit plug gauges etc.) are not needed with the Ensat-system. Military applications Tanks, aircraft etc. • The Ensat is insensitive to small areas of shrinkage. The Ensat-system prevents damage caused by torn threads.

Open the catalog to page 1

. technologies for a reliable hold flange cover ... Connections using Ensat threaded inserts permit substantially smaller overall dimensions and thus pave the saving designs. The illustration below shows two screw connections with equal pull-out In a workpiece made of a light alloy, the Ensat 302 achieves almost maxi- mum pull-out strength with only 30 % flange cover. Pull-out strength The Ensat is capable of withstanding high loads. When used in light alloys, for example, a degree of pull-out strength is achieved which far exceeds the yield strength of the mating screw Borehole 30 % flange...

Open the catalog to page 2

The Ensat® in the workpiece ... Installation recommendation The Ensat should be processed appr. 0,1 - 0,2 mm recessed. After processing, the Ensat can be immediately subjected to load. If the component material permits subsidence of the Ensat under load, the Ensat can only execute an axial movement of 0,1 to 0,2 mm. In other words, the pretension of the screw union is largely retained, loosening of the screw connection under dynamic load is impeded. Borehole diameter [mm] Workpiece material Standard values for ENSAT 307/308 ... 337/338 Standard values for ENSAT 302 Light alloys Rm=tensile...

Open the catalog to page 3

Manual Ensat® Installation ... Manual installation Driving into steel Manual driving takes place using the driving tools 620, 621 or 610 and a tap wrench: Manual installation with driving tool and tap wrench: With Ensat®-S 302: P re-cut the thread using the drill (max. centre cutter), set the threaded stud of the tool to the full Ensat length (tool 610 cannot be adjusted). 1. Drill the hole: see page 6 for the correct diameter, countersink if necessary. 2. Screw the Ensat onto the driving tool with the cutting slot or cutting bore pointing downwards. Emergency installation using screw and...

Open the catalog to page 5

... technologies for a reliable hold Machine installation ... Machine driving process 1. P recisely position the workpiece to ensure that the hole and machine spindle are in exact alignment (do not tilt). Set the machine to the precise driving depth (appr. 0,1 – 0,2 mm below the surface of the workpiece). 2. Turn the machine to clockwise rotation. At the start of the driving process, the rotatable external shell of the tool must be resting against the external visible stop pins in such a way that it is driven by the pins in the clockwise direction. 3. Feed the Ensat towards the tool (slot...

Open the catalog to page 6All Kerb Konus catalogs and technical brochures

-

Ensat® - SI

1 Pages

-

Ensat® - SK

1 Pages

-

Ensat® - S

2 Pages

-

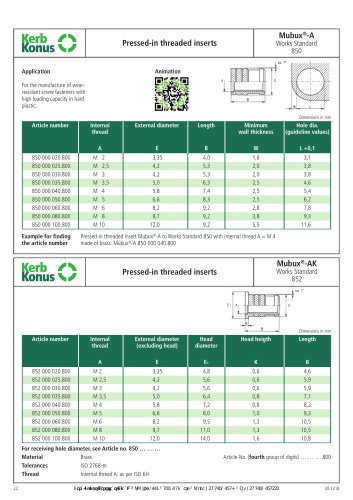

Mubux® - M without adhesive

1 Pages

-

Mubux® - MO with adhesive

1 Pages

-

Ensat® - 3F thread forming

7 Pages

-

S-Lok® - SK

1 Pages

-

S-Lok® - S

1 Pages

-

S-Lok® - RB

1 Pages

-

S-Lok® - R

1 Pages

-

S-Lok® - K

1 Pages

-

S-Lok®

1 Pages

-

Clifa® ABG

1 Pages

-

Clifa® ABO

1 Pages

-

Anchor® tank type

4 Pages

-

Anchor® mini and variants

3 Pages

-

Anchor® - rivet bushing

4 Pages

-

Threaded inserts for metal

34 Pages

-

Fasteners for thin sheet metal

30 Pages

-

Clifa® press-in nut/stud ...

4 Pages

-

Threads for thin mouldings

26 Pages

-

Threaded inserts for metals

26 Pages