Catalog excerpts

The Ensat® – self-tapping threaded insert … Ensat® is a self-tapping threaded insert with external and internal threads,cutting slots or cutting bores. A continuous process of further development has brought about a number of major improvements to product characteristics. These inserts are protected by German and also foreign patents. The Ensat® is screwed into a pre-formed or pre-drilled receiving hole and so automatically taps its own thread into the hole wall. This ensures a backlashfree fit with extreme loading capacity. Ensat®-3F 305 is a thread forming insert with 3 longitudinal grooves around its periphery Fields of application The Ensat® is used throughout the whole of the metal and plastics processing industry. – Automotive – Household appliance and office machinery production – Electrical and laboratory supplies – Plant and equipment construction – Sports and lifestyle equipment – Railed vehicles industry Product features ț Universal application for all types of plastic, thermoset plastics, thermoset plastics, PU/PUR foam, Fibre-reinforced plastic (FRP), for hardwood and plywood, hard paper and metal. ț Maximum strength values in comparison to other systems. The diagram illustrates the withdrawing force in thermoplastic materials: In thermoset plastics and FRP, the values tend to be higher. ț Thin-walled Ensat® for restricted space conditions (residual wall thicknesses), and also suitable for screwing in using a thread tapping machine (same inside and outside pitch). Slot version: WN 303, Three-hole version: WN 347/348 page 16 and 17. 3 chip reservoirs around the periphery Approx. pull-out force [kN] ➞ Ensat® Typ 302 female thread ➞ Ensat®-SBS 337/338 These cutting bores are shaped to serve as chip reservoirs. The chips created during the driving process stored here and cannot drop into sensitive equipment parts. For additional sealing from below: Ensat® with closed floor Works standard 357/358. See publication no. 20

Open the catalog to page 1

... technologies for a reliable hold The Ensat® should be processed appr. 0,1 – 0,2 mm recessed (fig. 4). After processing, the Ensat® can be immediately subjected to load. If the component material permits subsidence of the Ensat® under load, the Ensat® can only execute an axial movement of 0,1 to 0,2 mm. In other words, the pretension of the screw union is largely retained, loosening of the screw connection under dynamic load is impeded. Retaining hole The receiving hole (L, fig. 5) can be simply drilled or already provided for in the casting. Countersinking (N) the borehole (fig. 5) is...

Open the catalog to page 2

Ensat®– driving tools... On this page, you can configure the optimum tool for your application. A configuration is provided in the following as an illustrative example. The article number is composed of two sequences of numbers and starts with the tool shank (fig. 8) which should be selected in accordance with your output. Also encrypted in this number are the special versions for thin-walled Ensat® (620 1 and 621 1) and for very high driving torques (622 0 and 623 0) which are available as standard only as a square shank. Other non-standard geometries can be evaluated as standard besides...

Open the catalog to page 3

... technologies for a reliable hold Ensat®– driving tools... Example: You wish to insert an Ensat® 308 000 050. 110. For the installation process, you have selected a driving tool with spindle hexagon socket to DIN ISO 1173 and have to mount the insert into a deep positioned borehole. Shank: 636 0… (long for deep positioned borehole) Thread code: …00 050… (for thread M5) Suffix numbers: …. 000 (with always the same tools) Order no: 636 000 050.000 Tool 610 4… with magnet cores Tool 626 0… (short) 627 0… (long) Geometry similar ISO 3315 Tool 610 3… with linear bushing Tool 640 0… (short)...

Open the catalog to page 4

Measurement table In order to obtain the length dimension of the extended tool versions, the specified dimensions B must be added in each case to the dimension B1. ć = available on request Tool type 610 0..., 612 0... (manual driving tools) Tool type 610 2..., 610 3… (from M 8), 610 4… (from M6) – (for ENSAT® with hexagon socket) Tool type 626 0... (short version, square socket shank) and 627 0... (long version, square socket shank) Tool type 640 0... (short version, morse taper shaft) and 641 0... (long version, morse taper shaft) Tool type 635 0... (short version, hexagonal shaft) and 636...

Open the catalog to page 5

... technologies for a reliable hold Manual Ensat®installation … Manual Insertion Process Manual installation with driving tool and tap wrench: 10.1 The manual insertion is usually carried out using the manual tool 610 0 … via the female thread or in the case of the tools 610 2…using the hexagon socket. You can of course also use power tools for the manual assembly. If doing so, it needs to be ensured that the rotatable sleeve (2, see fig. 6) is in the corresponding correct position (see fig. 15 procedure description). Image 10.1/11.1 Thread the Ensat®, cutting geometry (slit or bore) has...

Open the catalog to page 6

Machine driving process 1. Precisely position the workpiece so that the bore and machine spindle are at right angles to each other (do not tilt). Set the machine to the precise installation depth (appr. 0.1 to 0.2 mm below the surface of the workpiece see page 5). 2. Actuate the operating lever of the machine. The rotatable outer shell of the tool must be resting against the outer visible stop pins at the beginning of the turning process so that it is driven by the pins in the clockwise direction. 3. Feed the Ensat® towards the tool (slot or cutting hole facing downwards) and grip for the...

Open the catalog to page 7All Kerb Konus catalogs and technical brochures

-

Ensat® - SI

1 Pages

-

Ensat® - SK

1 Pages

-

Ensat® - S

2 Pages

-

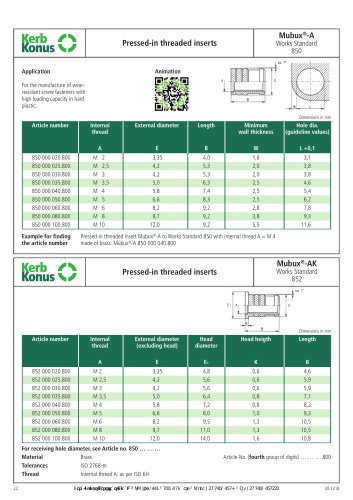

Mubux® - M without adhesive

1 Pages

-

Mubux® - MO with adhesive

1 Pages

-

S-Lok® - SK

1 Pages

-

S-Lok® - S

1 Pages

-

S-Lok® - RB

1 Pages

-

S-Lok® - R

1 Pages

-

S-Lok® - K

1 Pages

-

S-Lok®

1 Pages

-

Clifa® ABG

1 Pages

-

Clifa® ABO

1 Pages

-

Anchor® tank type

4 Pages

-

Anchor® mini and variants

3 Pages

-

Anchor® - rivet bushing

4 Pages

-

Threaded inserts for metal

34 Pages

-

Fasteners for thin sheet metal

30 Pages

-

Clifa® press-in nut/stud ...

4 Pages

-

Threads for thin mouldings

26 Pages

-

Threaded inserts for metals

26 Pages