Website:

Kent Stainless

Website:

Kent Stainless

Catalog excerpts

SUPERCLEAN HYGIENIC DRAINAGE SYSTEM SUPERCLEAN HYGIENIC DRAINAGE SYSTEM Kent Stainless is a manufacturer of Stanless Steel Drainage Channels and Gullies since 1982. Recognising the need for continuous improvement from our client base in the Brewery, Drinks, Dairy, Meat, Food and Pharmaceutical Sector, we have revolutionised the design of our industrial; channels with the addition of the Kent Superclean Hygienic Drainage Channel and Gullies. Post install changes to a drainage system is very costly and can involve replacing the entire floor – getting it right 1st time with a view to current and long term future use of the facility is worth the extra effort at the design stage. Our stainless steel drainage system is manufactured with a 30 year design life and can be expected to last a multiple of this – and indeed can outlast the building structure itself. Capacity Drains must ensure all washdown, run-off and discharge can be handled simultaneously and allow for extreme events and possible future change of use of facility. Avoid all ponding nearby which could be unhygienic, unsightly and slippery with implications for bacterial growth and H&S issues. Complete the project with Bottom Outlet and Side Outlet Gullies Kent Superclean Hygienic Drainage Channel Range Product Code Start Depth Washdown Area 1175mm / 46” minimum size, 2612mm / 103” standard size for 3.0m / 10ft crate, 5965mm / 235” suggested max size For Central Gully change to CG For MicroClean Electropolsihed change to KMHC Kent Superclean Hygienic Gully Range Product Code Body Depth Washdown Area Design Features to Consider Cleaning Drains must ensure the best possible access for cleaning thoroughly. Durability • Drains must withstand the loading of everyday traffic including small hard wheels from tray racks and bins; • withstand the loading of extreme events, • withstand hot water discharge; • withstand chemicals and disinfectants used in cleaning; • withstand run off with chemicals / acids / oil / fats / alkali used in the processing plant operations. Flooring Interface Drains must minimise at every opportunity the possibility of gaps appearing between the channel and the floor finish – which can lead to an ingress of water and become an area of growth for bacteria. Eliminate Joints Consider 6nr 3000mm runs or 3nr 6000mm runs instead of a continuous 18000mm run. 3000mm and 6000mm channel lengths can be delivered complete in 1 piece with no joints. Workmanship Choose a flooring contractor with proven experience in hygienic environments. Avoid Corners • Sharp 90 degree corners are often the 1st point of emergence of a crack which then can extend down along the length of the interface between the floor and the channel; • Round Drain Gullies minimise this and have been on the market for decades; • Rounded Channel ends are a new development from Kent Stainless which minimise this on channels; • Following Guideline 44 from the EHEDG’s Hygienic Design of Buildings Kent Stainless recommend that the utmost hygiene standard to be achieved in drainage channels is the use of rounded channel ends and rounded gullies; • In addition the grating edges on the Kent Hygiene Channel and Gully system ensure that there is no continuous flat vertical support bar on the grating edge which could ‘sandwich’ debris against the inner channel wall and prove more difficult to wash away; • This also stops debris from getting caught between normal grating side bars and channel. Water Consumption Minimise washdown water use with a tapered, presloped channel body. Hygiene At every point minimise the risk of growth of bacteria to avoid contamination. Made in IRELAND

Open the catalog to page 1

SUPERCLEAN HYGIENIC DRAINAGE SYSTEM SUPERCLEAN HYGIENIC DRAINAGE SYSTEM Kent Stainless is a manufacturer of Stanless Steel Drainage Channels and Gullies since 1982. Recognising the need for continuous improvement from our client base in the Brewery, Drinks, Dairy, Meat, Food and Pharmaceutical Sector, we have revolutionised the design of our industrial; channels with the addition of the Kent Superclean Hygienic Drainage Channel and Gullies. Post install changes to a drainage system is very costly and can involve replacing the entire floor – getting it right 1st time with a view to current...

Open the catalog to page 2

SUPERCLEAN HYGIENIC DRAINAGE SYSTEM Internal Radius of all channel folds ≥3mm: Pointed Channel Base: Base is cleaned with less water flow. Full Length Concrete Retaining Tangs: Removal of Continuous Gully Frame Shelf: Less resting water and residue = less Bacteria Presence Less places for Bacteria Traps Easier to Clean, Less Bacteria Traps For extra secure floor connection Shoulder Support Insert: Stops possible distortion under the frame under high traffic loads Open Sided Gratings: Less Edge Deformation and Floor Cracking = Less Bacteria Traps No Sharp Edges, No residue sandwiched under...

Open the catalog to page 3

SUPERCLEAN HYGIENIC DRAINAGE SYSTEM SUPERCLEAN HYGIENIC DRAINAGE SYSTEM Kent Stainless is a manufacturer of Stanless Steel Drainage Channels and Gullies since 1982. Recognising the need for continuous improvement from our client base in the Brewery, Drinks, Dairy, Meat, Food and Pharmaceutical Sector, we have revolutionised the design of our industrial; channels with the addition of the Kent Superclean Hygienic Drainage Channel and Gullies. Post install changes to a drainage system is very costly and can involve replacing the entire floor – getting it right 1st time with a view to current...

Open the catalog to page 4All Kent Stainless catalogs and technical brochures

-

IN GROUND UNITS

19 Pages

-

COMMERCIAL DRAINAGE

70 Pages

-

STREET FURNITURE

123 Pages

-

SLOT DRAINAGE

4 Pages

-

MONOLITHS

11 Pages

-

MANHOLES

128 Pages

-

PUBLIC REALM PROJECTS

132 Pages

-

Process Waste Tanks

17 Pages

-

INDUSTRIAL DRAINAGE

96 Pages

-

BOLLARDS RANGE

3 Pages

-

KENT KRE200/110 SQ

1 Pages

-

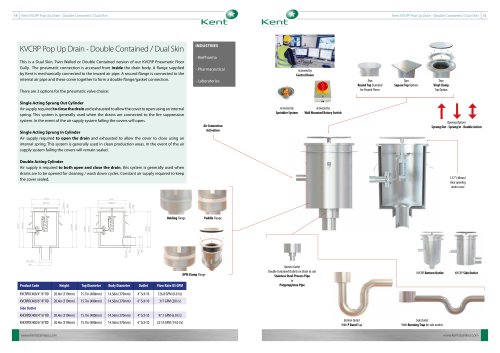

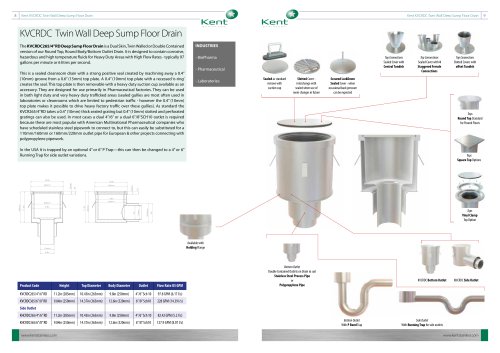

KVCR Deep Sump Floor Drain

1 Pages

-

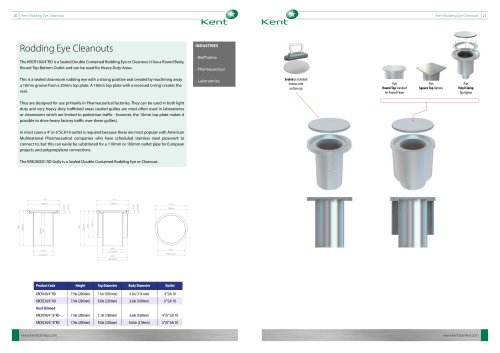

Rodding Eye Cleanouts

1 Pages

-

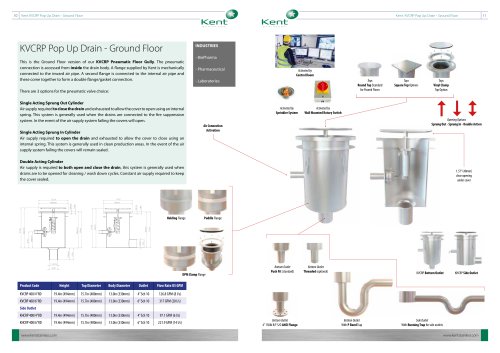

KVCR Deep Sump Floor Drain

1 Pages

-

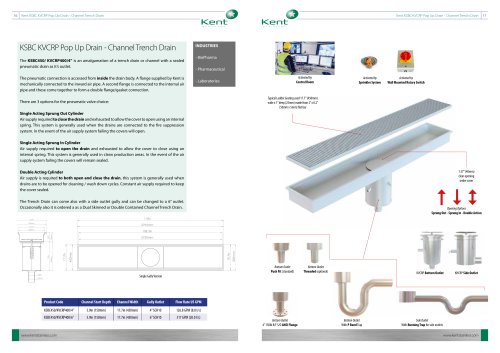

Channel Trench Drain

1 Pages