Catalog excerpts

KM_Master12_M000_M001_MINCH_SEM.qxp:Layout 1 3/6/12 8:07 AM Page M2 Beyond Solid End Mills — ™ High-performance milling in a new dimension.

Open the catalog to page 1

KM_Master12_M000_M001_MINCH_SEM.qxp:Layout 1 3/6/12 8:07 AM Page M1 Solid End Milling Tool Selection Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .M2–M5 Grades and Grade Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .M6–M7 High-Performance Solid Carbide End Mills . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .M8–M80 HARVI — Titanium, Stainless Steel, and Steel . . . . . . . . . . . . . . ....

Open the catalog to page 2

High-Performance Solid Carbide End Mills Tool Selection Guide Hard Steels Hard Steels Ball Nose

Open the catalog to page 3

High-Performance Solid Carbide End Mills Tool Selection Guide • first choice

Open the catalog to page 4

High-Performance Solid Carbide End Mills Tool Selection Guide General Application Portfolio Extension High-Performance Portfolio Extension

Open the catalog to page 5

High-Performance Solid Carbide End Mills Tool Selection Guide • first choice

Open the catalog to page 6

High-Performance Solid Carbide End Mills Grades and Grade Descriptions Coatings provide high-speed Stainless Steel Cast Iron Non-Ferrous Materials High-Temp Alloys Hardened Materials Grade Description Carbide grade made from high-quality, micrograin materials for cutting all types of workplece materials. Very high toughness ensures a controlled wear rate. The mlcrograin structure enables extremely sharp cutting edges. Coated carbide grade with thick PVD coating and optimized chemistry and process for Increased wear resistance. Outstanding protection In milling stainless steel to mitigate...

Open the catalog to page 7

Beyond Solid End Milling High-Performance milling in a new dimension Kennametal is pleased to announce KCPM15™ — the first Beyond grade for solid carbide end mills. KCPM15 features an improved high-performance carbide substrate with proprietary aluminum titanium nitride (AITÏN) PVD coating. • Engineered to increase tool life and productivity by 30%. • For use in milling steels and stainless steels. • Improved resistance to cratering, flank wear, Workpiece Materials: Grade Description Coated carbide grade with thick PVD coating and optimized chemistry and process for Increased wear...

Open the catalog to page 8

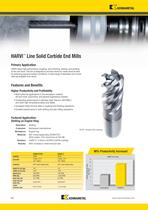

HARVI Une Solid Carbide End Mills Primary Application HARVI takes high-performance roughing, semi-finishing, slotting, and profiling to the next level. The line is designed to provide maximum metal removal rates by achieving supreme surface conditions. A wide range of diameters and corner radii are available from stock. Higher Productivity and Profitability • Best suited for applications in the aerospace, medical, die and mold, automotive, and general engineering markets. • Outstanding performance in stainless steel, titanium, INCONEL8, and other high-temperature alloys and steels. •...

Open the catalog to page 9

High-Performance Solid Carbide End Mills • HARVI™ HARVI I™ • HPHV • Unequal Flute Spacing 1 Unequal flute spacing minimizes chatter • first choice

Open the catalog to page 10

High-Performance Solid Carbide End Mills • HARVI™ HARVI I™ • HPHV • Unequal Flute Spacing NOTE: For application data, see page M26.

Open the catalog to page 14

High-Performance Solid Carbide End Mills • HARVI HARVII™ • UADE • Unequal Flute Spacing • Extended Neck 1 Unequal flute spacing minimizes chatter • first choice NOTE: For application data, see page M27. For Weldon® shank offering, please refer to www.kennametal.com/e-catalog.

Open the catalog to page 15

• Kennametal standard dimensions. • Center cutting. • Unequal flute spacing minimizes chatter High-Performance Solid Carbide End Mills • HARVI™ HARVI • HPRSHV • Unequal Flute Spacing • Long Reach • first choice NOTE: For application data, see page M27.

Open the catalog to page 16

High-Performance Solid Carbide End Mills HARVII™ • HPHVBN • Unequal Flute Spacing 1 Unequal flute spacing minimizes chatter • first choice NOTE: For application data, see page M27.

Open the catalog to page 17

High-Performance Solid Carbide End Mills • HARVI™ HARVIII™ • UCDE • Unequal Flute Spacing Kennametal standard dimensions. Non-center cutting. Unequal flute spacing minimizes chatter for smoother machining. Single tool for both roughing and finishing operations for fewer setups Five-flute geometry enables slotting up to 1 x D. • first choice

Open the catalog to page 18

High-Performance Solid Carbide End Mills • HARVI HARVI II™ • UCDE • Unequal Flute Spacing NOTE: For application data, see page M28. %_{ Help preserve and protect our planet! It's easy for your company to be environmentally conscious with the Kennametal Carbide Recycling Program. By sending us your used carbide tools, you help preserve and protect the environment and ensure that these products are recycled responsibly. Kennametal accepts any coated or non-coated carbide items, including inserts, drills, reamers, and taps. By using the Kennametal Carbide Recycling Program, you will receive: •...

Open the catalog to page 19

High-Performance Solid Carbide End Mills • HARVI™ HARVI II™ • UCDE • Unequal Flute Spacing • Extended Neck 1 Unequal flute spacing minimizes chatter 1 Single tool for both roughing and finishing operations for fewer setups. 1 Five-flute geometry enables slotting up to 1 x D. • first choice NOTE: For application data, see page M28.

Open the catalog to page 20

High-Performance Solid Carbide End Mills • HARVI HARVI II™ • UGDE • 3 x D and 5 x D Lengths of Cut • Kennametal standard dimensions. • Non-center cutting. • Unequal flute spacing minimizes chatter • For finishing and semi-finishing applications. • first choice

Open the catalog to page 21

High-Performance Solid Carbide End Mills • HARVI™ HARVIII™ • UGDE • 3 x D and 5 x D Lengths of Cut NOTE: For application data, see page M29.

Open the catalog to page 22

High-Performance Solid Carbide End Mills • HARVI HARVII™ • HPHVT • Unequal Flute Spacing NOTE: For application data, see page M29.

Open the catalog to page 23All Kennametal catalogs and technical brochures

-

CB11 Stack-On

2 Pages

-

Grinder Tips

16 Pages

-

Grader Blades

40 Pages

-

Road Rehabilitation • Road King

24 Pages

-

Underground Mining

182 Pages

-

ROCTEC ecoline

1 Pages

-

Conforma Clad X2™

2 Pages

-

INNOVATIONS 2020

84 Pages

-

INNOVATIONS 2019

156 Pages

-

Tooling Systems News 2018

60 Pages

-

Oilfield Radial Bearings

2 Pages

-

Cladding Formulas Oilfield

2 Pages

-

General Conveyance Equipment

4 Pages

-

Twin-Screw

2 Pages

-

EDM Blocks Brochure

8 Pages

-

KMT_Wear Solutions_Brochure

12 Pages

-

Alloys Brochure Direct

28 Pages

-

Kennametal Stellite Alloys

15 Pages

-

Composite Rods

1 Pages

-

Fluidized Bed Boiler Tubes

1 Pages

-

Mill Roll Brochure

8 Pages

-

Snowplow Blades

1 Pages

-

KenCast Wear Protection

20 Pages

-

7690VA09

3 Pages

-

Tool Selection

3 Pages

-

Indexable Milling Index

8 Pages

-

Milling geometries quick

9 Pages

-

Milling grades

4 Pages

-

Specialty Carbide Catalog

16 Pages

-

Tooling Systems 2013 Catalog Sections

1576 Pages

-

INNOVATIONS CATALOGUE 2015

260 Pages

-

Kennametal Innovations 2014

630 Pages

-

KMT KBH20 metric

18 Pages

-

Master Catalog 2013 Complete - metric

2122 Pages

-

Railroad Brochure

24 Pages

-

Abrasive Blast Nozzles Catalog

60 Pages

-

Surface Mining Catalog

42 Pages

-

Holemaking Taps (metric)

118 Pages

-

Threading

108 Pages

-

O.D. / I.D. Toolholders

162 Pages

-

PCD / PCBN Inserts

66 Pages

-

ISO / ANSI Inserts

132 Pages

-

Thread Mills

20 Pages

-

Copy Mills

118 Pages

-

Slotting Cutters

56 Pages

-

Shoulder Mills

96 Pages

-

Face Mills

138 Pages

-

Taps

194 Pages

-

Hole Finishing

214 Pages

-

Indexable Drills

108 Pages

-

Combination Tools

28 Pages

-

Modular Drills

62 Pages

-

Solid Carbide Drills

112 Pages