Website:

Keller Lufttechnik GmbH + Co. KG

Website:

Keller Lufttechnik GmbH + Co. KG

Catalog excerpts

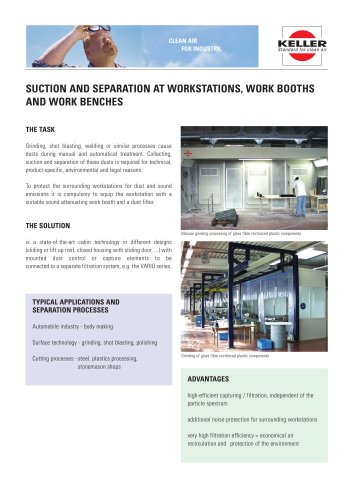

Grinding, shot blasting, welding or similar processes causedusts during manual and automatical treatment. Collecting, suction and separation of these dusts is required for technical, product-specific, environmental and legal reasons.To protect the surrounding workstations for dust and soundemissions it is compulsory to equip the workstation with a suitable sound attenuating work booth and a dust filter. > Manual grinding processing of glass fibre reinforced plastic components is a state-of-the-art cabin technology in different designs (sliding or lift up roof, closed housing with sliding door, ...) with mounted dust control or capture elements to be connected to a separate filtration system, e.g. the VARIO series. > Automobile industry - body makingSurface technology - grinding, shot blasting, polishing Cutting processes -steel, plastics processing, stonemason shops > Grinding of glass fibre reinforced plastic components high-efficient capturing / filtration, independent of the particle spectrumadditional noise protection for surrounding workstationsvery high filtration efficiency = economical air recirculation and protection of the environment >

Open the catalog to page 1

900 450 570 515 > 3250 1260 with door 13501050 Work booth EZV 2 3000 - 3500 mس/h 4000 - 4500 m/h 5500 - 6000 mӳ/h 2.1 2.2 2.3 filter elements type 1200/18 1200/18 1200/18 number pcs 8 10 12 surfacem 30 38 46 motor > 1) outputkW 5,5 7,5 11,0 valves > 2) numberpcs 4 5 6 compressed air > 3) consumptionL/min 30 30 30 sound level > 4) dB(A) 75 75 75 blow out noise > 5) dB(A) 82 82 85 weight basic unitkg 1070 1100 1140 > 1) voltage 400 V / 50 Hz, speed 3000 min-1 > 2) nominal width 2 inches, voltage 24 V DC > 3) nominal pressure 6 bar, consumption in litre under normal conditions if the pulse...

Open the catalog to page 3

Flow analysisinlet cross section of the work booth 0.6 m/s 0.2 acb Work booths width a any selectable heightb any selectable depthc any selectable number of separation cells depends on work booth dimensions number of exhaust cells depends on work booth dimensions 4 >

Open the catalog to page 4

1200 40 Universal applicable:- sound insulation - welding screen - spark protection - grinding protection - room divider - robust sheet steel construction - adjustable height by square profilethreaded shaft- hand lever operated table lock - wooden slatsTechnical data:load capacity up to 1500 kg table height from 600 to 900 mm adjustable paint finishRAL 7032 > 1920 100 > 1350 For vacuuming up coarse particles such as metal swarf from milling, turning and drilling operation thatordinary extraction systems do not handle. Therefore, we offer a simple but very effective suction unit with 134 6 >...

Open the catalog to page 6

Extraction cell AZ is a component of our work booth CABIN-STANDARD and is also combined with CABIN-individual or other workstation enclosures that may be connected to special filter units or centralised exhaust systems.The extraction cell consists of a welded sheet steel housingwith three resp. four extraction slots, fitted with an impact plate in the front and outlet spigot for ductwork connection.Paint finish:RAL 7032 pebble grey, except galvanized parts.Weight: 140 kg > 2480 Titanium grinding 7 >

Open the catalog to page 7

concrete polymer grinding (machine basic body) manual grinding workstations Keller Lufttechnik - all rights reserved. Subject to modifications. 07/2008 www.loerz-company.de Airbus, Bremen Epucret, Rechberghausen Casper, Nɶttingen Knig, Hochdorf Krauss-Maffai Wegmann, Kassel Rotorblattfertigung, Magdeburg Sulzer Infra, Ravensburg > Dipl.-Ing. (FH) Thomas Schneider Keller Lufttechnik GmbH + Co. KG Neue Weilheimer Strae 30 73230 Kirchheim unter Teck, GERMANYPhone +49 7021 574 - 191Fax +49 7021 574 - 135 E-Mail st Keller Lufttechnik GmbH + Co. KG Neue Weilheimer Stra柟e 30 73230 Kirchheim unter...

Open the catalog to page 8All Keller Lufttechnik GmbH + Co. KG catalogs and technical brochures

-

AmbiTower

4 Pages

-

JET-SET

4 Pages

-

PT-Filter

4 Pages

-

VARIO eco

8 Pages

-

Exhaust hoods/nozzle plates

2 Pages

-

Volume flow regulator ProFix

4 Pages

-

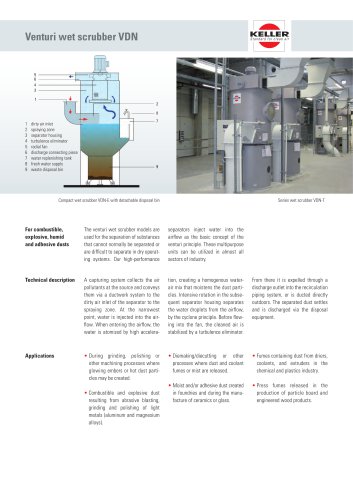

Wet scrubber VDN

12 Pages

-

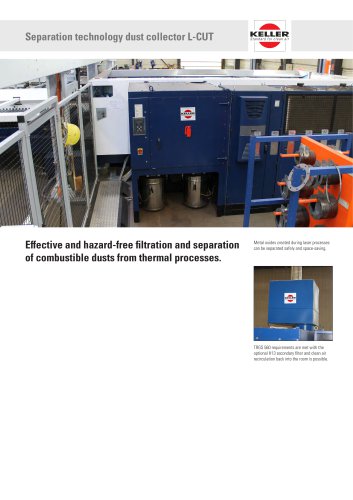

Dry separator L-CUT

4 Pages

-

Dry separator VARIO 2014

12 Pages

-

Coolant mist separator ENA-D

8 Pages

-

JET-SET

8 Pages

-

Movable extractor arms

2 Pages