Website:

Keller Lufttechnik GmbH + Co. KG

Website:

Keller Lufttechnik GmbH + Co. KG

Catalog excerpts

VARIO – Separation of fine dust particles The VARIO series is particularly suitable for separation of fine dust. The VARIO units are of modular construction in order to meet different requirements, such as dust characteristics or the volume of exhausted air.

Open the catalog to page 1

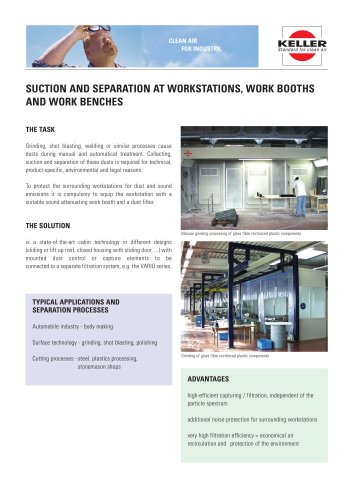

Separation of fine dust Keller Lufttechnik plans, engineers and fabricates systems to keep air clean in all industrial sectors in which air pollutants are collected, transported and separated. Innovative filter technologies and a systematic equipment design ensure optimal separation results. The VARIO series is particularly suitable for separation of fine dust. Nearly all types of dust can be successfully separated, such as those created in metal processing, polymer processing, and in chemical, pharmaceutical and ceramic industries, as well as non-metallic minerals. Mechanical and thermal...

Open the catalog to page 2

The dust-laden air flows through the dirty air inlet into the filter unit. A baffle plate slows down and deflects the dust particles to protect the filter elements from direct impact. An air down-flow is created between the filter elements, allowing the dust par- ticles to drop. A fan in the clean air chamber draws the polluted air through the filter elements, depositing the dust particles onto the filter surface. Because the filter elements are cleaned continuously by compressed air pulses during operation, Filter elements The filter elements are of high quality and are available in a...

Open the catalog to page 3

Waste disposal and safety Waste disposal Standard: The air-tight and dust-tight For larger dust volumes or in 24-hour disposal bins are connected to the operations, the waste disposal is filter's hopper with a clamping device, continuous via rotary valves, into simplifying the exchange of dust col- disposal tanks or Big Bags. Further lector containers. alternatives are available - gate valve (optional) - rotary lock Safety It is possible to equip the VARIO units with security technology if combustible or explosive dusts are created during Explosion suppression by automatic entry of ProFlap...

Open the catalog to page 4

The direct-drive radial fan is very silent. Depending on the size of the filter unit, the fan is either integrated, topmounted or placed next to it. Installation outdoors is possible if weather protection is provided and is within noise limit requirements. Venting outdoors of re-circulation Air recirculation is often possible with the use of high-quality SINBRAN filter elements. The cleaned air can be ducted and channeled (even with heat exchangers) to the outdoors, or re-circulated back into the workplace. Alternate venting or recirculation can be accomplished by activating a switch within...

Open the catalog to page 5

Technical data VARIO 1 Basic unit Unit type Filter elements SINBRAN Cartridge 5) Valves Compressed air 1) Motor 2) Sound pressure level 3) Basic unit Variation H 4 - 6 bar pressure according to filter elements; standard cleaning interval 3 min; volume of the compressed air tank 10,5 L Voltage 400 Volt/50 Hz, Speed 3000 min-1 1 m in front of the door; measurement method according to DIN EN ISO 3744, with connected suction pipe. 1 m distance from the blow out 45 °, measurement method according to DIN EN ISO 3744 different materialqualities

Open the catalog to page 6

Technical data VARIO 2 Basic unit Unit type Filter elements SINBRAN Cartridge 5) Valves Compressed air 1) Motor 2) Sound pressure level 3) Basic unit Compressed air 4 - 6 bar je nach Filterelement; Abreinigungsintervall Standard 3 min; Volumen Compressed airtank 15 l. Spannung 400 Volt/50 Hz, Drehzahl 3000 min-1 3) 1 Meter vor der Tür; Messverfahren nach DIN EN ISO 3744, mit angeschlossener Saugrohrleitung. 4) 1 Meter vom Ausblas entfernt unter 45°; Messverfahren nach DIN EN ISO 3744. 5) verschiedene Materialqualitäten 1)

Open the catalog to page 7

Technical data VARIO 3 Basic unit Unit type Cartridge 5) Valves Compressed air 1) Motor 2) Sound pressure level 3) Basic unit Different from Vario 3 Standard, the filter system is 200 mm lower (H = 3660 mm)! 4 - 6 bar pressure according to filter elements; standard cleaning interval 3 min; volume of the compressed air tank 17,5 L 2) Voltage 400 Volt/50 Hz, Speed 3000 min-1 3) 1 m in front of the door; measurement method according to DIN EN ISO 3744, with connected suction pipe. 4) 1 m distance from the blow out 45 °, measurement method according to DIN EN ISO 3744 5) different...

Open the catalog to page 8

Technical data VARIO 4 Unit type Filter elements Valves 1) Compressed air 2) Motor 3) Sound pressure level 4) Basic unit Variation A In derogation from VARIO 4, crude gas only possible from one side! 2 or 1 valve(s) is/are not connected at VARIO 4.1 and 4.2 6 bar pressure; standard cleaning interval 1 min; volume of the compressed air tank 21,5 L. Voltage 400 Volt/50 Hz, Speed 3000 min-1 1 m in front of the door; measurement method according to DIN EN ISO 3744, with connected suction pipe. 1 m distance from the blow out 45 °, measurement method according to DIN EN ISO 3744

Open the catalog to page 9

Technical data VARIO 5 Unit type Filter elements Valves 1) Compressed air 2) Motor 3) Sound pressure level 4) ) 2 valves are not connected at VARIO 5.1. 6 bar pressure; standard cleaning interval 1 min; volume of the compressed air tank 30,5 L. 3) Voltage 400 Volt/50 Hz, Speed 3000 min-1 4) 1 m in front of the door; measurement method according to DIN EN ISO 3744, with connected suction pipe. 5) 1 m distance from the blow out 45 °, measurement method according to DIN EN ISO 3744 1

Open the catalog to page 10

Technical data VARIO 6 Basic unit Unit type Filter elements Valves 1) Compressed air 2) Motor 3) Sound pressure level 4) 4 or 2 valves are not connected at VARIO 6.1 and 6.2 6 bar pressure; standard cleaning interval 1 min; volume of the compressed air tank 21,5 L. 3) Voltage 400 Volt/50 Hz, Speed 3000 min-1 4) 1 m in front of the door; measurement method according to DIN EN ISO 3744, with connected suction pipe. 5) 1 m distance from the blow out 45 °, measurement method according to DIN EN ISO 3744 1)

Open the catalog to page 11

VARIO 2 for chip extraction VARIO 5 with spark preseparator and heat recovery system VARIO 3 for grinding cabin extraction © Keller Lufttechnik - all rights reserved. Subject to modifications. VARIO 1 for high pressure unit

Open the catalog to page 12All Keller Lufttechnik GmbH + Co. KG catalogs and technical brochures

-

AmbiTower

4 Pages

-

JET-SET

4 Pages

-

PT-Filter

4 Pages

-

VARIO eco

8 Pages

-

Exhaust hoods/nozzle plates

2 Pages

-

Volume flow regulator ProFix

4 Pages

-

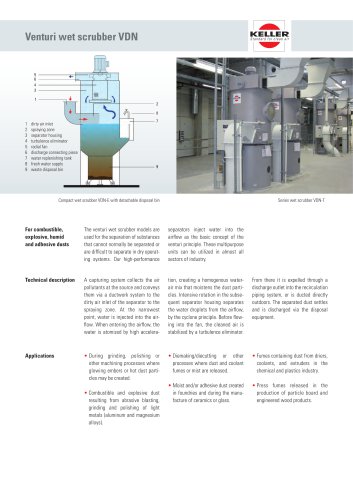

Wet scrubber VDN

12 Pages

-

Dry separator L-CUT

4 Pages

-

Coolant mist separator ENA-D

8 Pages

-

JET-SET

8 Pages

-

Movable extractor arms

2 Pages