Catalog excerpts

Explosive dusts from dry processes or MQL extracted directly at the machine The innovative design system TR-1 ProVent Plus ensures that single sepa- rators with flameless pressure relief can be installed without a designated protective zone - even for processes with light metal dusts! The new shock pressure resistant pro- tection shaft absorbs the shock wave

Open the catalog to page 1

Dust emissions separated directly at the machine Advantages of single separation TR-1 for MQL and dry processing was designed as a stand-alone-system to be installed adjacent to a machine (emission source). Installation close to the machine is flexible. Due to its compact design, little space is required. In contrast to current central separation systems this unit is very flexible and ensures a high return on investment. Transfer to another machine is easy. New and faster processes, as well as new materials require adaptability when handling explosive dusts. Standalone separators are...

Open the catalog to page 2

Highly efficient separation means omitting the venting of exhaust air to the outdoors. The clean air exits the system on top and is redirected into workplace in an energy efficient the manner. A clean air duct and more efficient fan can be excluded because of the direct clean air discharge. Single separator TR-1 ProVent Plus attached to a machining center Dust collection with ProChip Separation of dust emissions by the ProChip collection device Dirty air collection with ProChip Because of the flow lock, collected chips bounce off and fall back into the workplace. The resulting centrifugal...

Open the catalog to page 3

Heavy-duty filtration Dust extraction with maximum separation efficiency The dust particles accumulate on the surface of the cartridge filters. Tiniest aerosol residues are separated by a storage filter (category H13) in the secondary filter stage. As a result, a separation efficiency of 95.95 % is achieved for suspended matter of 0.1 µm to 0.3 µm. Noise absorbent coating Pressurized dispenser for air flow monitoring Radial fan Temperature sensor to monitor possible smoldering fires The filter cartridges in the main filter stage Secondary filter stage H13 (storage filter) Cleaning unit with...

Open the catalog to page 4

How dust explosions are created Explosive conditions During every compressed air pulse cleaning of the filter cartridges, an explosive atmosphere is created which only exists for a few seconds. Pulse cleaning, disperses dust. If all other elements (as described below) are present in sufficient quantity, there basically exists the risk of explosion. Combustible dust This risk is limited by the lower and upper explosion limit of the explosion atmosphere. A mere mixture of generally < 60 g/m3, falls below the lower explosion limit (LEL). The upper explosion limit (UEL) is exceeded at a...

Open the catalog to page 5

TR-1 explosion protection series Explosive dusts can be controlled As an add-on to the basic design, the TR-1 series offers various configurations for applications involving explosive dusts. magnesium and modern metal compounds can be extracted and separated safely with corresponding safety measures. In addition to non-combustible dusts, the explosive dusts from the treatment of light metals such as aluminum, Even inorganic dusts from processing plastics can become explosive. TR-1 series with various protective devices The “customization” of modular components fulfills specific requirements...

Open the catalog to page 6

Avoidance of dust explosions TR-1 AS For ignition source free operation The antistatic design TR-1 AS is ideally suited for the processing of inorganic materials such as plastic or when ignition sources are present. During filter cartridge cleaning, an explosive atmosphere is present, however it has no impact since there is no ignition source. All components are grounded to avoid the creation of antistatic charges. Combustible dust Brennbarer Staub (plastics, light (Kunststoffe, Leichtmetals ...) Ignition source Zündquelle Dispersed dust (during cleaning) Housing Verdämmung (filter housing)...

Open the catalog to page 7

Safe metal dust explosions Cleaning of the filter cartridges is performed when the system is shut off for which the antistatic design of the TR-1 AS is ideally suitable (offline cleaning) at the TR-1 ProSens. With ignition source monitoring by ProSens In fact, although there exists an ignition source inside the separator, an explosive environment cannot be prevented by shutting down the cleaning process. Since sparks can be created during the processing of light metals, especially of aluminum, the extraction system is monitored by a spark sensor. The machine and filter system shut down at...

Open the catalog to page 8

Neutralization of dust explosions TR-1 ProVent Plus With shock pressure resistant protection shaft The further development of constructive explosion protection offers Keller the possibility to separate explosive metal dusts from dry applicatons or MQL directly at the corresponding machine without any hazard and to clean the filter cartridges at the same time without interrupting the process. This ensures a highly efficient shift operation for MQL processes. TR-1 ProVent Plus Constructive explosion protection Explosion pressure is derieved without any hazard (explosion pressure relief)...

Open the catalog to page 9

No hazard for metal dust explosions TR-1 ProVent Plus No safety zone required TR-1 ProVent Plus single separator no longer requires a safety zone due to its new shock pressure resistant shaft. The shock wave and hot gases are largely absorbed and vented upwards. Back pressure flap ProFlap A metal dust explosion is no longer a hazard for the operator and the environment. A testing for the flameless pressure relief of metals according to EN 16009 was performed sucessfully according to EN 16009. Single separator TR-1 ProVent Plus With new, pressureresistant protective shaft for hazard-free...

Open the catalog to page 10

Comprehensive system solutions available TR-1 for MQL and dry processing is part of the newly designed, energy-efficient, and flow-optimized separation solution to keep air clean during metal treatment processes. Consulting service Do not hesitate to contact us for detailed information on the TR-1’s application possibilities in the treatment of metal and plastics. We are pleased to offer you a consultation without obligation as a dialog partner in the assessment phase of your project. We will be pleased to present you with detailed information on our technologies and solutions. To assist in...

Open the catalog to page 11All Keller Lufttechnik GmbH + Co. KG catalogs and technical brochures

-

AmbiTower

4 Pages

-

JET-SET

4 Pages

-

PT-Filter

4 Pages

-

VARIO eco

8 Pages

-

Exhaust hoods/nozzle plates

2 Pages

-

Volume flow regulator ProFix

4 Pages

-

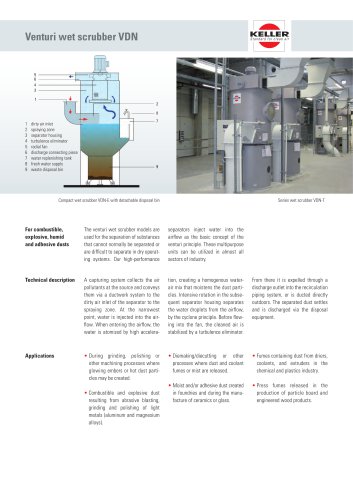

Wet scrubber VDN

12 Pages

-

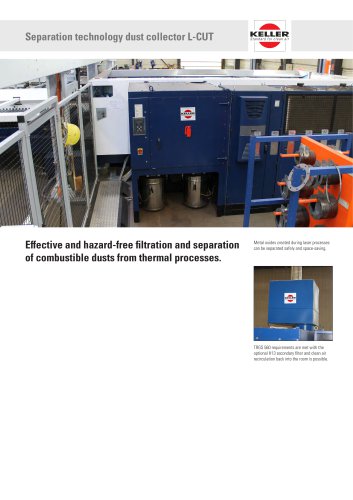

Dry separator L-CUT

4 Pages

-

Dry separator VARIO 2014

12 Pages

-

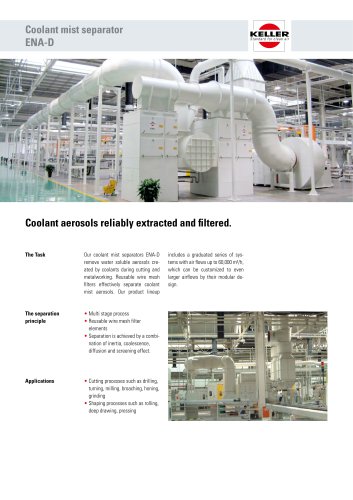

Coolant mist separator ENA-D

8 Pages

-

JET-SET

8 Pages

-

Movable extractor arms

2 Pages