Catalog excerpts

PT FILTER UNITS - SEPARATION OF FINE DUST PARTICLES TASK Keller plans, engineers and fabricates systems to maintain air quality in all industrial applications in which air pollutants are collected, transported and separated. Innovative filter technologies and a systematic equipment design ensure optimal separation results. The PT Filter series is particularly suitable for separation of fine dust. Nearly all types of dust can be successfully separated, such as those created in metal processing, polymer processing, and in chemical, pharmaceutical and ceramic industries, as well as non-metallic minerals. PT Filter units are modular in design order to meet different requirements, such as dust characteristics or the volume of exhausted air. Sturdy and low-noise units allow for reliable 24-hour operation with constant air flow. EXAMPLES OF APPLICATIONS Mechanical and thermal processes during which dry, airborne dust is created. Grinding Drilling, Turning Thermal Joining Thermal Cutting Blending, Weighing Thermal Spraying Filter elements for a variety of material properties Modular design Disassembles into identical components Flexible installation options Simplified installation in hard-to-access area Access on the clean air side to the horizontally installed filter elements - Vertically designed upward pressure relief is possible - Suitable for explosion protection measures for indoor and outdoor installations

Open the catalog to page 1

FILTER ELEMENTS The PT series operates according to the downflow principle. The dust laden air enters via the air inlet into the upper section of the filter housing and flows around the filter elements from top down. The polluted air is sucked through the filter elements that are fixed to the slotted wall and the dust collects on the surface of the filter elements. Cleaning of the filter elements is achieved by means of compressed air pulses during filtration operation. Thus, the air volume of the fan remains nearly constant. The clean gas (cleaned air) exits through the top of the unit and...

Open the catalog to page 2

Technical data PT FILTER Type-114 2310 single storied Filter elements SINBRAN Multitube Y-Filter Tank Double tank double storied Unit types amount filtration surface filter type filtration surface filter type filtration surface filter type amount Valves amount Valves Only one valve is controlled, nominal pressure 6 bar Cleaning interval Standard PT-114/228 1,5 min Cleaning interval Standard PT-121/242 1 min pcs. m² SINBRAN® m² Multitube m² Y-Filter Stück Stück Stück Stück NL/Impulse1) kg

Open the catalog to page 3

The direct-drive radial fan is very silent. Depending on the size of the filter unit, the fan is either integrated, top-mounted or placed next to it. It is possible to equip PT Filter systems with security technology if combustible or explosive dusts are created during the manufacturing process. VENTING OUTDOORS OR RE-CIRCULATION Air recirculation is often possible with the use of high-quality filter elements. The cleaned air can be ducted and channeled (even with heat exchangers) to the outdoors, or re-circulated back into the workplace. Alternate venting or recirculation can be...

Open the catalog to page 4All Keller Lufttechnik GmbH + Co. KG catalogs and technical brochures

-

AmbiTower

4 Pages

-

JET-SET

4 Pages

-

PT-Filter

4 Pages

-

VARIO eco

8 Pages

-

Exhaust hoods/nozzle plates

2 Pages

-

Volume flow regulator ProFix

4 Pages

-

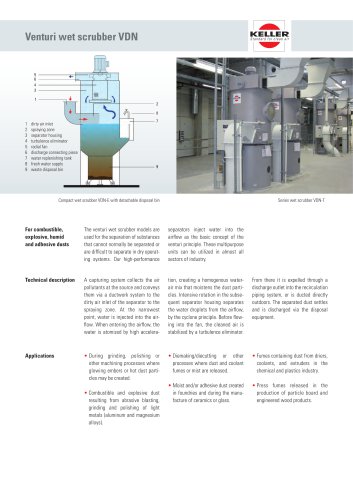

Wet scrubber VDN

12 Pages

-

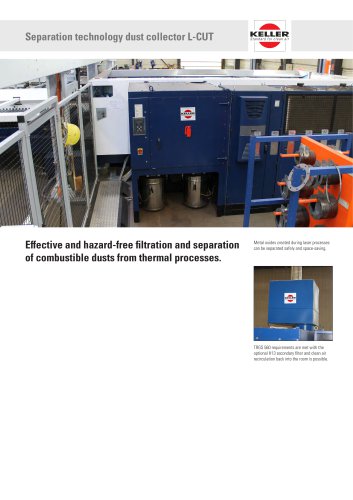

Dry separator L-CUT

4 Pages

-

Dry separator VARIO 2014

12 Pages

-

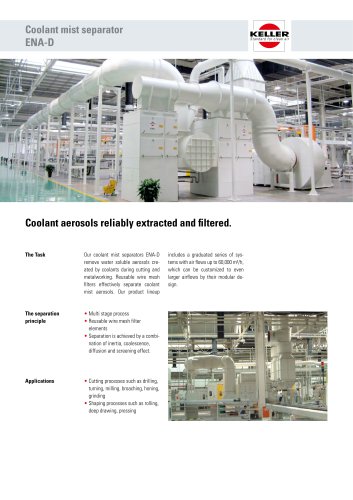

Coolant mist separator ENA-D

8 Pages

-

JET-SET

8 Pages

-

Movable extractor arms

2 Pages