Catalog excerpts

Keller Lufttechnik plans, engineers, and manufactures air pollution control systems for the capture, separation and removal of airborne particles for all types of industry. High filtration efficiency is achieved with innovative filtration technology and efficient design. Suitable exhaust systems offer solutions to individual applications while maintaining high quality standards. The JET-SET series is especially suitable for the separation of high-volume fine dust particles. Nearly all types of dust can be successfully separated, such as those created in meta processing, polymer processing, recycling industry, timber ndustry as well as non-metallic minerals. The JET-SET units are modular in design in order to meet different requirements, such as dust characteristics, dust accumulation or the volume of exhausted air. The quiet units maintain a constant air flow, allowing for a trouble-free 24-hour operation. Short delivery times and competitive pricing are achieved through series production planning.

Open the catalog to page 1

The dust-laden air (dirty air) flows through the inlet opening (1 ) into the filter unit. A baffle plate (2) slows down and deflects the coarser dust particles to avoid direct impact on the filter. The dirty air is directed onto the filter plenum (11) and circulates from the top down around the filter elements (3), causing the settling of fine dust particles. The dust-laden air flows through the filter bags to the inside while the dust particles remain on the filter surface. The separated air (clean gas) flows from the separator through the clean gas outlet (9) and is either re-circulated...

Open the catalog to page 2

The air-tight and dust-tight disposal bins are connected to the filter hopper with a clamping device, simplifying the exchange of dust collector bins. For larger dust quantities or during 24-hour operation, continuous disposal is accomplished by means of a rotary lock in the waste disposal bin or by the use The JET-SET filter can be equipped with additional safety devices when processing combustible or explosive dusts. Regulations such as the ATEX, VDI 2263, VDI 3673 etc. are always taken into consideration. - rotary lock - gate valve Depending on the exhaust air quality, the cleaned air...

Open the catalog to page 3

© Keller Lufttechnik - all rights reserved. Subject to modifications. 04/2010 www.loerz-company.de CLEAN AIR FOR INDUSTRY. CONTACT Dipl.-Ing. (FH) Peter Wörner Keller Lufttechnik GmbH + Co. KG Neue Weilheimer Straße 30 73230 Kirchheim unter Teck, GERMANY Telefon +49 7021 574-274 Telefax +49 7021 574-145 E-Mail: wp@kl-direkt.de Keller Lufttechnik GmbH + Co. KG Neue Weilheimer Straße 30 73230 Kirchheim unter Teck, GERMANY Phone +49 7021 574-0 · Fax 52430 www.kl-direkt.de

Open the catalog to page 8All Keller Lufttechnik GmbH + Co. KG catalogs and technical brochures

-

AmbiTower

4 Pages

-

JET-SET

4 Pages

-

PT-Filter

4 Pages

-

VARIO eco

8 Pages

-

Exhaust hoods/nozzle plates

2 Pages

-

Volume flow regulator ProFix

4 Pages

-

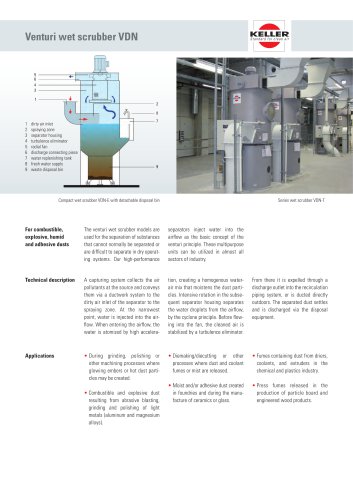

Wet scrubber VDN

12 Pages

-

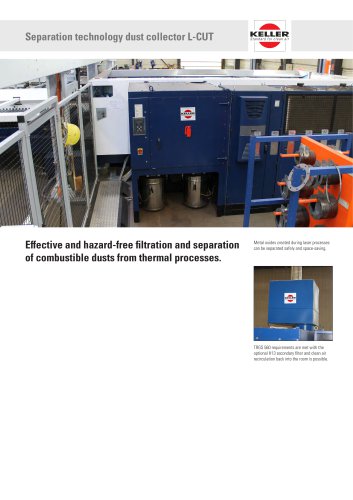

Dry separator L-CUT

4 Pages

-

Dry separator VARIO 2014

12 Pages

-

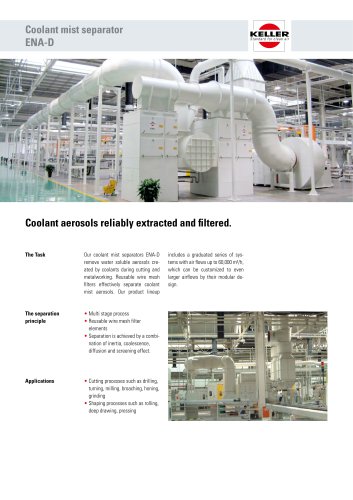

Coolant mist separator ENA-D

8 Pages

-

Movable extractor arms

2 Pages