Website:

KEB Automation KG

Website:

KEB Automation KG

Group: KEB

Catalog excerpts

Input AC 3PH 50/60 Hz 400V XXXXXX Output: AC3PH 0…U XXXXXXX XXXkVA / XXXX Mat.No. 0000000-0000 Cust.No. CAUTION Risk of Electrical Shock Capacitors discharge time is 5 minutes. A fault protective switch is not permissible as the only protective measure! CNC SOLUTIONS IDEALLY MATCHED HARDWARE AND SOFTWARE COMPONENTS EN

Open the catalog to page 1

CNC SOLUTIONS CNC KERNEL Scalable entry-level or high-end CNC solution COMBIVIS studio 6 Automation tool for CNC, PLC, safety and drives COMBIVIS studio HMI CNC visualization COMBIVIS CLOUD Ready for IoT COMBIVIS CONNECT Remote maintenance SEAMLESS INTEGRATION In order to create a complete CNC solution, a consistent concept of coordinated hardware and software components is required. This starts with IPC-based control technology and fitting visualization, extends to drive controllers with integrated safety up to motors and gears. System solutions from a single source simplify...

Open the catalog to page 2

EMBEDDED CONTROLS IPC CONTROLS Scalable real time control solutions REMOTE I/O SAFETY PLC EtherCAT based I/O system, Safety over EtherCAT DRIVE UNITS Modular drive systems Input AC 3PH 50/60 Hz 400V XXXXXX Output: AC3PH 0…U XXXXXXX XXXkVA / XXXX Mat.No. 0000000-0000 Cust.No. CAUTION Risk of Electrical Shock Capacitors discharge time is 5 minutes. A fault protective switch is not permissible as the only protective measure! FILTER Flexible mains and motor filters MOTORS Extensive range of motors Ideally matched hardware and software solutions CNC kernels with extensive function packages...

Open the catalog to page 3

CNC VISUALIZATION The CNC solutions contain the complete CNC visualization in a user-friendly interface. The HMI interface is designed for intuitive operation with multitouch and offers convenient features for the operation of CNC applications. The associated commissioning wizard guides the user from the reference point run to the determination of the up to 100 zero points of the workpiece and, if necessary, machine coordinate systems to the parameterization of the CNC program and all necessary machine settings. This enables even users with less experience to start a machine program without...

Open the catalog to page 4

ENTRY-LEVEL SOLUTION CNC SOLUTION WITH KEB KERNEL The flexible and scalable system solution with integrated KEB CNC kernel consists of control, visualization, safety technology, drives and motors. It enables various applications in the field of CNC. • • • • • • Up to eleven interpolating axes in the Cartesian coordinate system No limit for non-interpolating axes in the bus network for all scaling in the CNC program Scalability of CNC controllers -- Embedded controls as an economical solution -- IPC technology for higher demands on cycle time Orientation at the Tool Center Point (TCP) as...

Open the catalog to page 5

HIGH-END SOLUTION COMBIVIS studio 6 Automation tool with object-oriented design High-end solution KEB extention package FAST AND PRECISE PATH PLANNING For complex requirements, the high-end solution with the integrated ISG CNC kernel offers extensive features for CNC, robotics and motion control. Systems with up to 64 axes are possible for the realization of a CNC application. Depending on the requirements, the number of axes or channels can be increased. Extensive function packages are available for this purpose. The user has the possibility to access on a database with various...

Open the catalog to page 6

CNC SOLUTION WITH ISG KERNEL For the implementation of high-end applications, the ISG CNC kernel was implemented on real-time IPC controllers. The flexible and scalable system solution, consisting of control, visualization, safety technology, drives and motors, enables various applications in the field of CNC. The functional scope offers solutions for machine tools as well as the movement of complex kinematics. The functions are used, for example, in applications such as milling, drilling, cutting, grinding, bending and associated handling systems. BASIC PACKAGE The basic package of the...

Open the catalog to page 7

KEB Automation KG Südstraße 38 32683 Barntrup Germany Tel. +49 5263 401-0 E-Mail: info@keb.de © 0000000-5CNC 09.2019 Subject to technical alterations!

Open the catalog to page 8All KEB Automation KG catalogs and technical brochures

-

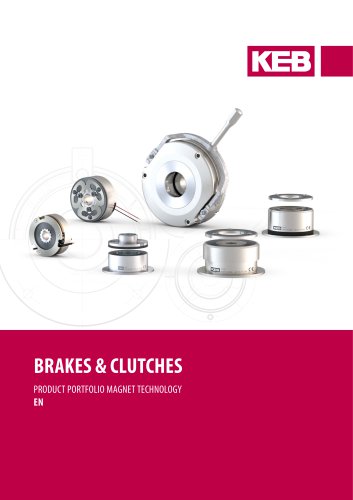

BRAKES & CLUTCHES

52 Pages

-

COMBIVERT F6

18 Pages

-

CONTROL AND AUTOMATION

264 Pages

-

BRAKES & CLUTCHES

52 Pages

-

13F6A12-3A11

1 Pages

-

12F6K1D-3AMA

1 Pages

-

12F6A12-3A11

1 Pages

-

SOLUTION SERVO PUMP

8 Pages

-

PORTFOLIO 2020

8 Pages

-

MP IE4 MOTORS

44 Pages

-

C6 ROUTER

10 Pages

-

Safety PLC & Safety I/O

6 Pages

-

I/O System

19 Pages

-

C6 AMM

6 Pages

-

C6 Monitor

6 Pages

-

C6 P34 BM

6 Pages

-

C6 E22 BM

6 Pages

-

C6 P34 Box

6 Pages

-

C6 E22 Box

6 Pages

-

C6 P34 Panel

6 Pages

-

C6 E22

6 Pages

-

C6 SMART

6 Pages

-

C6 COMPACT

6 Pages

-

C6 S14

6 Pages

-

C6 HMI-LC

6 Pages

-

C6 HMI

6 Pages

-

COMBIVERT F6-K

12 Pages

-

Servo Motors

16 Pages

-

COMBIVERT R6

8 Pages

-

Electromagnetic Technology

54 Pages

-

COMBILINE

28 Pages

-

COMBIVERT F5

32 Pages

-

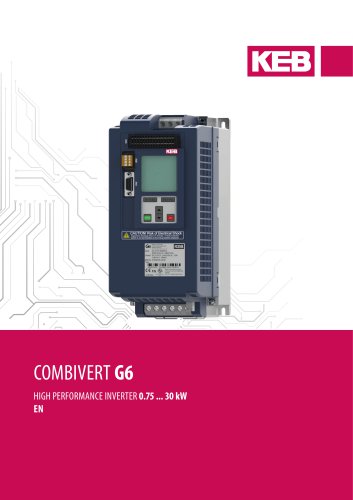

COMBIVERT G6

16 Pages

-

COMBIVERT H6

24 Pages

-

COMBIVERT F6

16 Pages

-

COMBIVERT S6

24 Pages

-

PRODUCT PORTFOLIO 2018

8 Pages

-

SYSTEM FOR SAFETY

8 Pages

-

CONTROL AND AUTOMATION

212 Pages

-

KEB DRIVE

130 Pages

Archived catalogs

-

COMBICONTROL C6

36 Pages

-

Control & Automation

68 Pages