Website:

KEB Automation KG

Website:

KEB Automation KG

Group: KEB

Catalog excerpts

DRIVE BASED SAFETY COMBIVERT S6 COMPACT SERVO DRIVES EN

Open the catalog to page 1

System overview Functional Safety Electrical properties Mechanical data, operating types, standards Planetary gear Servo Gear Motors

Open the catalog to page 2

SYSTEM OVERVIEW Automation with Drive stands as a synonym for optimally selected combinations of control and automation solution. With the drive level at the end it is the key to successful machine concepts. Let the following pages inspire you with regards to the diversity and p erformance of the COMBIVERT S6 servo system, and help you to find a solution that reliably meets your requirements. SOFTWARE Mobile APP Visualisation Cloud services Remote Control CLOUD ROUTER RESET RUN / STOP COM Rx CONNECT ROUTER POWER REMOTE CONNECT REMOTE CONNECT Embedded Control Input AC 3PH 50/60 Hz 400V...

Open the catalog to page 3

COMBIVERT S6 - BENEFITS AT A GLANCE OPTIMALLY SELECTED COMPONENTS The COMBIVERT S6 servo system adds a compact, flexible and powerful drive module to the KEB product portfolio for highly dynamic servo applications. The optimally selected KEB components are the key to this successful drive concept. At the heart, the innovative S6 servo drive is offered in an attractive book-style format and offers real-time performance. The S6 drives can be matched with the robust DL3 servo motors which are available in five sizes. Additionally, the DL3 servo motors may be paired with planetary gearheads...

Open the catalog to page 4

DRIVE BASED SAFETY ALL IN ONE - UNIVERSAL MOTOR OPERATIONS Integrated Safety functionality Basic function STO in Compact version Additional modular High level Safety in Application version Encoderless safety in version PRO Control for asynchronous, synchronous, IPM or synchronous reluctance motors Motor operation with encoder feedback or encoderless ASCL / SCL for precise speed control Motor temperature monitoring with PTC, KTY or PT1000 sensors Two-channel multi-encoder interface Integrated brake transistor Integrated brake control and brake supply REAL-TIME COMMUNICATION • Real-time...

Open the catalog to page 5

COMBIVERT S6 I/0 8 digital inputs 2 digital outputs 1 relay 2 analog inputs 1 analog output 24V DC supply MAINS CONNECTIONS with pluggable terminals FUNCTIONAL SAFETY DIAGNOSTIC INTERFACE STATUS LEDS REALTIME ETHERNET MULTI ENCODER INTERFACES Resolver, EnDAT, Hiperface, BISS, SSI, Incremental HTL / TTL, Incremental output DC SUPPLY TERMINALS and braking resistor KTY / PTC / PT1000 EVALUATION BRAKE CONTROL 24 V / 2 A MOTOR TERMINALS with pluggable terminals Safety over Compact and flexible servo system Highest performance in torque, speed and position control Uncompromising integration...

Open the catalog to page 6

COMPACT HIGHLY INTEGRATED AND ECONOMICAL APPLICATION MODULAR AND FLEXIBLE STO, SBC and speed / position related safety functions STO, SBC and speed related safety functions without encoder feedback REALTIME ETHERNET REALTIME ETHERNET REALTIME ETHERNET ETHERCAT (FSoE) PROFINET POWERLINK ETHERNET / IP ETHERCAT (FSoE) Communication interface Communication interface Communication interface Brake handling Power-off DC-brake PID controller Round table function Recipe management Multi motor handling Anti cogging Management liquid

Open the catalog to page 7

SAFETY FUNCTIONS IN THE DRIVE BASIS FOR SAFETY COMPACT In the Compact version, the COMBIVERT F6 and S6 drive controllers are equipped with Safe-Torque-Off (STO). SAFETY FUNCTIONS WITH SPEED AND POSITION MONITORING APPLICATION The device variant Application is available in two versions. In addition to STO, Module 1 adds safe brake control (SBC) which provides a safe 24 V supply for the brakes. Module 3 offers safe motion functionality according to IEC 61800-5-2 through speed and position detection using encoders. The error reaction time is shortened and costs are reduced by reducing the...

Open the catalog to page 8

ENCODERLESS SAFETY FUNCTIONS PRO The PRO device variant of the COMBIVERT F6 and S6 drive controllers offers advanced safety functions without having to use a safety encoder. The device determines the safe velocity parameters from the pulse width modulation (PWM) of the motor supply. In addition to STO, Module 5 is equipped with a safe brake control (SBC), which provides a safe 24 V supply for braking operation as well as a monitoring of the switching status of the brake via microswitch evaluation. Module 5 also offers the option of controlling all available safety functions via Safety over...

Open the catalog to page 9

COMBIVERT S6 ELECTRICAL PROPERTIES HOUSING Device size Mains phases Output rated current Short maximum current (3 s / 60 s) 1) Output rated power * Typical rated motor power 230 V Max. current 0 Hz / cutoff frequency at fs = 4 kHz Cutoff frequency point Input rated current Rated switching frequency Standby losses Input rated voltage (AC) Input voltage range (AC) 2) Input voltage range (DC) Mains frequency Output voltage Output frequency Max. current 0 Hz / cutoff frequency at fs = 8 kHz 1) Max. current 0 Hz / cutoff frequency at fs = 16 kHz Max. permissible mains fuses Rated losses The...

Open the catalog to page 10

TECHNICAL DATA OPERATING TYPES, STANDARDS OPERATING MODES PMSM: field-oriented with encoder, S.C.L. encoderless IPMSM: field-oriented with encoder, S.C.L. encoderless SyncRM: field-oriented with encoder, S.C.L. encoderless ASM: V / F, field-oriented with encoder, A.S.C.L. encoderless CiA 402 Velocity Mode Cyclic Synchronous Velocity Mode Cyclic Synchronous Torque Mode Cyclic Synchronous Position Velocity Mode Profile Position Mode Homing Mode Jog Mode Motor control mode Application profile Control mode GENERAL Product standard EMC transient emissions EN 61800-2, -5-1 EN 61800-3, C2 - 1-ph:...

Open the catalog to page 11

SERVO MOTORS SERVOMOTORS DYNAMIC LINE 3 E_SMH__ MOTOR 0.2 ... 29 Nm in six frame sizes Low inertia – high impulse torque Resolver or absolute rotary encoder, HIPERFACE single or multi-turn High degree of total efficiency Lifetime lubricated Universal installation positions Robust mechanics (optional: COMBIPERM holding brake, keyway with key, IP65 s

Open the catalog to page 12

MATCHED WITH COMBIVERT S6 PLANETARY GEAR SG PAIRED WITH DYNAMIC LINE 3 GEAR SIZE BACKLASH arcmin SIMPLE SELECTION AND ORDERING BY SYSTEM CONFIGURATION IN COMBIVIS 6 • • • Output torque and speed Gear ratio Motor size Low backlash High output torque High efficiency (97 %) Gear ratios i = 5 to 40 Low audible noise Life

Open the catalog to page 13All KEB Automation KG catalogs and technical brochures

-

SERVO MOTORS TA

24 Pages

-

COMBIVERT P6

16 Pages

-

COMBIVERT T6

4 Pages

-

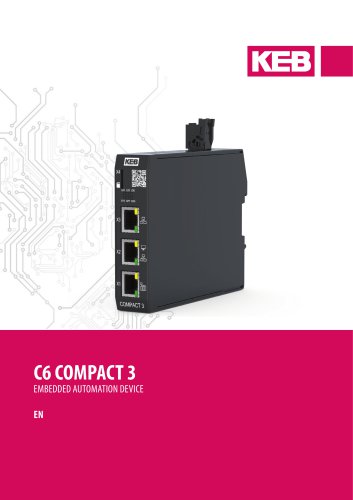

C6 COMPACT 3

4 Pages

-

CONTROL AND AUTOMATION

264 Pages

-

SOLUTION SERVO PUMP

8 Pages

-

CNC SOLUTIONS

6 Pages

-

EMC COMBILINE

32 Pages

-

DL3 Servo Motors

16 Pages

-

COMBIVERT G6

16 Pages

-

COMBIVERT R6

8 Pages

-

SYSTEM FOR SAFETY

12 Pages

-

BRAKES & CLUTCHES

40 Pages

-

PORTFOLIO

8 Pages

-

COMBIVERT F6

18 Pages