Catalog excerpts

Powering your potential Kawasaki Robot Kawasaki Heavy Industries, Ltd. Robot Business Division Tokyo Head Offlce/Robot Division 1-14-5, Kaigan, Minato-ku, Tokyo 105-8315, Japan Phone: +81-3-3435-2501 Fax: +81-3-3437-9880 Akashi Works/Robot Division 1-1, Kawasaki-cho, Akashi, Hyogo 673-8666, Japan Phone: +81-78-921-2946 Fax: +81-78-923-6548 Global Network Kawasaki Robotics (USA), Inc. 28140 Lakeview Drive, Wixom, MI 48393, U.S.A. Kawasaki Robotics (UK) Ltd. Unit 4 Easter Court, Europa Boulevard, Westbrook Warrington Cheshire, WA5 7ZB, United Kingdom Phone: +44-1925-71-3000 Fax: +44-1925-71-3001 Kawasaki Robotics GmbH Im Taubental 32, 41468 Neuss, Germany Phone: +49-2131-34260 Fax: +49-2131-3426-22 Kawasaki Robotics Korea, Ltd. 43, Namdong-daero 215beon-gil, Namdong-gu, Incheon, 21633, Korea Phone: +82-32-821-6941 Fax: +82-32-821-6947 Kawasaki Robotics (Tianjin) Co., Ltd. 1-2/F, Building 6, No.19 Xinhuan Road, TEDA, China Phone: +86-22-5983-1888 Fax: +86-22-5983-1889 Kawasaki Motors Enterprise (Thailand) Co., Ltd. (Rayong Robot Center) 119/10 Moo 4 T.Pluak Daeng, A.Pluak Daeng, Rayong 21140 Thailand Phone: +66-38-955-040-58 Fax: +66-38-955-145 https://robotics.kawasaki.com/ Kawasaki Robot CAUTIONS TO BE TAKEN TO ENSURE SAFETY •For those persons involved with the operation / service of your system, including Kawasaki Robot, they must strictly observe all safety regulations at all times. They should carefully read the Manuals and other related safety documents. •Products described in this catalogue are general industrial robots. Therefore, if a customer wishes to use the Robot for special purposes, which might endanger operators or if the Robot has any problems, please contact us. We will be pleased to help you. •Be careful as Photographs illustrated in this catalogue are frequently taken after removing safety fences and other safety devices stipulated in the safety regulations from the Robot operation system. ] Materials and specifications are subject to change without notice.

Open the catalog to page 1

Standard specifications Kawasaki’s high-speed palletizing robots meet the demands for flexibility and speed. Degrees of freedom (axes) flexible packaging, the freshest products, or the highest production line efficiencies can be crucial automation systems for the end-of-line and distribution processes of palletizing and depalletizing. Kawasaki’s robotic palletizing solutions provide the pallet pattern flexibility, tooling flexibility, and cycle times needed to deal with multi-variety and small-batch production, and reduce process change costs. Kawasaki Robotics offers tow different lines of...

Open the catalog to page 2

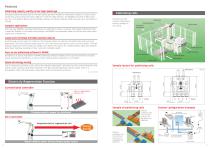

Features Palletizing capacity worthy of our high-speed age Kawasaki palletizing robots deliver the high-speed operation needed for distribution. Based on a robot stroke of 400 mm upward-downward and 2,000 mm in the left-right direction, the RD080N can perform 900 cycles per hour with loads of 80 kg, and the CP180L achieves an industry leading 2,050 cycles per hour with loads of 130 kg. Compact applications Palletizing cells Kawasaki provides system configurations perfectly adapted to your needs. The Kawasaki RD080N is designed specifically for applications where a compact, high-speed,...

Open the catalog to page 3

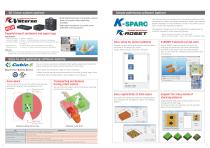

3D Vision system (option) Simple palletizing software (option) ○Initial adjustment work is drastically reduced This software lets you configure the pick and place positions of the workpieces by robots and register workpieces, pallets, and stacking patterns displayed on your computer’s screen. It also allows you to easily create robot operation programs . thanks to suitable robot application packages. ○High-speed recognition is possible using dedicated vision equipment. This optional software is one of the application programs built on K-ROSET, Kawasaki’s offline teaching software....

Open the catalog to page 4

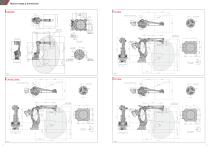

Motion range & dimensions Rear side interference area 170 Working range based on point P Base installation dimensions Base installation dimensions 400 Motion range of point "P" Rear side interference area Working range based on point P Base installation dimensions Base installation dimensions Working range based on point P 474 Rear side interference area

Open the catalog to page 5

Teach pendant The E Controller combines high performance, unprecedented reliability, a host of integrated features and simple operation, all in a compact design. Features Compact The E03 controller for CP series palletizing robots has far less volume. You can use it in an upright-position or in a stacked installation to reduce the footprint of this controller. User-friendly operation The easy-to-use teach pendant now incorporates motor power and cycle start at your fingertips. Multiple information screens can be displayed simultaneously. The intuitive teaching interface is simple to...

Open the catalog to page 6All Kawasaki Robotics GmbH catalogs and technical brochures

-

B Series Spot welding robots

6 Pages

-

Lineup Overview

2 Pages

-

MS005N

2 Pages

-

Kawasaki Robot K series

12 Pages

-

Kawasaki Robot Y series

6 Pages

-

Kawasaki Vision System

2 Pages

-

MC series

2 Pages

-

Dual-arm SCARA Robot “duAro”

6 Pages

-

F60 Controller

2 Pages

-

Controllers

1 Pages

-

Kawasaki CX Series robots

4 Pages

-

Clean Robot NTS, TTS series

2 Pages

-

Kawasaki Robot duAro 2

2 Pages

Archived catalogs

-

Controller

1 Pages

-

Kawasaki Vision System

2 Pages

-

K-SPARC PALLETIZING SOFTWARE

2 Pages

-

MC004N

5 Pages

-

Kawasaki Dual Arm Scara

2 Pages

-

Kawasaki Clean robots

6 Pages

-

Kawasaki B Series robots

6 Pages

-

M-Series

5 Pages

-

Z-Series

7 Pages

-

CX series

2 Pages

-

R-Series

7 Pages

-

Lineup

8 Pages

-

MC/MS-Series

5 Pages

-

Overview

2 Pages

-

K-Roset

4 Pages

-

Cubic-S

3 Pages

-

Palletizer

5 Pages

-

Y-Series

5 Pages

-

RA-Series

5 Pages

-

RS80N

2 Pages

-

RS50N

2 Pages

-

RS30N

2 Pages

-

RS20N

2 Pages

-

RS10L

2 Pages

-

RS10N

2 Pages

-

RS06L

2 Pages

-

RS05L

2 Pages

-

RS05N

2 Pages

-

RS03N

2 Pages

-

RS15X

2 Pages

-

Metal Fabrication Automation

4 Pages

-

FSJ

4 Pages

-

PC Roset

2 Pages

-

Y Series

6 Pages

-

Z-Series

8 Pages

-

R series

8 Pages

-

E controller

2 Pages

-

D-Controller

6 Pages

-

EDU Pack

2 Pages

-

FD/ZD/MD Series Palletizer

4 Pages

-

Image Catalogue

5 Pages

-

Line up

8 Pages