Catalog excerpts

Kawasaki Robot

Open the catalog to page 1

Our Product Philosophy is “Simple and friendly” With more than 50 years experience in industrial robotics, we have consolidated our "state-of-the-art" technologies into productivity enhancing flexible automation solutions that are simple and friendly. Our product lineup offers comprehensive functionality with operational ease of use. Kawasaki began the manufacture and sales of industrial robots in 1969. Since that time, we have consistently produced high quality, cost effective industrial robots featuring state-of-the-art technology for both the domestic and overseas markets. Our broad...

Open the catalog to page 2

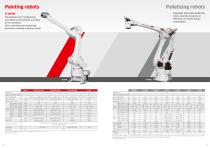

Medium payload robots up to 210 kg R series Setting the benchmark in its class - higher speed and longer reach in a compact design. CX series Kawasaki’s latest technology delivers increased robot motion speed and installation flexibility. Application: • Assembly • Dispensing • Machine tending • Material handling • Material removal • Palletizing • Arc welding Application: • Assembly • Material handling • Palletizing • Spot welding

Open the catalog to page 3

Medium payload robots up to 300 kg large payload robots up to 1.500 kg Z series Robust low-maintenance design with wide work envelope provides application flexibility. M series Achieves high wrist torque and payload capacity without any counterweights for a wide motion range and compact footprint. ]1: conforms to ISO9283 ]2: depends on payload Application: • Machine tending •

Open the catalog to page 4

Arc welding robots B series High speed spot welding with greater spot control. Space saving design supports “high density” applications. BA/RA series Kawasaki robots use the latest arc welding technology to rival the quality of a skilled human welder. ]1: conforms to ISO9283 Application: • Spot welding

Open the catalog to page 5

Palletizing robots K series The optimum wrist configuration and model can be selected according to the workpiece. Servo controlled part positioning equipment available (explosion proof). Kawasaki’s high-speed palletizing robots meet the demands for flexibility on reduced energy consumption. *1: Motion pattern (400mm up, 2,000mm horizontal, 400mm down in a to-and-fro motion) *2: conforms to ISO9283 *3: operating angle of the JT5 is ±10 degrees perpendicular to the ground. *4: in case of 130 kg payload and less *5: in case of 250 kg payload and less Application: • Palletizing

Open the catalog to page 6

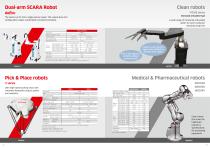

Clean robots duflro The duAro can fit into a single-person space. The coaxial dual-arm configuration makes coordinated movements possible. NT/NS series Horizontal Articulated type A wide range of horizontal articulated robots for semi-conductor manufacturing lines *1: Specification varies in case of other options or conversion Application: • Assembly • Material handling • Machine tending • Dispensing Fastest in the industry! Higher than 500WPH is possible with option. First in the industry! 4 FOUPs without traverse truck. Pick & Place robots Y series Medical & Pharmaceutical robots Ultra...

Open the catalog to page 7

Kawasaki Robotics Options: Individual Additions for Your Robots Safety Modules, Software Solutions, External Axes and more: Kawasaki Robotics offers an extensive range of application-specific options for our robots and controllers – allowing you to precisely adapt each Kawasaki robot to your individual needs and to maximize its performance. Selection of Hardware Options Cubic-S Conveyor Tracking The Kawasaki Robotics Cubic-S safety module enables you to individually define and precisely limit the available working space. With Cubic-S, extremely space-saving application cells are easily...

Open the catalog to page 8

KAWASAKI ROBOTICS OPTIONS Additional Input/Output Boards Sensor Harness Harnesses for setting up a signal connection of grippers to the Arm-ID Board. The external box provides additional inputs and outputs. The digital version offers 32 Digital IOs while the analogue version offers 4 inputs and 4 outputs. A maximum of six boxes, 4 digital and 2 analogue, can be connected to one controller. The boxes offer a variety of mounting options such as brackets on all sides or top-hat rail mounting. The unit is configurable as NPN and PNP – including 2AW or 2AH boards. Our space-saving, sturdy and...

Open the catalog to page 9

KAWASAKI ROBOTICS OPTIONS Selection of Software Options Collision Detection This option allows the monitoring of motor current values according to selectable thresholds. Different values can be defined for manual and automatic operation of each robot. This option can reduce the damage caused by collisions significantly. K-IDE is an intuitive programming interface for Kawasaki robots, enabling the precise development of programs for numerous applications and systems. The easy to use editor, the clearly arranged project management, the automatic synchronization between software and robots and...

Open the catalog to page 10

Kawasaki Robotics Options: Adapt each robot to your individual needs Color LCD teach pendant for the E and F series controllers ler ded ) trol e Con ler ne ot l Rob ontro (via nal C itio a dd ) (via Vision Server (EtherNet/IP er (F60)) or directly to the Robot Controll Vision System & Conveyor Tracking EOX-Controller (via Offline Programming (via Multi Axis Controller) The teach pendant has a significantly lighter body with an optimized weight balance that reduces the burden of teaching work. The operator can now switch on the motors and activate the cycle start all from the teach pendant....

Open the catalog to page 11

Controller Combines high performance, unprecedented reliability, a host of integrated features and simple operation all in a compact design. The enhanced CPU capacity allows for more accurate trajectory control and faster application program execution.

Open the catalog to page 12

As individual and reliable as our robots: Our Service The Kawasaki Robotics Service Program • o guarantee maximum availability of your robots and systems, our experts T are available 24/7 - via our technical hotline and, of course, on site. Kawasaki Robotics provides numerous options for comprehensive technical support – with or without a maintenance contract. • ustomers benefit from our international network, cross-industry expertise C and excellent service. • e help to avoid downtimes through fast fault analyses and predictive W maintenance. • ur 24/7 Phone Support O • ailor-made service...

Open the catalog to page 14All Kawasaki Robotics GmbH catalogs and technical brochures

-

B Series Spot welding robots

6 Pages

-

Lineup Overview

2 Pages

-

MS005N

2 Pages

-

Kawasaki Robot K series

12 Pages

-

Kawasaki Robot Y series

6 Pages

-

Kawasaki Vision System

2 Pages

-

Palletizing robots

6 Pages

-

MC series

2 Pages

-

Dual-arm SCARA Robot “duAro”

6 Pages

-

F60 Controller

2 Pages

-

Controllers

1 Pages

-

Kawasaki CX Series robots

4 Pages

-

Clean Robot NTS, TTS series

2 Pages

-

Kawasaki Robot duAro 2

2 Pages

Archived catalogs

-

Controller

1 Pages

-

Kawasaki Vision System

2 Pages

-

K-SPARC PALLETIZING SOFTWARE

2 Pages

-

MC004N

5 Pages

-

Kawasaki Dual Arm Scara

2 Pages

-

Kawasaki Clean robots

6 Pages

-

Kawasaki B Series robots

6 Pages

-

M-Series

5 Pages

-

Z-Series

7 Pages

-

CX series

2 Pages

-

R-Series

7 Pages

-

Lineup

8 Pages

-

MC/MS-Series

5 Pages

-

Overview

2 Pages

-

K-Roset

4 Pages

-

Cubic-S

3 Pages

-

Palletizer

5 Pages

-

Y-Series

5 Pages

-

RA-Series

5 Pages

-

RS80N

2 Pages

-

RS50N

2 Pages

-

RS30N

2 Pages

-

RS20N

2 Pages

-

RS10L

2 Pages

-

RS10N

2 Pages

-

RS06L

2 Pages

-

RS05L

2 Pages

-

RS05N

2 Pages

-

RS03N

2 Pages

-

RS15X

2 Pages

-

Metal Fabrication Automation

4 Pages

-

FSJ

4 Pages

-

PC Roset

2 Pages

-

Y Series

6 Pages

-

Z-Series

8 Pages

-

R series

8 Pages

-

E controller

2 Pages

-

D-Controller

6 Pages

-

EDU Pack

2 Pages

-

FD/ZD/MD Series Palletizer

4 Pages

-

Image Catalogue

5 Pages

-

Line up

8 Pages