Website:

KARL DEUTSCH

Website:

KARL DEUTSCH

Catalog excerpts

Definitely Tested! DEUTROFLUX / DEUTROMAT Magnetic Particle Testing Systems

Open the catalog to page 1

KARL DEUTSCH Pruef- und Messgeraetebau, Wuppertal Company Portrait The company KARL DEUTSCH was founded by Ing. Karl Deutsch in 1949. Since the early 1950‘s, instruments, magnetic inks and testing systems for magnetic particle testing have been developed and produced. Three application laboratories chanical and electrical construction, as well as PLC-programming are carried out in-house. This provides one-stop quirements. A modular mechanical design is the base of our modern testing systems. Normally, multiple AC circuits are provided and water-based FLUXA concentrates (magnetic inks) are...

Open the catalog to page 2

Most application problems in magnetic particle testing can be solved by testing systems with two contacts (yoke magnetization principle). Often the parts to be tested are manually placed into the respective supports of the testing system. Afterwards, it pneumatically clamps the test piece. The next step comprises magnetization and spraying with magnetic ink. This usually takes about 4 seconds. Water-based concentrates are commonly used and sprayed by nozzles onto the workpieces. Usually a multi-directional magnetization is employed. A longitudinal current is fed through the test piece and...

Open the catalog to page 3

The HW testing system provides a circular magnetization produced by a direct current flow for the detection of longitudinal cracks (e. g. for wire testing). The system contains a fixture for two mobile UV-LED lamps which can be easily removed for flexible evaluation of all test piece surfaces. The EW testing system offers multi-directional magnetization (2 separate field circuits) and is available in two lengths (300 mm and 600 mm). kahideutsch The UWE 350 testing system provides clamping lengths of up to 350 mm. This example shows a mobile test bench with a motorized adjustment of the...

Open the catalog to page 4

DEUTROFLUX Workpiece Holders for Test Benches with Two Contacts Workpiece holder and special contact for spindle Workpiece holder and special contact for testing of small parts Testing of hollow parts with a magnetization bar and a plastic roller support for Workpiece holder for complex-shaped casting Roller support for shaft testing. In this case the shaft is turned manually. Hollow part testing with side-mounted magnetization bar. The surface of The same workpiece holder, now empty. Nozzles for Rotary workpiece holder with middle contact for piston rod testing

Open the catalog to page 5

Workpieces with a length above 900 mm can not be satisfactorily tested with testing systems where the longitudinal fields are produced by side-mounted coils (principle of yoke magnetization). While the current magnetization and the respective circular magnetic field for longitudinal defect detection is constant for the entire workpiece length (for constant diameter), the longitudinal field for transverse defect detection is too weak in the center region of the workpiece. Therefore, a moving coil is employed, which fully surrounds the workpiece. The magnetic ink is sprayed onto the workpiece...

Open the catalog to page 6

Inspection of a large shaft for power generation. This UWS testing system is equipped with a heavy duty traverse in order to handle large workpiece weights. The traverse and the workpiece are both surrounded by the moving coil. Additional side-mounted coils (UWE magnetization principle) are added to this UWS testing system. Therefore, this machine can be used for short or long workpieces, respectively. The picture shows a pinion shaft and a gear wheel for power generation. The inspection of these large hooks is carried out with a moving coil and three current contacts. The inspection of...

Open the catalog to page 7

This truck steering knuckle is tested with four contacts. The workpiece loading is carried out with a robot. The steering knuckles are discharged towards the rear of the testing system by means of two height adjustable heavy duty chain belts. Forgings of complex shape can be magnetized in this testing system with up to four current contacts and a moving coil. The shown transverse link requires a coil and three current contacts. Testing systems in turn table design allow efficient loading and discharging, e. g. by means of a robot. This turn table for crankshafts provides four stations:...

Open the catalog to page 8

The requirements concerning documentation and level of automation are constantly increasing. The DEUTROFLUX MEMORY PLC software is therefore an important tool. Relevant test parameters, test time, test result and - where necessary -name of operator etc. can be managed and documented by the Siemens PLC software. Password protection for some parameters can prevent operating errors. Regular service intervals or the supervision of magnetic ink or UV lamps can be monitored by the PLC software. In-house PLC programming provides flexible implementation of cus- As needed, mobile touch panels are...

Open the catalog to page 9

Magnetic particle testing is a common method in various fields of industry. Many customers are from the automotive industry, where forgings are tested for surface cracks directly after their production. Railway and aerospace components are often tested in new condition, but also in the maintenance workshops at regular checking intervals. Also the power generation industry requires a wide range of tests on shafts, bearings and gears. This picture shows a testing system for new railway wheels. The system is part of a fully automated production and inspection line. A workpiece carriage...

Open the catalog to page 10

The inspection of a large pinion shaft with a weight of 4 tons is carried out by means of a specially designed moving coil. Large gear wheels for wind turbines can be inspected with a crossyoke arrangement or with a yoke pair and coil. This HW testing system with direct current magnetization for steel bar testing allows rotation and visual evaluation directly in the system. Seamless tubes can be linearly fed through a combination of magnetizing yoke pair and coil. The inspection of railway springs uses a combination of direct current magnetization and magnetization bar. This picture shows...

Open the catalog to page 11All KARL DEUTSCH catalogs and technical brochures

-

DEUTROMAT Railway

4 Pages

-

DEUTROMAT Chain Conveyor

4 Pages

-

DEUTROFLUX UWS

4 Pages

-

DEUTROFLUX UWE

6 Pages

-

DEUTROFLUX EW

1 Pages

-

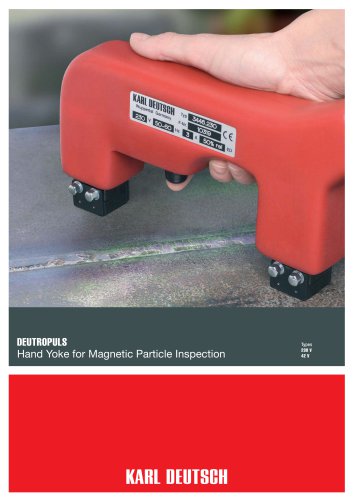

DEUTROPULS

2 Pages

-

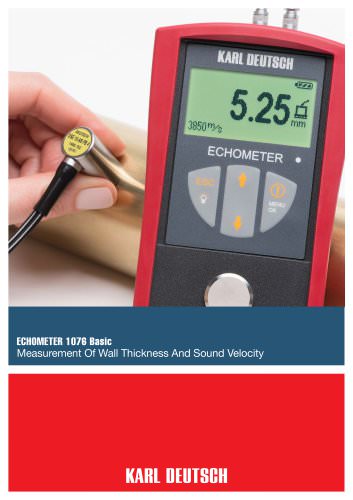

ECHOMETER 1076 Basic

2 Pages

Archived catalogs

-

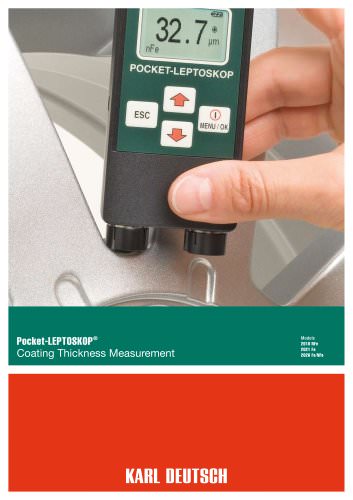

Coating Thickness Gauges

2 Pages

-

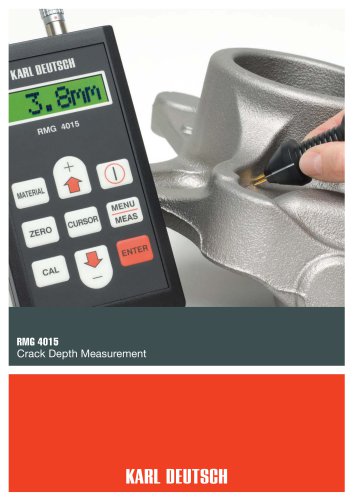

Crack Depth Meter

2 Pages