Website:

Kaltra Innovativtechnik GmbH

Website:

Kaltra Innovativtechnik GmbH

Catalog excerpts

Microchannel Fluid Coils HEAT EXCHANGERS FOR COOLING AND HEATING DESIGN AND SPECIFICATIONS INSTALLATION GUIDELINES MAINTENANCE TECHNICAL MANUAL ENGLISH SPECIAL FLUIDS

Open the catalog to page 1

MICROCHANNEL FLUID COILS CUSTOMER SERVICES Maintenance and Warranty As standard, Kaltra guarantees heat exchangers for a period of 24 months uncoated and 60 months e-coated, variations tailored to suit product and application are also available; please contact Kaltra for full terms and details. For a free quotation contact Kaltra or your local sales engineer. All Kaltra products are designed in accordance with European and international standards and norms. Warranty cover is not a substitute for maintenance. Warranty cover is conditional to maintenance being carried out in accordance with...

Open the catalog to page 2

MICROCHANNEL FLUID COILS SAFETY The information contained in this manual is critical to correct installation and maintenance of heat exchangers and should be read by all persons responsible for the procedures mentioned above. Heat exchangers have been designed and manufactured to meet international safety standards, but care must be taken if you are to obtain the best results. Installation and maintenance work on heat exchangers should be undertaken by competent and trained personnel in accordance with local relevant standards and codes of practice. Improperly installed, adjusted or altered...

Open the catalog to page 3

MICROCHANNEL FLUID COILS Flat Fins Louvered Fins Manifolds Fluid Connections Connection Location Connection Type Connection Orientation Mountings and Fixtures Protective Coatings Epoxy Electrophoretic Coating Trivalent Chromium Process Coating Bending Casings and Assemblies Mounting Airtightness Thermal Expansion Vibrations and Stresses Connecting To Pipework Bending Procedure Fluid Circuit Requirements Fluid Velocity Filtration Process Fluid Requirements

Open the catalog to page 4

MICROCHANNEL FLUID COILS INTRODUCTION Purpose of Present Manual The purpose of the present manual is to guide engineers through the selection process of microchannel fluid coils subject to application, operating and environmental requirements and conditions. The manual provides Kaltra customers with recommendations for coil installation, operating parameters, maintenance, and troubleshooting. The development and improvement of Kaltra microchannel heat exchanger products are continuous, and the information in the present manual may not be up to date. Please check the current position with...

Open the catalog to page 5

MICROCHANNEL FLUID COILS The product label identifies the product and provides essential information about the product and its use, including design specification, internal coil volume, design pressure and temperature. The product label is affixed to one of the heat exchanger manifolds. MCHE Application Tube arrangement Fluid coil Tube width Tube thickness Number of tube ports Manifold diameter Manufacturer S/N: Manufacturing date: Refrigerant type(s): Internal volume: Design pressure: Design temperature: Viktualienmarkt 8 • 80331 • München • Deutschland www.kaltra.com • info@kaltra.de...

Open the catalog to page 6

MICROCHANNEL FLUID COILS HEAT EXCHANGER DESIGN Microchannel coil is designed with the fluid inlet and outlet round tube manifolds and flat multiport tubes extending between them, and airside fins of louvered or flat design. Components of the coil are metallurgically bonded together using controlled-atmosphere brazing (CAB) furnace. Depending on application requirements, design engineers may pick up the suitable flat-tube size and configuration, manifold diameter and wall thickness, type of airside fins, fluid connections, type and location of mountings. Protective anti-corrosion surface...

Open the catalog to page 7

MICROCHANNEL FLUID COILS General specifications Property Tube width Tube spacing Manifold diameters Design pressure Burst pressure FLAT / LOUVERED Process fluids WATER / GLYCOLS / OILS / SPECIAL Protective coatings NONE / E-COATING / TCP-COATING Materials Material properties are crucial for heat exchanger durability and corrosion resistance, especially when it comes to operating in aggressive atmospheres like highly-polluted industrial and urban areas, coastal zones, and other corrosive environments. To achieve the highest product performances, Kaltra uses aluminum alloys and clads of...

Open the catalog to page 8

MICROCHANNEL FLUID COILS Microchannel Tubes Heat exchangers can be configured and manufactured with flat microchannel tubes - also referred to as multiport extrusion (MPE) tubes - of different widths, geometry, port quantity, and port sizes, depending on customer requirements, fluid type, and performance demands. Standard or long-life aluminum alloys are the materials for microchannel tubes used in the manufacturing of Kaltra heat exchangers. High manganese-containing, zinc-coated long-life alloys exhibit excellent corrosion properties thanks to the formation of dense band of precipitates...

Open the catalog to page 9

MICROCHANNEL FLUID COILS Louvered Fins The louvered fins enhance the heat transfer by providing multiple flat-plate leading edges with their associated high values of heat transfer coefficient. Louvered fins enhance heat transfer by a factor of 2 to 3 compared with equivalent flat surfaces. The louvers have the further advantage that the enhancement of heat transfer is gained without a significant increase in flow resistance. In louvered fins, fin height, louver angle, number of louvers, louver pitch and fin geometry as a whole are selected for an optimum balance of heat transfer and air...

Open the catalog to page 10

MICROCHANNEL FLUID COILS Manifold specifications - fluid coils Code Tube diameter Wall thickness LOW PRESSURE / MEDIUM PRESSURE HIGH PRESSURE Sectional view HIGH PRESSURE UNIVERSAL / HIGH PRESSURE UNIVERSAL / HIGH PRESSURE Fluid Connections Coils can be configured with fluid connections of different types: copper connections for soldering, flanged, grooved, and threaded stainless steel or carbon steel connections, and aluminum connections. Connection geometry, length, diameter, and location on the coil manifolds are to the customer specification. Connection Location Fluid connections can be...

Open the catalog to page 11All Kaltra Innovativtechnik GmbH catalogs and technical brochures

-

BORA

7 Pages

-

Lamba In-Row CW

4 Pages

-

LAMBDA DX/DXU

4 Pages

-

MISTRAL SERIES

36 Pages

-

BORA SERIES

27 Pages

-

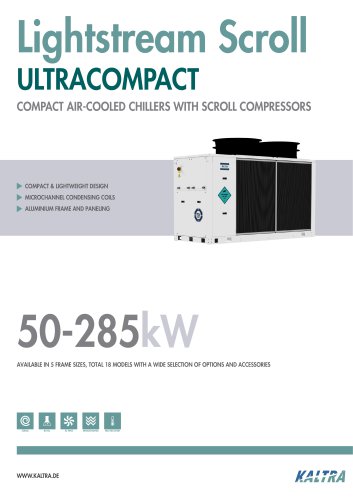

ULTRACOMPACT II

6 Pages

-

ULTRACOMPACT

5 Pages