Website:

Kalt Cheese Technology

Website:

Kalt Cheese Technology

Group: Advaton FoodTec Group

Catalog excerpts

CHEESE PRESSES From the manual Multi Press to the fully automatic, computer-controlled Cassettepress

Open the catalog to page 1

SYSTEM OVERVIEW It’s hard to get more efficient than this: One employee per shift is all it takes to run the entire process of cheese portioning and pressing with the fully automatic Kalt cassette press and to clean the entire plant thoroughly after several batches. However, the Kalt cassette press is not only characterised by its great efficiency, but also by its precision that enables loss-free filling and high weight accuracy in portioning. Since the plant is designed for batch operation, consistently high product quality can be guaranteed as well as strict batch separation and complete...

Open the catalog to page 2

ALL-IN-ONE SYSTEM Five work steps in a single plant The Kalt cassette press performs all five steps involved in the cheese pressing process – from portioning the curd, pressing, acidification, and demoulding the cheese, to CIP cleaning. When the process commences, the curd from the cheese maker is filled directly into the cassette press, rendering the buffer tank obsolete. The moulds and lids will remain in the machine even during CIP cleaning, eliminating any complicated systems and sensors for handling, transporting, and loading the moulds and lids, as well as separate cleaning systems....

Open the catalog to page 3

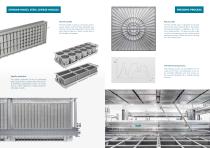

CHROME-NICKEL STEEL CHEESE MOULDS PRESSING PROCESS Kalt press lids The Kalt cassette is made up of several round or square cheese moulds of freely selectable size, lined up side by side. High-quality chrome-nickel steel material makes the cheese moulds particularly durable and hygienic. The Kalt cassette press is designed to precisely meet a wide range of specifications. The respective pressing program is adapted to the customer’s cheese product. The press lids play a special role in the pressing process, as their special perforation ensures uniform removal of the whey from the cheese...

Open the catalog to page 4

CHEESE PRESS TYPES CHEESE VARIANTS Square shapes Round moulds The range covers 30 x 10 cm bread loaf moulds as well as 50 x 30 cm Euroblock formats and moulds for production of cheese sticks with dimensions of 120 x 10 cm. Anything from the small round Tête de Moine with a diameter of 10.5 cm to the Appenzeller with a diameter of 30 cm, or the large Emmentaler with a diameter of 82 cm can be produced. Cassette press The patented Kalt cassette press is designed for single and multi-batch operation. The curd is automatically flushed into the round or square moulds, gently pressed, and...

Open the catalog to page 5

Flush-in press Pre-pressing trough Yoke press The Kalt flush-in press is designed for single and multi-batch operation. Various formats can be produced on a single plant. In contrast to the cassette press, the cheese must be cleared from the flush-in press manually. Volume Application area Loaves and blocks in various formats Conveyor systems/tunnel press Application area Format-independent cake pressing Application area Small quantities or trial plants Reversing Accessories A vast range of optional accessories is available. Dry filler Brand applicator Various formats can be produced on one...

Open the catalog to page 6

An economical and customisable product range that leaves nothing to be desired – in Swiss quality. Our specialists will advise and accompany you through implementation of your projects. Kalt Maschinenbau AG Letziwiesstrasse 8 9604 Lütisburg Switzerland +41 71 932 53 53 www.kalt-ag.ch info@kalt-ag.

Open the catalog to page 7All Kalt Cheese Technology catalogs and technical brochures

-

Kalt Company

5 Pages

-

Cheese Vats

5 Pages