Website:

KALEJA GmbH

Website:

KALEJA GmbH

Catalog excerpts

Design for output currents up to 5 A Control with the following functions: - reversal of direction of rotation - open-loop speed control (external) - current limitation control (external) - overcurrent limitation / overcurrent shutdown - adjustable start ramp (external) - adjustable current monitoring delay - IxR compensation - short circuit detection - dynamic brake To snap onto the DIN rail EN 50022 Unit width: 22,5 mm C€ Article number | Operating data 26.11.2018 KL - Errors and technical modification subject to change. All rights reserved. KALEJA GmbH Strubelweg 14 D-73553 Alfdorf, Germany Phone: +49 7172 93711 0 info@kaleja.com

Open the catalog to page 1

Housing, terminals, printed circuit board _UL94V-0 After applying supply voltage, the module M3-4Q-5-30 is ready for operation when the start up time has elapsed. The M3-4Q-5-30 module is a multi-functional motor controller for use in industrial environments. It ensures the switching on and off, as well as the controlled driving of motors. The motor's direction of rotation can be set via a digital input. An internal trimmer can be used to set the maximum speed. By means of an analog input the speed can be set between 0 to maximum speed. The dynamic brake can be deactivated over a digital...

Open the catalog to page 2

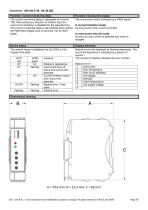

Datasheet M3-4Q-5-30 06.34.002 Typical application: Standard 26.11.2018 KL - Errors and technical modification subject to change. All rights reserved. © KALEJA GmbH

Open the catalog to page 3

The maximum output speed can be set or limited with the trimmer TR4. The speed setting itself is given through the analog input voltage at terminal (6) in the range of 0 to 100% adjustable via trimmer TR4. An analog voltage must be applied at terminal (6) in order to turn the motor. 0 V at terminal (6) equals to 0 rpm. If the module should operate only with the internal set speed, terminal (6) must be connected to + 10V / VCC, e.g. connect terminal (6) to terminal (7). If applying a HIGH signal at terminal (12), the motor output will be directly set to 100% PWM (speed). Regardless of any...

Open the catalog to page 4

| Function: dynamic brake The module stops the motor with “dynamic brake” function by default. It can be deactivated by applying a HIGH signal at terminal (11). If dynamic braking is active, the motor winding is switched to GND at both terminals when switched off. The motor is stopped with armature short circuit braking. If dynamic braking is not active, the motor stops with no braking. If both rotation direction inputs (terminals 1 and 2) are simultaneously high, the motor always stops with a dynamic brake. In this case the brake setting at the digital input (11). | Function: short circuit...

Open the catalog to page 5

| Function: current monitoring delay The current monitoring delay is adjustable by trimmer TR2. After setting any direction of rotation input the overcurrent shutdown is disabled for the adjusted time. The current monitoring delay is also started when setting the PWM100% digital input on terminal (12) to HIGH signal. | Function: Overcurrent output The overcurrent output indicates by a HIGH signal: In current limitation mode: As long as the motor current is limited. In overcurrent shut-off mode As soon as over current is detected and motor is stopped. Display elements The module status is...

Open the catalog to page 6

Maximum operational data The maximum operating data must not be exceeded. Installation The installation and start-up must be performed by specialist personnel exclusively. All affected components must be disconnected from the mains. Start-up For the first start-up, the motor should be operated without load. Risk of death Do not touch live parts after switching on! The assembly must be operated exclusively on safety extra-low voltage. With operation on extra-low voltage (e.g. via autotransformer), death or injury can occur. Fire protection The assembly must be installed in a switch cabinet,...

Open the catalog to page 7All KALEJA GmbH catalogs and technical brochures

-

M5-2QB-12-48 06.38.007

9 Pages

-

M5-BL-12-48 06.38.001

9 Pages

-

M-MWS-6-30

1 Pages

-

M-MRI-3-30

2 Pages

-

M-BL-5-30

2 Pages

-

M-MZ-4-30

2 Pages

-

Maxi-1Q-4-30

2 Pages

-

M-1Q-6-30

2 Pages

-

M-4Q-6-30

2 Pages

-

M-2Q-6-30

2 Pages

-

MAXI-GMF-8-30

4 Pages

-

M-S-6-30

2 Pages

-

Maxi-S-4-30

2 Pages

-

MAXI-MW-8-30

4 Pages

-

M2-CMR-5-30 06.34.018

6 Pages

-

Mini-SO-50-30

1 Pages

-

Mini-OM-50-30

1 Pages

-

Mini-OM-08-30

1 Pages

-

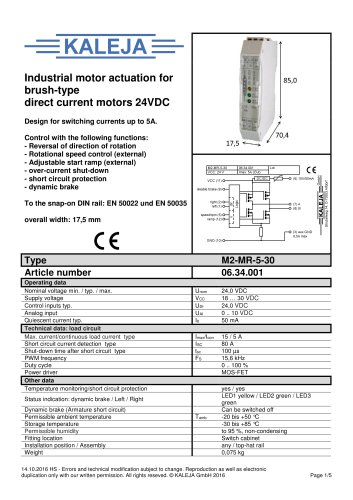

M2-MR-5-30

6 Pages

-

02.01.115_Mini-OM-25-30

1 Pages

-

06.04.202

4 Pages

-

06.04.201_Maxi-M-8-30

4 Pages

-

M2-3DR-5-30

8 Pages

-

M2-MWS-6-30

7 Pages

-

M2-MWI-6-30

7 Pages

-

M3-2QB-5-12

7 Pages

-

Maxi-IMD-5-60

3 Pages

-

Maxi-IM-5-60

3 Pages

-

MB-12

1 Pages

-

Midi-OM-100-30

1 Pages

-

USV-S-9-B

1 Pages

-

USV-S-25-S

1 Pages

-

M3-2QB-5-30

7 Pages

-

M2-MWT-6-30

7 Pages

-

06.34.008

2 Pages

-

06.04.032

2 Pages

-

06.34.006

7 Pages

-

06.34.002

6 Pages

-

01.01.212

1 Pages

-

01.01.213

1 Pages

-

02.01.104

1 Pages

-

02.01.116

1 Pages

-

02.01.117

1 Pages

-

02.01.130

1 Pages

-

02.03.226

1 Pages

-

02.06.201

1 Pages

-

04.08.001

1 Pages

-

06.04.007

2 Pages

-

06.04.008

2 Pages

-

06.04.012

1 Pages

-

06.04.014

1 Pages

-

06.04.016

2 Pages

-

06.04.019

2 Pages

-

06.04.021

2 Pages

-

06.04.025

2 Pages

-

06.04.031

2 Pages

-

06.04.039

2 Pages

-

06.04.046

2 Pages

-

06.04.048

2 Pages

-

06.04.049

2 Pages

-

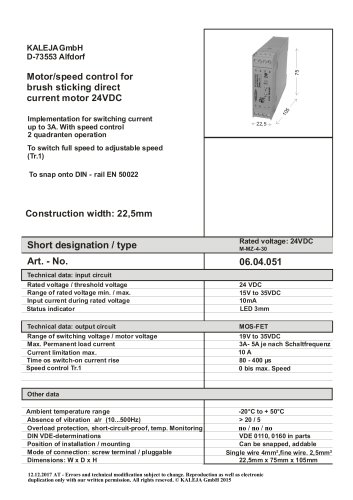

06.04.051

2 Pages

-

06.04.054

2 Pages

-

06.04.056

2 Pages

-

06.04.059

2 Pages

-

06.04.066

2 Pages

-

06.04.075

2 Pages

-

06.04.078

1 Pages

-

06.04.083

2 Pages

-

06.04.085

2 Pages

-

06.04.093

2 Pages

-

06.34.001

5 Pages

-

01.01.012

1 Pages

-

01.01.011E

1 Pages

-

01.01.007

1 Pages