Catalog excerpts

Heat Recovery for Hot Air and Hot Water Applications

Open the catalog to page 1

Heat recovery Why recover heat? The question should in fact be: Why not recover heat? Amazingly, 100 percent of the (electrical) energy input to a compressor is converted into heat. Up to 96 % of this energy can be recovered and reused for space heating or hot water production purposes. This not only reduces primary energy consumption, but also significantly improves the total energy balance. Saves money and benefits the environment For plate heat exchanger systems Compressor model Rated power Heat recovery Annual savings potential with fuel oil Heat in the compressor Amazingly, almost 100...

Open the catalog to page 2

Heat recovery Minimise primary energy consumption for heating The enclosed, compact design of modern rotary screw compressors makes them especially suitable for heat recovery. Direct use of the recyclable heat via a ducting system enables up to 96 % of the compressor’s total energy requirement to be recovered and used for heating purposes. This is the case irrespective of whether fluid-injection cooled compressors or dry-running screw compressors are used. energy reusable for heating purposes Heat recovery a win Amazingly, 100 percent of the electrical drive energy input to a compressor is...

Open the catalog to page 3

Heat recovery Minimise primary energy consumption for warming process, heating and service water Using recyclable heat from the compressor, heat exchanger systems can provide on-demand heating and service water warmed to temperatures up to 70°C, or even 90°C, depending on requirement. Conventional warming of heating and service water using recyclable heat is performed by PTG plate heat exchanger systems. Special fail-safe heat exchangers are recommended for applications that have no other interconnecting water circuits and where it is essential that the water being warmed remains...

Open the catalog to page 4

Equipment Hot air heat recovery PTG plate heat exchanger Tube-type heat exchanger All KAESER rotary screw compressors can be fitted with exhaust ducting. The ducting is installed on-site. Neighbouring rooms and warehouse space, for example, can be heated with the warmed cooling air. Rotary screw compressors from the SM series (from 5.5 kW) upwards can be equipped with PTG systems. Depending on the available water quality, either integrated plate or tube-type heat exchangers can be used in watercooled systems. Our compressed air specialists can advise you regarding which design is right for...

Open the catalog to page 5

Technical specifications Erdgas Heating cost Natural gas Heizkostensaving Einsparung €/Year m³ €/Jahr HeizkostenHeating cost Einsparung saving €/Jahr €/Year CSDX 140 CSDX 140 CSDX 165 CSDX 165 DSDX 243 DSDX 243 DSDX 302 DSDX 302 Calculation example for ASD 35 For natural gas Maximum available heat capacity: 20.2 kW Fuel value per litre of fuel oil: 9.861 kWh/l Fuel oil heating efficiency: 0.9 Price per litre of fuel oil: 0.70 €/l 1 kW = 1 MJ/h x 3.6 Maximum available heat capacity: 20.2 kW Fuel value per m³ natural gas: 10.2 kWh/m³ Natural gas heating efficiency: 1.05 Price per m³ of...

Open the catalog to page 6

As one of the world’s largest manufacturers of rotary screw compressors, KAESER KOMPRESSOREN is represented throughout the world by a comprehensive network of branches, subsidiary companies and authorised partners in over 100 countries. With innovative products and services, KAESER KOMPRESSOREN’s experienced consultants and engineers help customers to enhance their competitive edge by working in close partnership to develop progressive system concepts that continuously push the boundaries of performance and compressed air efficiency. Moreover, the decades of knowledge and expertise from...

Open the catalog to page 7All Kaeser Compressors catalogs and technical brochures

-

Compressed Air Filters

8 Pages

-

Automatic Magnetic Drain

2 Pages

-

Air Treatment Solutions

12 Pages

-

Activated Carbon Tower

2 Pages

-

SmartPipe+TM

28 Pages

-

S Series

8 Pages

-

SX - HSD Series

20 Pages

-

ASD, BSD, and CSD Series

12 Pages

-

KRYOSEC SERIES

4 Pages

-

Portable Compressors

8 Pages

-

Screw Compressor

20 Pages

-

Air Treatment Brochure

12 Pages

-

USGLANCE

6 Pages

-

Mobilair ? M350

2 Pages

-

CLEAN AIR

12 Pages

-

Mobilair M250

2 Pages

-

MobilairM27

2 Pages

-

SigmaControl2

6 Pages

-

Mobilair M122

2 Pages

-

Mobilair M100

2 Pages

-

Mobilair M64

2 Pages

-

Mobilair M57 Utility

2 Pages

-

Mobilair M57

2 Pages

-

Mobilair M50

2 Pages

-

Mobilair M15/M17

2 Pages

-

Mobilair Brochure

6 Pages

-

Hybritec Combination Dryer

8 Pages

Archived catalogs

-

Rotary Screw Vacuum Packages

4 Pages

-

Mobilair Tools

4 Pages

-

Mobilair M270

2 Pages

-

Mobilair M200

2 Pages

-

Mobilair M26

2 Pages

-

Booster Compressors

6 Pages

-

Airbox and Airbox Center

4 Pages

-

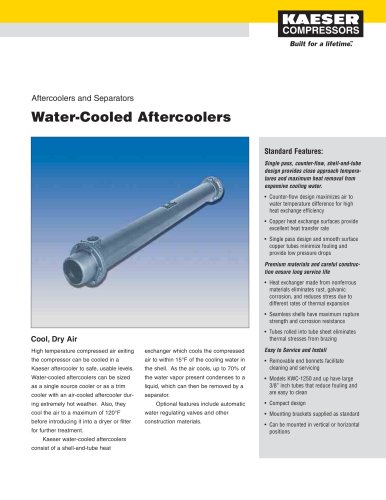

Water-cooled Aftercoolers

2 Pages

-

Air Cooled Aftercoolers

4 Pages

-

Air Main Charging System

4 Pages

-

Condensate Filters

4 Pages

-

Eco-Drain Traps

2 Pages

-

Automatic Magnetic Drain

2 Pages

-

High Temperature Afterfilter

2 Pages

-

Oil Mist Eliminator

2 Pages

-

Compressed Air Filters

8 Pages

-

Activated Carbon Tower

2 Pages

-

Membrane Dryers

2 Pages

-

Breathing Air Systems

4 Pages

-

Desiccant Air Dryers

12 Pages

-

Clean Air Treatment Brochure

4 Pages

-

SmartPipe Modular Piping Catalog

72 Pages

-

SmartPipe Modular Piping

72 Pages

-

HSD Series Compressors

8 Pages

-

ESD and FSD Compressors

6 Pages

-

DSD Series Compressors

6 Pages

-

CSD Series Compressors

6 Pages

-

BSD Series Compressors

6 Pages

-

ASD Series Compressors

6 Pages

-

AS Series Compressors

6 Pages

-

SK Series Compressors

6 Pages

-

SM Series Compressors

6 Pages

-

SX Series Compressors

6 Pages

-

AirCenter

4 Pages