Catalog excerpts

Kaeser Gives You the Air Quality You Require Ambient air contains contaminants that are drawn into the compressor. These contaminants are concentrated during compression and find their way into the compressed air system. A typical compressed air system is contaminated with abrasive solid particles such as dirt, rust and pipe scale, compressor lubricants, condensed water droplets, and oil and hydrocarbon vapors. Contaminated compressed air systems increase operating costs by robbing the air system of useful power. This results in reduced efficiency, damaged airoperated equipment, higher...

Open the catalog to page 2

Standard Features and Benefits Modular Housings for Flows up to 780 scfm • Manufactured from top quality aluminum and steel • Epoxy powder coated (interior and exterior) for added durability and corrosion resistance • All filter types fit same size housings • 1/8 turn bayonet head to bowl connections for easy access (20 to 170 scfm) • Threaded connection for 250 scfm and up • Optimized air flow through housing minimizes pressure drop • The tapered housing and non-turbulent lower filter zone prevents condensate from being picked up by the air flow • Audible warning if disassembly attempted...

Open the catalog to page 3

Premium Options Filter Monitor • Microprocessor control and LCD display • Indicates optimum element replacement based on: - operating time - differential pressure - filter type • Filter replacement “warning” • Continuously measures differential pressure Filter Connection Set Quickly isolates condensate drain for easy maintenance without interrupting air supply. Eco-Drain • Non-wearing electronic probe does not have moving parts • Reliably discharges condensate, but not costly compressed air • Self-checking electronics with automatic alarm test button, and voltage free alarm contact • LEDs...

Open the catalog to page 4

Filter Accessories Other Clean Air Treatment Products Oil Mist Eliminators (OME) Oil Mist Eliminators (OME) are large oil removal filters with a very low pressure drop. Not only do they remove both oil aerosols and water, but they can handle large slugs of liquid. The cartridge life is normally 8 to 15 years, requiring virtually no maintenance. Sizes: 125 – 3000 scfm High Pressure Filters (HP) High Pressure filters (HP) are available for applications requiring pressures up to 900 psig. They include seam welded stainless steel cores for greater durability and corrosion resistance. Condensate...

Open the catalog to page 5

Note 1: All Kaeser Rotary Screw Compressors have built-in aftercoolers. However, for equipment without an aftercooler or where the discharge temperature is 110°F or higher, an aftercooler should be positioned at the location shown. KFS/KPF/KOR/KOX filter elements should be replaced at 10 psid (red area of Delta P gauge) or annually, whichever occurs first. KVF filter elements should be replaced after 1,000 hours of operation or annually, whichever occurs first. Kaeser recommends processing condensate through the KCF which safely and economically disposes of the environmentally threatening...

Open the catalog to page 6

Specifications *Standard Features of Filters 1 - Manual Drain, Liquid Level Indicator (Automatic drain trap is STRONGLY recommended) 2 - Manual Drain (Automatic drain trap is STRONGLY recommended) 3 - Plugged Drain Port (Automatic drain trap is STRONGLY recommended) 4 - Internal Automatic Drain, Delta P Slide Indicator, Liquid Level Indicator 5 - Internal Automatic Drain, Delta P Gauge, Liquid Level Indicator 6 - Manual Drain, Delta P Gauge, Liquid Level Indicator (Automatic drain trap is STRONGLY recommended) 7 - Manual Drain, Delta P Gauge (Automatic drain trap is STRONGLY recommended) 8...

Open the catalog to page 7

Kaeser’s U.S. Headquarters in Fredericksburg, Virginia The Air Systems Specialist With over 85 years of experience, Kaeser is the air systems specialist. Our extensive 100,000 square foot facility allows us to provide unequaled product availability. With service centers nationwide and our 24-hour emergency parts guarantee, Kaeser customers can rely on the best after-sales support in the industry. Kaeser stands committed to providing the highest quality air system for your specific compressed air needs. Mission Statement We strive to earn our customers’ trust by supplying high quality Kaeser...

Open the catalog to page 8All Kaeser Compressors catalogs and technical brochures

-

Compressed Air Filters

8 Pages

-

Automatic Magnetic Drain

2 Pages

-

Air Treatment Solutions

12 Pages

-

Activated Carbon Tower

2 Pages

-

SmartPipe+TM

28 Pages

-

S Series

8 Pages

-

SX - HSD Series

20 Pages

-

ASD, BSD, and CSD Series

12 Pages

-

KRYOSEC SERIES

4 Pages

-

Portable Compressors

8 Pages

-

Screw Compressor

20 Pages

-

Air Treatment Brochure

12 Pages

-

USGLANCE

6 Pages

-

Mobilair ? M350

2 Pages

-

CLEAN AIR

12 Pages

-

Mobilair M250

2 Pages

-

MobilairM27

2 Pages

-

SigmaControl2

6 Pages

-

Mobilair M122

2 Pages

-

Mobilair M100

2 Pages

-

Mobilair M64

2 Pages

-

Mobilair M57 Utility

2 Pages

-

Mobilair M57

2 Pages

-

Mobilair M50

2 Pages

-

Mobilair M15/M17

2 Pages

-

Mobilair Brochure

6 Pages

-

Hybritec Combination Dryer

8 Pages

Archived catalogs

-

Rotary Screw Vacuum Packages

4 Pages

-

Mobilair Tools

4 Pages

-

Mobilair M270

2 Pages

-

Mobilair M200

2 Pages

-

Mobilair M26

2 Pages

-

Booster Compressors

6 Pages

-

Airbox and Airbox Center

4 Pages

-

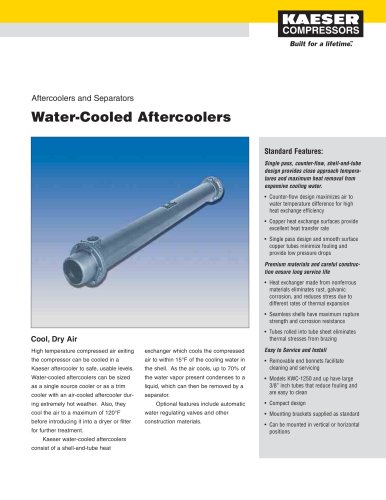

Water-cooled Aftercoolers

2 Pages

-

Air Cooled Aftercoolers

4 Pages

-

Air Main Charging System

4 Pages

-

Condensate Filters

4 Pages

-

Eco-Drain Traps

2 Pages

-

Automatic Magnetic Drain

2 Pages

-

High Temperature Afterfilter

2 Pages

-

Oil Mist Eliminator

2 Pages

-

Activated Carbon Tower

2 Pages

-

Membrane Dryers

2 Pages

-

Breathing Air Systems

4 Pages

-

Desiccant Air Dryers

12 Pages

-

Clean Air Treatment Brochure

4 Pages

-

SmartPipe Modular Piping Catalog

72 Pages

-

SmartPipe Modular Piping

72 Pages

-

HSD Series Compressors

8 Pages

-

ESD and FSD Compressors

6 Pages

-

DSD Series Compressors

6 Pages

-

CSD Series Compressors

6 Pages

-

BSD Series Compressors

6 Pages

-

ASD Series Compressors

6 Pages

-

AS Series Compressors

6 Pages

-

SK Series Compressors

6 Pages

-

SM Series Compressors

6 Pages

-

SX Series Compressors

6 Pages

-

AirCenter

4 Pages