Catalog excerpts

Compressed Air Treatment Guide Meeting Your Compressed Air Treatment Needs How to Select the Right Equipment for Your Application Provided as a Service by Kaeser Compressors, Inc.

Open the catalog to page 1

2 Visit our Website: www.kaeser.com Meeting Your Compressed Air Treatment Needs Why do we need compressed air treatment? Because ambient air contains contaminants that are drawn into the compressor. These contaminants are compressed and intensified and find their way into the compressed air system. Contaminants are also introduced into the compressed air stream by the compressor, receiver tank, piping, and other installed components. There are three different forms in which contaminants exist: •• Solids - dirt, dust, pipe scale, compressor wear particles • Liquids/Aerosols - oil and water •...

Open the catalog to page 2

Kaeser Compressed Air Treatment Guide 3 Dryers Don’t dilute the performance of your compressed air system The heart of the system The heart of any compressed air system is the air compressor itself. When selecting an air compressor, the most important factors to consider are quality and reliability. Reflected in quality and reliability are overall cost, efficiency, and easy maintenance. The most cost-effective unit is rarely the lowest priced. Components to evaluate in a compressor include: • Airend: look at the package efficiency and check with the manufacturer for CAGI data sheets....

Open the catalog to page 3

4 Visit our Website: www.kaeser.com Channeling, when an air stream finds a path through the bed and follows the path instead of flowing evenly throughout the bed, is often a problem with desiccant dryers. Channeling can be avoided by using stainless steel diffusers in the inlet and outlet of the desiccant towers and controlling air velocity through the desiccant bed. Desiccant dryers are either cold regenerative or heat regenerative. In cold regenerative dryers, 15% of dried compressed air is diverted from the air outlet and is used to purge the wet desiccant bed. In heat regenerative...

Open the catalog to page 4

Kaeser Compressed Air Treatment Guide 5 What Size Contaminants are Found in a Compressed Air System? If .01 micron is this big And 1 micron could not fit on this page! Measured in microns (ìm) 1 millionth of a meter or 0.000039 inches Human Hair (section): 30 to 200 ìm Visible to eye: 50 ìm Water aerosols: 1 to 20 ìm Bacteria: 0.25 to 20 ìm Oil and oil aerosols: 0.01 to 5 ìm Solid particles: 0.5 to 5 ìm Tobacco smoke: 0.01 to 1.0 ìm Viruses: 0.003 to 0.05 ìm Then .1 micron is this big Filters Protect System Components and Maintain Product Quality Compressed air systems contain contaminants...

Open the catalog to page 5

6 Visit our Website: www.kaeser.com The Kaeser Filtered Centrifugal Separator uses centrifugal separation and mechanical filtration to remove bulk liquids from a compressed air system. Available in models from 20 scfm to 21,250 scfm, the Kaeser Particulate Filter removes liquid aerosols, rust, scale, dirt, and other solid particles one micron and larger. Used within its rated design conditions, the coalescing Kaeser Oil Removal Filter eliminates the oil aerosols contained in a compressed air system. Its unique, continuously stabilized filter medium plus outer foam sleeve ensure 99.999+%...

Open the catalog to page 6

Kaeser Compressed Air Treatment Guide 7 Drain Traps and Aftercoolers Drain Traps reduce plant operating costs, lower maintenance, and prevent air lines from flooding. They eliminate bleeding expensive compressed air through pet-cocks or manually draining compressed air lines and equipment. A ball valve should precede all drain traps to facilitate routine maintenance without interruption. Demand-Operated Drain Traps automatically discharge moisture and oil-containing condensate from the system. Drain traps should discharge only liquids, not costly compressed air, and do not require a...

Open the catalog to page 7

© 2008 Kaeser Compressors, Inc. All rights reserved. 04/08 USGUIDE2 Corporate Headquarters: Kaeser Compressors, Inc. P.O. Box 946 Fredericksburg, VA 22404 (800) 777-7873 Fax: (540) 898-5520 www.kaeser.com Mission Statement We strive to earn our customers’ trust by supplying high quality Kaeser air compressors, related compressed air equipment and premium blower systems. Our products are designed for reliable performance, easy maintenance, and energy efficiency. Prompt and dependable customer service, quality assurance, training, and engineering support contribute to the value our customers...

Open the catalog to page 8All Kaeser Compressors catalogs and technical brochures

-

Compressed Air Filters

8 Pages

-

Automatic Magnetic Drain

2 Pages

-

Air Treatment Solutions

12 Pages

-

Activated Carbon Tower

2 Pages

-

SmartPipe+TM

28 Pages

-

S Series

8 Pages

-

SX - HSD Series

20 Pages

-

ASD, BSD, and CSD Series

12 Pages

-

KRYOSEC SERIES

4 Pages

-

Portable Compressors

8 Pages

-

Screw Compressor

20 Pages

-

Air Treatment Brochure

12 Pages

-

USGLANCE

6 Pages

-

Mobilair ? M350

2 Pages

-

CLEAN AIR

12 Pages

-

Mobilair M250

2 Pages

-

MobilairM27

2 Pages

-

SigmaControl2

6 Pages

-

Mobilair M122

2 Pages

-

Mobilair M100

2 Pages

-

Mobilair M64

2 Pages

-

Mobilair M57 Utility

2 Pages

-

Mobilair M57

2 Pages

-

Mobilair M50

2 Pages

-

Mobilair M15/M17

2 Pages

-

Mobilair Brochure

6 Pages

-

Hybritec Combination Dryer

8 Pages

Archived catalogs

-

Rotary Screw Vacuum Packages

4 Pages

-

Mobilair Tools

4 Pages

-

Mobilair M270

2 Pages

-

Mobilair M200

2 Pages

-

Mobilair M26

2 Pages

-

Booster Compressors

6 Pages

-

Airbox and Airbox Center

4 Pages

-

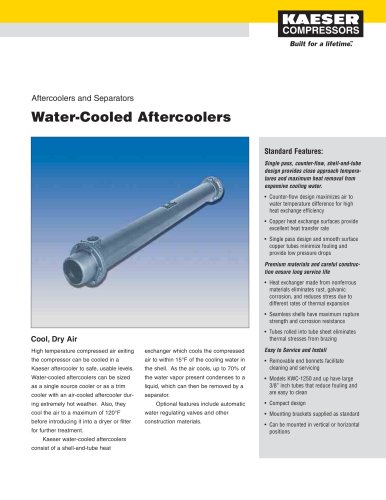

Water-cooled Aftercoolers

2 Pages

-

Air Cooled Aftercoolers

4 Pages

-

Air Main Charging System

4 Pages

-

Condensate Filters

4 Pages

-

Eco-Drain Traps

2 Pages

-

Automatic Magnetic Drain

2 Pages

-

High Temperature Afterfilter

2 Pages

-

Oil Mist Eliminator

2 Pages

-

Compressed Air Filters

8 Pages

-

Activated Carbon Tower

2 Pages

-

Membrane Dryers

2 Pages

-

Breathing Air Systems

4 Pages

-

Desiccant Air Dryers

12 Pages

-

Clean Air Treatment Brochure

4 Pages

-

SmartPipe Modular Piping Catalog

72 Pages

-

SmartPipe Modular Piping

72 Pages

-

HSD Series Compressors

8 Pages

-

ESD and FSD Compressors

6 Pages

-

DSD Series Compressors

6 Pages

-

CSD Series Compressors

6 Pages

-

BSD Series Compressors

6 Pages

-

ASD Series Compressors

6 Pages

-

AS Series Compressors

6 Pages

-

SK Series Compressors

6 Pages

-

SM Series Compressors

6 Pages

-

SX Series Compressors

6 Pages

-

AirCenter

4 Pages