Catalog excerpts

Air Compressor Guide Compressor Maintenance Compressed Air Dryer Maintenance System Accessory Maintenance Reference Library A Guide to Cost Savings with Air System Maintenance System Pressure: 100 psig Maintenance Complete

Open the catalog to page 1

Preventive maintenance is the solution to keeping your compressed air system in top condition. While the life cycle of any industrial air compressor typically exceeds ten years, proper maintenance is crucial to maintain performance and efficiency. Compressors can be divided into seven sub-assemblies; Pump or Airend, Motor, Drive Train, Lubricants, Controllers, Coolers, and Filters. Because these sub-assemblies are expensive components, they need to be maintained on a regular basis. In addition, the benefits of using genuine filters and maintenance parts and replacing them when needed should...

Open the catalog to page 2

Filter Airend Lubricant Maintenance Indicators Filter Motor Drive Coupling Coolers Pump or Airend Piston/Pump .. Check the inlet and discharge valves for sticking due to carbon deposits. .. Check for excessive air through the crank case breather indicating worn piston rings. .. Check for low oil pressure indicating worn bearings. Recommended Rebuild: 5,000-10,000 Hours Rotary Screw Airend .. Check for mechanical seal leakage. .. Check for inlet valve wear. .. Check for excessive bearing “play”. Recommended Rebuild: 50,000-100,000 Hours Motor .. Grease motor bearings with the right type of...

Open the catalog to page 3

Hot compressed air contains large amounts of water vapor. When traveling downstream, the water vapor condenses into liquid and causes corrosion in piping, components, air tools and production equipment. Compressed air dryers remove harmful moisture and are an indispensible part of any clean air treatment process. Refrigerated Dryers Refrigerated dryers are very reliable and the most commonly used dryer type. They remove water from compressed air by cooling it so that the water vapor condenses and is separated. A refrigerated dryer consists of heat exchangers, refrigeration compressor,...

Open the catalog to page 4

Refrigerated Dryers Condenser Unit Clogged condensers account for most dryer problems. .. Periodically clean the fins with compressed air or a bristle brush to ensure enough refrigerant is transformed into a liquid state, for proper heat removal in the evaporator. Do not bend or damage the fins of the heat exchanger during cleaning. Separator/Drain The most critical area for dryer performance is proper drain function at the separator. Separated water needs to be discharged from the system frequently to avoid reentrance into the air system. .. Check separator and drain function regularly by...

Open the catalog to page 5

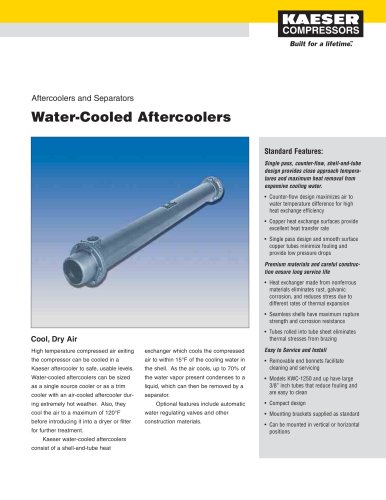

Aftercoolers reduce the air temperature caused by the compression process close to ambient levels, where the air can be treated further. Aftercoolers are either air or water-cooled and eliminate up to 80% of all water vapor. Filters Filter technology has steadily advanced to provide reliable removal of solid particles, oil aerosols, water, and hydrocarbon vapors. It is possible to produce air thousands of times cleaner than the air we breathe. When selecting filters, ensure that the liquid loading (amount of water or oil) as well as the solid particle size does not exceed the filter rating....

Open the catalog to page 6

Kaeser Air Compressor Guide 7 Air-cooled Aftercoolers .. Clean heat exchanger fins with compressed air or a bristle brush. Be careful not to damage or bend fins. Water-cooled Aftercoolers .. Check for proper water pressure and inlet/outlet temperatures. .. Check heat exchanger on water and air side for fouling. Mineral deposits on water side negatively influence heat transfer. Clean or flush with special cleaning solvent if necessary. Moisture Separator with Drain .. Check separator filter element for pressure drop. .. Check drain for proper function. Rebuild mechanism if necessary. .....

Open the catalog to page 7

8 Visit our Website: www.kaeser.com Kaeser Compressors, Inc. has been in business for more than 85 years providing quality compressed air products to a worldwide market. Its development of the high efficiency Sigma Profile for rotary screw compressors marked a major technological advance in compressor design. Kaeser also manufacturers blowers, vacuum systems, portable air compressors, as well as reciprocating compressors, booster compressors, and oil-less compressors featuring the same high-quality standards as their screw compressors. For clean air treatment, Kaeser offers a complete line...

Open the catalog to page 8All Kaeser Compressors catalogs and technical brochures

-

Compressed Air Filters

8 Pages

-

Automatic Magnetic Drain

2 Pages

-

Air Treatment Solutions

12 Pages

-

Activated Carbon Tower

2 Pages

-

SmartPipe+TM

28 Pages

-

S Series

8 Pages

-

SX - HSD Series

20 Pages

-

ASD, BSD, and CSD Series

12 Pages

-

KRYOSEC SERIES

4 Pages

-

Portable Compressors

8 Pages

-

Screw Compressor

20 Pages

-

Air Treatment Brochure

12 Pages

-

USGLANCE

6 Pages

-

Mobilair ? M350

2 Pages

-

CLEAN AIR

12 Pages

-

Mobilair M250

2 Pages

-

MobilairM27

2 Pages

-

SigmaControl2

6 Pages

-

Mobilair M122

2 Pages

-

Mobilair M100

2 Pages

-

Mobilair M64

2 Pages

-

Mobilair M57 Utility

2 Pages

-

Mobilair M57

2 Pages

-

Mobilair M50

2 Pages

-

Mobilair M15/M17

2 Pages

-

Mobilair Brochure

6 Pages

-

Hybritec Combination Dryer

8 Pages

Archived catalogs

-

Rotary Screw Vacuum Packages

4 Pages

-

Mobilair Tools

4 Pages

-

Mobilair M270

2 Pages

-

Mobilair M200

2 Pages

-

Mobilair M26

2 Pages

-

Booster Compressors

6 Pages

-

Airbox and Airbox Center

4 Pages

-

Water-cooled Aftercoolers

2 Pages

-

Air Cooled Aftercoolers

4 Pages

-

Air Main Charging System

4 Pages

-

Condensate Filters

4 Pages

-

Eco-Drain Traps

2 Pages

-

Automatic Magnetic Drain

2 Pages

-

High Temperature Afterfilter

2 Pages

-

Oil Mist Eliminator

2 Pages

-

Compressed Air Filters

8 Pages

-

Activated Carbon Tower

2 Pages

-

Membrane Dryers

2 Pages

-

Breathing Air Systems

4 Pages

-

Desiccant Air Dryers

12 Pages

-

Clean Air Treatment Brochure

4 Pages

-

SmartPipe Modular Piping Catalog

72 Pages

-

SmartPipe Modular Piping

72 Pages

-

HSD Series Compressors

8 Pages

-

ESD and FSD Compressors

6 Pages

-

DSD Series Compressors

6 Pages

-

CSD Series Compressors

6 Pages

-

BSD Series Compressors

6 Pages

-

ASD Series Compressors

6 Pages

-

AS Series Compressors

6 Pages

-

SK Series Compressors

6 Pages

-

SM Series Compressors

6 Pages

-

SX Series Compressors

6 Pages

-

AirCenter

4 Pages