Catalog excerpts

Energy Management Services Air Demand Analysis

Open the catalog to page 1

Benefi ts of an Air Demand Analysis • Significantly reduce energy costs by identifying and eliminating inefficiencies in your system. • Reduce production scrap/waste by providing consistent pressure to production equipment. • Cut air compressor maintenance costs by optimizing run time and reducing excess cycling. • Reduce production equipment maintenance costs through improved air quality. • Minimize downtime by reducing maintenance intervals of compressors. • Reduce your carbon footprint with lower energy consumption. • Help qualify for utility rebate programs to pay for system upgrades....

Open the catalog to page 2

The Stakes are High Now more than ever, operational excellence is key to remaining competitive. Improving production rates, raising quality and minimizing resource costs are the drivers for competitive success. Your compressed air system impacts all three, and presents a great opportunity for improvement in your plant. But there are other important incentives to reduce energy consumption. From the consumers’ perspective, the industrial “carbon footprint” is a growing concern, so environmental stewardship is also a strategic issue. According to the latest estimates, optimizing existing...

Open the catalog to page 3

Your Kaeser fi eld representative will visit your site to: • Collect detailed information on your system components, environmental conditions, and physical layout. • Collect appropriate supporting graphical data such as photographs, schematic drawings and sketches. • Gather input on specific problems your plant is currently facing, and discuss desired outcomes. Site Survey/Walk-through The fi rst step in an Air Demand Analysis is to become thoroughly familiar with your air system. We review all components of your air system: • Compressors and their control type • Clean air treatment...

Open the catalog to page 4

Data Logging To obtain a detailed, accurate picture of your compressed air demand and system dynamics, we install a variety of instruments and sensors customized to your unique system. Our approach creates a complete picture of system activity – including leaks, which are often most apparent during offpeak production periods. Measurement devices may include: – Pressure sensors to measure pressure throughout the system. – Kilowatt meters to measure actual power consumption of compressor equipment. – Flowmeters to measure compressor flow and system demand. – Opto-couplers to monitor digital...

Open the catalog to page 5

Your Air Demand Analysis from Kaeser isn’t complete until we issue our fi nal report that outlines the results of our analysis and recommendations. This report includes a specifi c action plan you can use as a guide to implement recommendations on a timeline of your choosing. It outlines the recommended actions and their associated costs, as well as the projected energy cost savings. Your ADA fi nal report helps you prioritize optimization efforts based on Recommendations for Measurable, Achievable Results measurable fi nancial and operational benefi ts. Recommendations do not necessarily...

Open the catalog to page 6

Will my facility benefi t from a Kaeser Air Demand Analysis? • Have we calculated the energy costs associated with our air system? • Do we have a pressure/fl ow/energy profi le, so we know what is actually happening in our air system? • Do we know what our air demand is? • Have we ever measured pressure drop in our piping? • Have we ever tested for leaks? • Do we have secondary storage or controls separating air supply from distribution? • Do we have a stable supply of air at the required pressure at all points of use? • Have we eliminated high scrap rates or eliminated lower product...

Open the catalog to page 7

Kaeser’s U.S. Headquarters in Fredericksburg, Virginia The Air Systems Specialist With over 90 years of experience, Kaeser is the air systems specialist. Our extensive 120,000 square foot facility allows us to provide unequaled product availability. With service centers nationwide and our 24-hour emergency parts guarantee, Kaeser customers can rely on the best after-sales support in the industry. Kaeser stands committed to providing the highest quality air system for your specifi c compressed air needs. Mission Statement We strive to earn our customers’ trust by supplying high quality...

Open the catalog to page 8All Kaeser Compressors catalogs and technical brochures

-

Compressed Air Filters

8 Pages

-

Automatic Magnetic Drain

2 Pages

-

Air Treatment Solutions

12 Pages

-

Activated Carbon Tower

2 Pages

-

SmartPipe+TM

28 Pages

-

S Series

8 Pages

-

SX - HSD Series

20 Pages

-

ASD, BSD, and CSD Series

12 Pages

-

KRYOSEC SERIES

4 Pages

-

Portable Compressors

8 Pages

-

Screw Compressor

20 Pages

-

Air Treatment Brochure

12 Pages

-

USGLANCE

6 Pages

-

Mobilair ? M350

2 Pages

-

CLEAN AIR

12 Pages

-

Mobilair M250

2 Pages

-

MobilairM27

2 Pages

-

SigmaControl2

6 Pages

-

Mobilair M122

2 Pages

-

Mobilair M100

2 Pages

-

Mobilair M64

2 Pages

-

Mobilair M57 Utility

2 Pages

-

Mobilair M57

2 Pages

-

Mobilair M50

2 Pages

-

Mobilair M15/M17

2 Pages

-

Mobilair Brochure

6 Pages

-

Hybritec Combination Dryer

8 Pages

Archived catalogs

-

Rotary Screw Vacuum Packages

4 Pages

-

Mobilair Tools

4 Pages

-

Mobilair M270

2 Pages

-

Mobilair M200

2 Pages

-

Mobilair M26

2 Pages

-

Booster Compressors

6 Pages

-

Airbox and Airbox Center

4 Pages

-

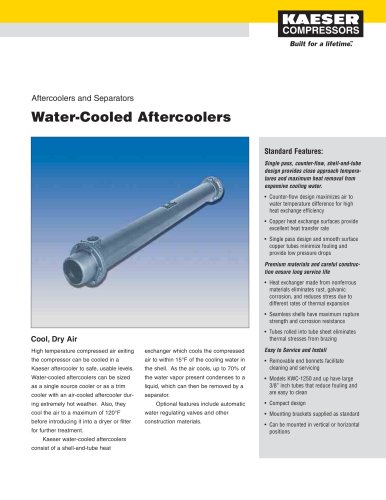

Water-cooled Aftercoolers

2 Pages

-

Air Cooled Aftercoolers

4 Pages

-

Air Main Charging System

4 Pages

-

Condensate Filters

4 Pages

-

Eco-Drain Traps

2 Pages

-

Automatic Magnetic Drain

2 Pages

-

High Temperature Afterfilter

2 Pages

-

Oil Mist Eliminator

2 Pages

-

Compressed Air Filters

8 Pages

-

Activated Carbon Tower

2 Pages

-

Membrane Dryers

2 Pages

-

Breathing Air Systems

4 Pages

-

Desiccant Air Dryers

12 Pages

-

Clean Air Treatment Brochure

4 Pages

-

SmartPipe Modular Piping Catalog

72 Pages

-

SmartPipe Modular Piping

72 Pages

-

HSD Series Compressors

8 Pages

-

ESD and FSD Compressors

6 Pages

-

DSD Series Compressors

6 Pages

-

CSD Series Compressors

6 Pages

-

BSD Series Compressors

6 Pages

-

ASD Series Compressors

6 Pages

-

AS Series Compressors

6 Pages

-

SK Series Compressors

6 Pages

-

SM Series Compressors

6 Pages

-

SX Series Compressors

6 Pages

-

AirCenter

4 Pages