Website:

JW FROEHLICH Maschinenbau GmbH

Website:

JW FROEHLICH Maschinenbau GmbH

Catalog excerpts

Leak Test Panel Series 300 Versatile and modularThe Satellite Panel The Series 300 highlights at a glance Basic features Single channel measuring system Pressure decay/increase method Relative or differential pressure Mass flow measurement Electronic pressure regulator 32 test programmes Data communication RS 232 and binary I/O interfaces Last 500 test results stored Last 100,000 test results stored using CALT software (PC) Statistical evaluation of test results Operation Easy operation using an intuitive menu structure LCD plain text display USB connection on the front The leak test panels in Series 300 are the ideal choice for integration into machine lines and production facilities. They make use of the decentralised master/slave principle and satellite technology. The measurement processes running reliably in the background can be visualised on a standard Windows 7 based PC or HMI.

Open the catalog to page 1

Technical data Options include Language settings Temperature compensation External control unit Q-DAS software High pressure up to 20 bar (MPS350) Ethernet interface Profibus/Profinet/Ethernet IP External measure circuit Special functions Volume-dependent leak test Auto-mastering function Auto-parameter module Back pressure test DAE (membrane test) CALT software (PC) Accessories Service package Leak calibrator LK 100/800 Calibrated leaks Vacuum pump Barcode scanner incl. software Factory calibration Mapping Training Parameterisation JWFROEHLICH Test and Assembly Solutions for Powertrain...

Open the catalog to page 2All JW FROEHLICH Maschinenbau GmbH catalogs and technical brochures

-

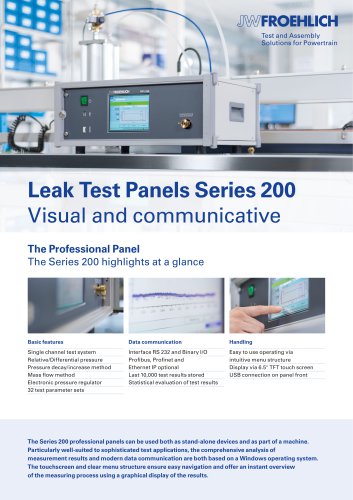

Leak Test Panels Series 200

2 Pages

-

Leak Test Panel Series 500

2 Pages

-

Device comparison

6 Pages

-

Leak calibrator

2 Pages

-

Leak test panels Series 400

2 Pages

-

Leak test panels Series 500

2 Pages

-

Leak test panels Series 200

2 Pages

-

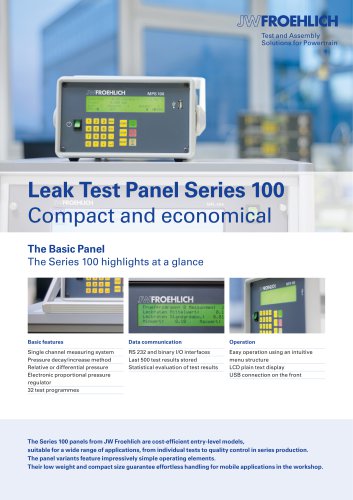

Leak test panels Series 100

2 Pages