Catalog excerpts

81 Packaged Sewage Disposal Units Application compli 400 The compli 400 is the smallest of our packaged sewage disposal units. It has been specifically designed for the disposal of sewage from single dwellings. For easy access and service it is installed on the ground of a basement or in an accessible sump. The ready to connect control unit is pre-wired with the pump and the level control. An additional inlet is available for other waste water discharge points such as shower, washing machine or sink. The compli 400 consists of long lasting materials: rust-proof steel for the shaft and polyethylene for the 50-l-tank. compli 500 The compli 500 has been designed specifically for the disposal of sewage from single dwellings with continued sewage water inlet and for a larger tank volume. It is also extremely easy to handle and installation requires a minimum of space. The PE-tank has accessible pipe connections and a particularly simple „pinch“ type inlet flange for the connection of pipe or bend. As all units, the maintenance is extremly simple: the tank has a top mounted inspection opening and, if necessary, the pumping unit can be removed/ replaced in minutes and without disturbing the tank assembly. compli 1000 The compli 1000 is one of our series of duplex package sewage disposal units. It should be installed where additional security for sewage disposal is demanded. In certain cases the Local Authority will insist on duplicate systems also on public applications such as restaurants, leisure centers etc., duplex systems are always advised. The standard package is complete with integrated swing-type check valve, making the use of “Y” pieces on the discharge unnecessary. compli 600/1200 The compli 1200 is provided with a large tank and has specifically been designed for the disposal of sewage from flats and industrial plants where sewage flow is continuous. For ease of installation the unit is provided with variable height inlet 560 to 700 mm. The control unit is provided with mains dependent alarm and a volt-free contact for collective fault signal. The compli 600 has the same tank volume, but provided with a one-pump system. compli 400 compli 500 compli 1200 compli 1000 D 206-1.6E-0505 V

Open the catalog to page 1

82 Performance curves The minimum flow velocity in the pressure piping must be 0,7 m/s according to EN 12056. This data is represented in the performance curve as a limit of application. We reserve the right to change specifications without notice. Pump performance is subject to ISO 9906 tolerances.

Open the catalog to page 2

85 Accessories Code No. c 400 c 500 c 1000 c 600/1200 Seal leak control unit DKG (for 25/2 BW and 35/2 BW) 252 œ œ Rechargeable battery for off the 7562 œ œ œ œ line operation of the alarm system PVC sluice valve (two pipe sockets) for inlet 4“ 28297 œ œ œ (DN 100), PN 2,5 PVC sluice valve (two pipe sockets) for inlet 6“ 28591 œ (DN 150), PN 2,5 Sluice valve* for discharge pipe 3“ DN 80, 639 œ œ œ œ PN 10, EN 1171 H L E D 360 295 060 110 for inlet 4“ 660 450 110 160 for inlet 6“ 315 180 – DN 80 for discharge pipe 3“ Swing-type check valve * R 80, PN 4, flange PN 10 706 œ œ without...

Open the catalog to page 5

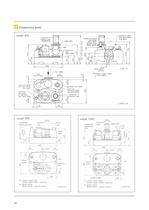

86 Dimensions (mm) compli 400 compli 500 compli 1000

Open the catalog to page 6

87 All units are supplied with a discharge flange n.b. 80/PN 10 but with spigot flange DN 100. If the swing-type check valve is to be mounted directly on the unit it must have a dimension of 80 mm n.b. The discharge pipe can then be connected with the 100 mm elastic connection. compli 600/1200 For your safety we recommend: • 60 cm working area above and around all parts that have to be operated • an additional pump sump for the drainage of the operational room • a swing-type check valve at the outlet • a stop valve at the outlet • a stop valve at the inlet • a bouyancy-proof installation

Open the catalog to page 7

88 Technical data Pump Vertical, single-stage, submersible, vortex impeller, spiral casing with vertical discharge DN 100, flanged to PE-tank with top mounted cleaning operture, compli 1000 and compli 600/1200 with opening duplex swing-type check valve. Bearing Common shaft for pump and motor, greased ball bearings. Seal compli 400 two radial lip seals. 10/4-25/4 BW duplex rotary shaft seal, 25/2 BW and 35/2 BW silicon carbide mechanical seals (independent of rotation and safe to run dry). Oil chamber with duplex rotary shaft seal towards the motor section. A seal leak control can be...

Open the catalog to page 8All JUNG PUMPEN catalogs and technical brochures

-

Simer 5

2 Pages

-

U2 KS

2 Pages

-

Lifting stations

5 Pages

-

WCfix plus

2 Pages

-

Plancofix / Plancofix plus

5 Pages

-

K2 plus

4 Pages

-

Hebefix plus/extra

2 Pages

-

Baufix 100

2 Pages

-

US pumps

4 Pages

-

Drainage set

2 Pages

-

oxylift & oxyperl

4 Pages

-

Hebefix plus

4 Pages

-

Condensate Pump K2

2 Pages

-

Flushing pipe

2 Pages

-

Guide rail adapter

4 Pages

-

Poly sump PKS-B

2 Pages

-

compli

6 Pages

-

compli 300 E

2 Pages

-

K2

2 Pages

-

U 6 K

2 Pages

-

U 3 K / U 5 K

2 Pages

Archived catalogs

-

2019 U3 / U5 / U6

4 Pages

-

Flutbox

4 Pages