Website:

JORDAN VALVE

Website:

JORDAN VALVE

Group: RICHARDS INDUSTRIES

Catalog excerpts

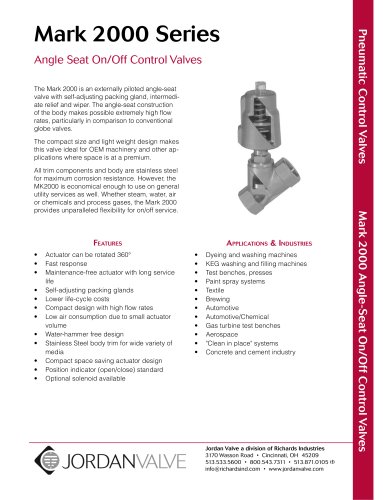

Jordan Valve a division of Richards Industries 3170 Wasson Road • Cincinnati, OH 45209 513.533.5600 • 800.543.7311 • 513.871.0105 (f) info@richardsind.com • www.jordanvalve.com Mark 2000 Series Angle Seat On/Off Control Valves The Mark 2000 is an externally piloted angle-seat valve with self-adjusting packing gland, intermediate relief and wiper. The angle-seat construction of the body makes possible extremely high flow rates, particularly in comparison to conventional globe valves. The compact size and light weight design makes this valve ideal for OEM machinery and other applications where space is at a premium. All trim components and body are stainless steel for maximum corrosion resistance. However, the MK2000 is economical enough to use on general utility services as well. Whether steam, water, air or chemicals and process gases, the Mark 2000 provides unparalleled flexibility for on/off service. Features • Actuator can be rotated 360° • Fast response • Maintenance-free actuator with long service life • Self-adjusting packing glands • Lower life-cycle costs • Compact design with high flow rates • Low air consumption due to small actuator volume • Water-hammer free design • Stainless Steel body trim for wide variety of media • Compact space saving actuator design • Position indicator (open/close) standard • Optional solenoid available Pneumatic Control Valves Mark 2000 Angle-Seat On/Off Control Valves Applications & Industries • Dyeing and washing machines • KEG washing and filling machines • Test benches, presses • Paint spray systems • Textile • Brewing • Automotive • Automotive/Chemical • Gas turbine test benches • Aerospace • "Clean in place" systems • Concrete and cement industry

Open the catalog to page 1

Mark 2000 Angle-Seat Valves Specifications -2- Description: In the "NCA" configuration, the medium enters the MK2000 under the seat such that the valve closes against the pressure of the flow. This 'closing against the flow' eliminates water hammer damage associated with liquid service (or condensate hammer in steam lines), but is also ideally suited for gas service as well. The "NCW" configuration 'closes with flow' and is primarily used on gas service. This option is used more frequently in larger valves as the pressure drop capability in the "NCA" configuration lowers. • The Mark 2000 is...

Open the catalog to page 2

Mark 2000 Angle-Seat Valves -3- Bill of Materials Part Number Description Part Number Description 1 Body 14 Packing Wiper 2 Bonnet 15 V-Ring Packing 3 Stem 16 Seat Retaining Bolt 4 Piston 17 Actuator Stem Seal 5 Valve Disc 18 Actuator Piston Seal 6 N/A 19 O-Ring 7 Seat 20 Clip Ring 8 Actuator Housing 21 Stem Nut 9 Flange 22 Body Bonnet Gasket 10 Disc 23 Spring 11 Bushing 24 Positive Indicator 12 Packing Spring 25 Indicator Cover 13 Packing Ring 8 20 10 12 22 14 3 5 7 16 1 15 2 13 9 19 17 11 18 4 21 23 24 25

Open the catalog to page 3All JORDAN VALVE catalogs and technical brochures

-

Jordan Valve Condensed Catalog

24 Pages

-

Mark 78 series

6 Pages

-

Mark ED, ET series

4 Pages

-

Mark DBAQ series

4 Pages

-

D, DA series

8 Pages

-

Mark V-100 Series

4 Pages

-

Mark 53/54 series

5 Pages

-

Mark 52 Series

4 Pages

-

Control Valves & Regulators

16 Pages

-

Mark 50 Series

16 Pages

-

Mark 63/64 series

6 Pages

-

Mark 58FT/58A

4 Pages

-

Mark 57

4 Pages

-

Mark 56

4 Pages

-

Mark 518 series

4 Pages

Archived catalogs

-

Condensed Catalog

24 Pages