Catalog excerpts

TYPE EZ-1® CARTRIDGE-MOUNTED METAL BELLOWS SEAL Technical Specification – Insert – Mating Ring – O-ring – Metal Bellows – Sleeve – O-ring – Centering Bushing H – Gland Packing I – Sleeve Collar J – Snap Ring A B C D E F G Welded Metal Bellows Product Description Performance Capabilities • Standard product for general-purpose applications. • Target markets are chemicals, pulp and paper, waste-water, food processing, and power generation. • Pressure: vacuum to 300 psig / 20 bar g • Speed: up to 25 m/s / 4500 fpm • Available with a hard-face combination for abrasive applications. • End play/axial float allowance 0.13 mm/0.005" F.I.M. max. • Alloy C-276 (UNS N10276) is an optional bellows metallurgy (upon special request). • Shaft runout: 0.001" per inch / 0.001 mm per mm of shaft diameter F.I.M. max. Design Features • Compact and easy to install • Only one moving part - the bellows • Eliminates O-ring “hang-up” problems • Self-cleaning bellows design

Open the catalog to page 1

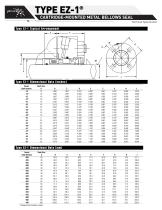

TYPE EZ-1® CARTRIDGE-MOUNTED METAL BELLOWS SEAL Technical Specification Type EZ-1 Typical Arrangement

Open the catalog to page 2

TYPE EZ-1® CARTRIDGE-MOUNTED METAL BELLOWS SEAL Technical Specification Pressure Ratings Pressure (bar g) Pressure (psig) To determine the maximum operating pressure for the size of the Type EZ-1 seal required, multiply the maximum pressure indicated on the graph above by the factors in the chart below. Consult John Crane for applications outside of these limits. Seal Size Multiplier Factors Selection Considerations Multiplier Factor Carbon vs. SiC SiC vs. SiC Example for Determining Dynamic Pressure Rating: Seal: 50mm/2" Type EZ-1 Between 400 and 3600 rpm Below 400 or above 3600 rpm...

Open the catalog to page 3

TYPE EZ-1® CARTRIDGE-MOUNTED METAL BELLOWS SEAL Technical Specification Materials of Construction SEAL COMPONENTS Sealide (Sintered Silicon Carbide) Mating Ring Sealide (Sintered Silicon Carbide) Sleeve Collar Centering Bushing Snap Ring 416 Stainless Steel (Hardened) Hardened Steel* Mating Ring O-ring PTFE-Encapsulated Fluorocarbon Sleeve O-ring Fluorocarbon (Installed) AFLAS®, EPR, PTFE-Encapsulated Fluorocarbon** Gland Gasket Glass-Filled PTFE Notes: * Hardened steel set screws provided with seal. 416 stainless steel screws are installed at the factory. ** These O-rings are provided with...

Open the catalog to page 4

TYPE EZ-1® CARTRIDGE-MOUNTED METAL BELLOWS SEAL Technical Specification Piping Plans The Type EZ-1 bellows cartridge seal provides a means of recirculating the product, flushing, or removing air from the seal chamber to extend seal life. The most popular piping plans are shown below for your reference. ANSI Plan 7311 (API Plan 11) This plan requires installation of a recirculation line from the pump case discharge through an orifice to the gland flush connection. The primary purpose of this plan is to dissipate heat generated at the seal faces and/or build seal chamber pressure. ANSI Plan...

Open the catalog to page 5

TYPE EZ-1® CARTRIDGE-MOUNTED METAL BELLOWS SEAL Technical Specification

Open the catalog to page 6

TYPE EZ-1® CARTRIDGE-MOUNTED METAL BELLOWS SEAL Technical Specification

Open the catalog to page 7

AFLAS is a registered trademark of Asahi Glass Co. LTD. North America Europe Latin America Middle East & Africa Asia Pacific United States of America United Kingdom Brazil United Arab Emirates Singapore If the products featured will be used in a potentially dangerous and/or hazardous process, your John Crane representative should be consulted prior to their selection and use. In the interest of continuous development, John Crane Companies reserve the right to alter designs and specifications without prior notice. It is dangerous to smoke while handling products made from PTFE. Old and new...

Open the catalog to page 8All John Crane catalogs and technical brochures

-

John Crane Couplings

4 Pages

-

L SERIES

8 Pages

-

Type 28VL

4 Pages

-

Type 93FR

4 Pages

-

TYPE 8648VRS

2 Pages

-

AURA™

2 Pages

-

SEAL FACE TECHNOLOGIES

2 Pages

-

H-RE

12 Pages

-

H-CE

12 Pages

-

CPKT

1 Pages

-

A series

8 Pages

-

TYPE 3604/3604HTC/3604HTCDP

8 Pages

-

TYPE 2800MB

8 Pages

-

TYPE 2715T

8 Pages

-

2609HTC/3609HTC

8 Pages

-

TYPE 1670

4 Pages

-

G58/G58I

2 Pages

-

CVU/CVH

2 Pages

-

CRANE-FOIL™

2 Pages

-

PACKING SOLUTIONS

2 Pages

-

CPR BUSHING

4 Pages

-

GR-2/2C

2 Pages

-

GR-1/1C

2 Pages

-

LIVE-LOAD

2 Pages

-

1345/1349

2 Pages

-

387I

2 Pages

-

Type 5611/5611Q

8 Pages

-

TYPE 502

6 Pages

-

TYPE 2106

4 Pages

-

AURA™ 180/220

4 Pages

-

TYPE 676

8 Pages

-

CLEARANCE SEALS

8 Pages

-

TYPE 2100

4 Pages

-

TYPE 21

6 Pages

-

TYPE 1/1B

6 Pages

-

Filter Elements

8 Pages

-

Combined Bearings

8 Pages

-

GR2/2C

2 Pages

-

GR1/1C

2 Pages

-

GP-S/GP-D

2 Pages

-

Cyclone Separators

4 Pages

-

Air-Cooled Heat Exchanger

2 Pages

-

682 Reservoir

2 Pages

-

Type 93FR

4 Pages

-

Type 83

4 Pages

-

Type 28XP

6 Pages

-

Type 28VL

4 Pages

-

Type 28ST

4 Pages

-

CK736/736D

4 Pages

-

SE2 ScrewPumps

4 Pages

-

SEW Ahlstar

4 Pages

-

Mechanical Packing

12 Pages

-

Tilting Pad Bearings

20 Pages

-

Engineered Coupling Solutions

12 Pages

-

Fuel Gas Filtration

8 Pages

Archived catalogs

-

Type 28AT_2015

8 Pages

-

Type 28AT_2012

6 Pages

-

Engineered Coupling Solutions

12 Pages

-

Water-Cooled Heat Exchanger

12 Pages

-

Type 2800 Control Panel

12 Pages

-

682 Reservoir

12 Pages