Catalog excerpts

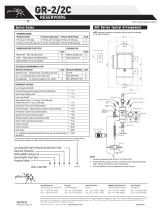

GR-2/2C A – Reservoir C B – Internal Cooling L Coil (GR-2C) K C – Level Switch D D – Weld Pad Level Gauge E – Pressure/ E Temperature Assembly F – Name Plate G – Hand Pump H – Safety Relief Valve I – Quick Connector J – Pressure Switch K – Orifice Union A L – Nitrogen Isolation Valve M – Drain Valve Non Stocked Options Fin Tube Air Cooler (not shown) Support Stand (not shown) B Circulation Pump (not shown) 3in1 Wireless Monitoring Device (not shown) Technical Specification NOTE: Hand pump and pressure switch are panel mounted. Panel is not shown. Instrument mounting varies depending on the option selected. D e s ig n Fe a tur e s/ Be nefi t s These general industry reservoirs provide buffer/barrier fluid to a dual seal arrangement. Key features: • 316/L stainless steel pressure reservoir without internal cooling coil (GR-2) or with internal cooling coil (GR-2C) • Design pressure: 30 bar g (435 psig), @100°C (212°F) • Minimum design temperature: -10ºC (14ºF) • Sight level gauge • 1/2" NPT reservoir terminations • Reservoir capacity: 7.7 litre (2 US gallons) • CE mark in accordance with Pressure Equipment Directive (PED) 97/23/CE provided to countries within the European Community • Welding in accordance with ASME VIII (welders qualified to ASME IX) • Many options available including: - Nitrogen isolation valve (for pressurized seals) - Orifice union (for unpressurized seals) O pti on Vari ants • Pressure gauge ranges • Compatibility with variable barrier/buffer fluid types • Electrical instruments suitable for: – Eexi circuits or Eexd (ATEX) – Explosion proof (UL/CSA) Materi al s of C onstructi on • Reservoir: 316/L stainless steel • Level gauge: weld pad, carbon steel cover, stainless steel wetted parts • Tube and fittings: 316/L stainless steel • Cooling coil: 316/L stainless steel (GR-2C only) A ppl icati ons • Automotive • Chemical processing •

Open the catalog to page 1

G R2 Series Typi cal A rrangem e n t PRESSURE RANGE Working Pressure Pressure Gauge Range Pressure Switch Range 0-6 bar g (0-100 psig) 0-10 bar g (0-150 psig) 0-6 bar g/0-100 psig 6-20 bar g (100-300 psig) max 0-25 bar g (0-360 psig) 6-20 bar g/100-300 psig BARRIER/BUFFER FLUID TYPE NOTE: Instrument mounting is indicative only and may vary depending on the options selected 1 Ø [6 5/8"] COOLING COIL Code Code M Without Cooling Coil N W With Cooling Coil C X Electrical Certification Code UL/CSA U ATEX WITH PED A ATEX WITHOUT PED S ELECTRICAL ENVIRONMENT TYPE Electrical Protection Explosion...

Open the catalog to page 2All John Crane catalogs and technical brochures

-

John Crane Couplings

4 Pages

-

L SERIES

8 Pages

-

Type 28VL

4 Pages

-

Type 93FR

4 Pages

-

TYPE 8648VRS

2 Pages

-

AURA™

2 Pages

-

SEAL FACE TECHNOLOGIES

2 Pages

-

H-RE

12 Pages

-

H-CE

12 Pages

-

CPKT

1 Pages

-

A series

8 Pages

-

TYPE 3604/3604HTC/3604HTCDP

8 Pages

-

TYPE 2800MB

8 Pages

-

TYPE 2715T

8 Pages

-

2609HTC/3609HTC

8 Pages

-

TYPE 1670

4 Pages

-

G58/G58I

2 Pages

-

CVU/CVH

2 Pages

-

CRANE-FOIL™

2 Pages

-

PACKING SOLUTIONS

2 Pages

-

CPR BUSHING

4 Pages

-

TYPE EZ-1®

8 Pages

-

GR-1/1C

2 Pages

-

LIVE-LOAD

2 Pages

-

1345/1349

2 Pages

-

387I

2 Pages

-

Type 5611/5611Q

8 Pages

-

TYPE 502

6 Pages

-

TYPE 2106

4 Pages

-

AURA™ 180/220

4 Pages

-

TYPE 676

8 Pages

-

CLEARANCE SEALS

8 Pages

-

TYPE 2100

4 Pages

-

TYPE 21

6 Pages

-

TYPE 1/1B

6 Pages

-

Filter Elements

8 Pages

-

Combined Bearings

8 Pages

-

GR2/2C

2 Pages

-

GR1/1C

2 Pages

-

GP-S/GP-D

2 Pages

-

Cyclone Separators

4 Pages

-

Air-Cooled Heat Exchanger

2 Pages

-

682 Reservoir

2 Pages

-

Type 93FR

4 Pages

-

Type 83

4 Pages

-

Type 28XP

6 Pages

-

Type 28VL

4 Pages

-

Type 28ST

4 Pages

-

CK736/736D

4 Pages

-

SE2 ScrewPumps

4 Pages

-

SEW Ahlstar

4 Pages

-

Mechanical Packing

12 Pages

-

Tilting Pad Bearings

20 Pages

-

Engineered Coupling Solutions

12 Pages

-

Fuel Gas Filtration

8 Pages

Archived catalogs

-

Type 28AT_2015

8 Pages

-

Type 28AT_2012

6 Pages

-

Engineered Coupling Solutions

12 Pages

-

Water-Cooled Heat Exchanger

12 Pages

-

Type 2800 Control Panel

12 Pages

-

682 Reservoir

12 Pages