Catalog excerpts

bodor loser Future is now T SERIES TUBE FIBER LASER CUTTING MACHINE Tube Laser Cutting Machine-T Series The equipment meets the parts processing requirements of most industries, working accuracy is stable. Selecting the optimal force and supporting structure, the overall mechanical property of equipment is perfect. Adopting cutting-edge optical concept to improve cutting performance. High speed cutting, auxiliary loading and unloading and efficient production reduce labor costs. At present, laser cutting machines have been widely used in electronics, electrical, mechanical hardware, new energy lithium, packaging, solar, LED, automotive and other industries. Product parameters Model Maximum machinable tube length Laser power X/Y-axis positioning accuracy X/Y-axis repositioning accuracy X axis maximum speed Y axis maximum speed Round tube Square tube Rectangular Tube Side Length Circumscribed circle diameter Wall thicknes of tubes (Diameter<cp50mm) Wall thicknes of tubes (Diameters* cp50mm) For more information, please go to the website : www.bodor.com

Open the catalog to page 1

The maximum cutting diameter is 30% longer than average products. The maximum bearing is 100% stronger. Suitable for a wide range of tubes.

Open the catalog to page 2

bodor loser Future is now Four-side Edge Searching, Higher Precision Brand new four-side edge searching Optimized method and algorithm Higher cutting precision and stability For more information, please go to the website : www.bodor.com

Open the catalog to page 3

bodor loser Future is now Self-centering Chuck Clamping jaws are driven by direct-current motor, whose electricity current is adjustable. Fast automatic centering and clamping is stable and suitable for a wide range of tubes. The clamping force is strong. Smaller chuck, lower rotating inertia, and stronger dynamic performance. Gearwheel transmission offers higher efficiency and longer service life. For more information, please go to the website : www.bodor.com

Open the catalog to page 4

Contour Recognition Stable and High Precision Use innovative photoelectric positioning replace the unstable capacitance positioning greatly improves recognition precision and stability Flash Recognition It takes only 0.8s to finish the recognition, and the processing can be started immediately Low Deviation for All Suitable Lengths The cutting spot deviation is within 0.15mm for tubes of all suitable lengths High Applicablity Automatic compensation for different tubes to achieve high-precision recognition for square tube, round tube, oval tube and waist tube. For more information, please go...

Open the catalog to page 5

Auto focus Applicable to multiple focal lengths, automatically adjusts focal position in cutting process by different sheet thickness. Free your hands Focal length is controlled by operating system, which effectively avoids errors or faults caused by manual operation. Simple and fast Applying Bodor lightning perforation technology reduce almost 90% work time. When technicist changes different metal sheet, Auto focus laser head can automatically read system storage parameters, which make the cutting process less gas, less electricity, lower cost, high efficiency. By setting perforation focal...

Open the catalog to page 6

bodor loser Future is now Bodor Thinker 3.0 Bodor Thinker 3.0 Q Smart control system supports NC code. No need for nesting software, direct support for cutting angle steel and channel steel. 2D and 3D display makes it intuitive and operable. Press one button to find the edges and align laser head. Process library makes it easy to operate. For more information, please go to the website : www.bodor.com

Open the catalog to page 7

bodor loser Future is now Tube Laser Cutting Machine-T Series Appearance design Aesthetics was introduced to industrial ID, perfect combination of technology and aesthetics. For more information, please go to the website : www.bodor.com

Open the catalog to page 8

bodor loser Future is now Loading: After the whole bundle pipes were put on the feeding device, these pipes can be intelligently divided, loaded and connected seamlessly with the pipe cutter to ensure that only one pipe is transported to the delivery arm at a time. Unloading: Finished material is automatically unloaded to the parts silo, double rollers auxiliary support long parts; materials can be automatic prepared during processing time, shorten the feeding time. Automatic unloading, parts and scraps are automatically separated, reducing sorting, saving labor, improving machine...

Open the catalog to page 9

I Material Laser power Thickness bodor loser Future is now Carbon steel Stainless steel Max cutting thickness (long-term using isn't recommended) Above data is only for reference For more information, please go to the website : www.bodor.com

Open the catalog to page 10

bodor laser Future is now

Open the catalog to page 11

Metal Samples For more information, please go to the website : www.bodor.com

Open the catalog to page 12

OFFICE For more information, please go to the website : www.bodor.com bodor loser

Open the catalog to page 13

WORKSHOP For more information, please go to the website : www.bodor.com

Open the catalog to page 14All Jinan Bodor CNC machine CO. catalogs and technical brochures

-

Laser Cutting Machine F

17 Pages

-

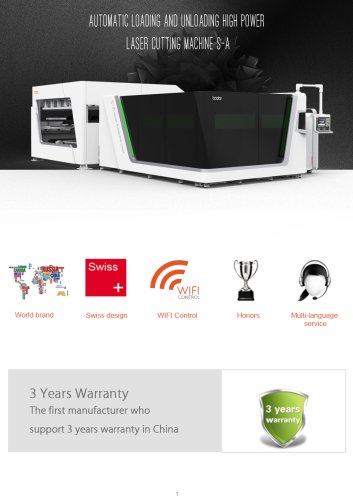

A-series

12 Pages

-

Tube Laser Cutting Machine T

8 Pages

-

Precise Laser Cutting Machine i3

10 Pages

-

Precise Laser Cutting Machine i5

10 Pages