Catalog excerpts

S SERIES HIGH-POWER FIBER LASER CUTTING MACHINE FOR METAL SHEET High Power Laser Cutting Machine - S Series Equipped with high/super power laser device, efficient thick plate cutting is no longer a dream, thin plate cutting is more speedy; BODOR database of cutting process will provide you with data support of performance and energy saving to save your cutting cost. Product parameters Model Working Area Laser Power X/Y-axis Positioning Accuracy X/Y-axis Repositioning Accuracy Max. linkage speed For more information, please go to the website: www.bodor.com

Open the catalog to page 1

bodor loser Future is now Flash Positioning It only takes 200ms to complete single image processing and 1 -3s to complete edge searching and positioning. 5 times faster than capacitance searching. Ultimate Precision Apply smart sensor system to achieve ±1.0mm comprehensive positioning precision and 0.1 mm max cutting precision, improving both material usage rate and product passing rate. Safety and Reliability Use digital processing to avoid the risk of probing collision of the following module, guaranteeing the safety. High Applicability Widen the application situations, suitable for not...

Open the catalog to page 2

Slag Treatment Process during Perforated Cutting of Thick Plates (Equipped with Beckhoff System) Smartly choose vortex process according to the material and its thickness, sparing the need for repeated adjustments and reducing operating difficulty. © Remove the slag produced during perforation to the greatest extent, improving the cutting effects and making sure that the cutting edges are smooth and material surface intact, (t) Greatly improve stability of cutting follower, and prolong service life of nozzle and ceramic ring. For more information, please go to the website : www.bodor.com

Open the catalog to page 3

bodor loser Future is now Unbounded Cutting Process for Cutting Leftover Material (Equipped with Beckhoff System) Automatic adjustment without programming, operating more easily. Cutting leftover materials, reduce waste, lower cost. 6 programs to realize arbitrary cutting of metal plate. For more information, please go to the website : www.bodor.com

Open the catalog to page 4

New generation of intelligent perforation technology ^ (Equipped with Beckhoff System) I f 1 I II ’ 7s #/ Piece Monitor Perforation Time Significantly reduce perforation time, average perforation time of medium & thick plate is reduced to 4s. Avoid blasting holes and avoid the failure of sheet overheating for prolonged perforation. The system automatically matches perforation parameters, which ensures the consistency of perforation parameters in continuous perforation process without repeatedly modification. For more information, please go to the website : www.bodor.com

Open the catalog to page 5

CAST IRON BEDA CAST IRON BED LAST FOREVER Material is more suitable Technique is more suitable Structure is more reasonable Clone production Pouring Mold, clone production; integrally formed, reject splicing Durable The usage of flake graphite with the lowest tensile strength of 200MPa gives the whole equipment strong shock absorption, wear resistance, high hardness, high carbon content, high compressive strength. Low notch sensitivity and thermal sensitivity of cast iron bed reduces the loss of equipment in using, keeps the precision of cutting unchanged permanently and no deformation in...

Open the catalog to page 6

Intelligent anti-collision 360°radar system can detect any obstacles in advance, and Z axis high-speed motion will be activated to immediately avoid obstacles, avoiding collisions. Higher Efficiency, Lower Cost This function Lowers the damage rate of laser head, and accordingly reduces maintenance cost, prolonging service life of the machine. Avoid production halt caused by collisions, ensuring continuous production. For more information, please go to the website : www.bodor.com

Open the catalog to page 7

Bodor Cutting 3.0 a 50“/» ;■ Carbon Steel Oxygen Fast Cutting (COF) Thick plate cutting realizes to doubles the speed while ensuring the cutting quality. 100% Low Nitrogen Pressure Fast Cutting (LNF) The nitrogen pressure reduces to 4Bar during cutting the 10mm stainless steel, its speed improves at least 10% than common cutting. Carbon Steel Economic Fast Cutting (CEF) At a specific power, cutting cost is only 10% of nitrogen cutting and creates more economic value for clients. For more information, please go to the website : www.bodor.com

Open the catalog to page 8

Automatic Nozzle Changer, Let Machine Know More About You Adopting abundant and accurate control system can realize automatic replacement of nozzles according to different materials and thicknesses, saving manual replacement time and improving processing efficiency, smart and convenient; Newest automatic calibration and cleaning functions can achieve fully automatic laser head calibration and nozzle cleaning, reducing the repetitive manual work; High-precision drive system provides a reliable replacement precision and stability to ensure that every replacement can be perfectly safe. Fully...

Open the catalog to page 9

High performance BECKHOFF Open Integrating Germany Beckhoff system Open Support customized development. Beckhoff can customize Bodor interface and Bodor specific features to support multi-touch screens and monitor device processing condition remotely. High performance EtherCat bus control provides quick signalling and high-accuracy of sync, especially for high-speed cutting. For more information, please go to the website : www.bodor.com

Open the catalog to page 10

The heavy bed makes theequipment more stable in working, the light crossbeam makes it work faster; perfect in--dtrstrtSTSesign is more in line with man-machine engineering; high quality electrical software control system gives equipment higher cutting precision. The machine owns more comfortable operation, more stable performance, more durable quality, higher cutting efficiency and wider application scope. " ' T t / /„ Intelligent travel protection Automatically monitor operation range of crossbeam and cutting parts, keeping operation within machining range. Double guarantees of fixed...

Open the catalog to page 11

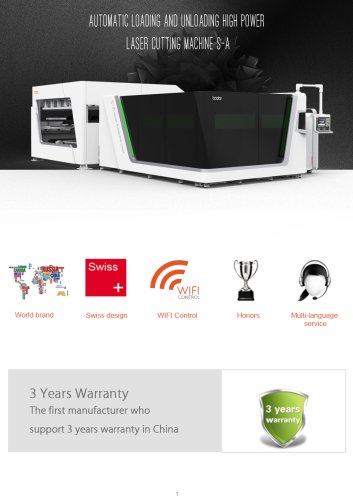

bodor loser Future is now High Power Laser Cutting Machine - S Series Appearance design Aesthetics was introduced to industrial ID, perfect combination of technology and aesthetics The Ul design lets display respond to processing table, making processing more intuitive. Meeting the certification standards of CE and FDA, fully enclosed design and strong exhaust system realize zero pollution to environment, laser protection glass realizes zero harm to human eyes. Built-in 1080P HD camera takes machining process in a glance. One button WiFi remote control, time-saving and high efficient....

Open the catalog to page 12All Jinan Bodor CNC machine CO. catalogs and technical brochures

-

Laser Cutting Machine F

17 Pages

-

A-series

12 Pages

-

Tube Laser Cutting Machine T

8 Pages

-

Precise Laser Cutting Machine i3

10 Pages

-

Precise Laser Cutting Machine i5

10 Pages