Catalog excerpts

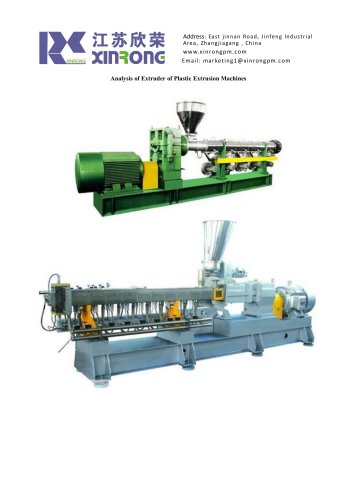

Te l : +8 6 15 1 62 3 55 1 16 Mail :t e rry@xi nron gpm .co m Aramid RTP Pipe Production Line For High Pressure Applications Reinforced thermalplastic pipe have been developed for high pressure pipeline, it is used in some applications to instead of the steel pipe because of its advantage of: Anti-corrosive Flexible High pressure up to 19 MPa Easy installation General Introduction High pressure fiberglass RTP pipe production line is xinrong’s another self-developed product after ten years’ of continuous research work and testing. This RTP pipe is reinforced by high strength fiberglass or aramid, customer could easily change for different number of fiberglass /aramid according to different pipe pressure rankings. It could be made up to 200bar (4 inches RTP pipe). This is an idea product for high pressure oil and gas application. xinrong’s High pressure fiberglass/aramid RTP pipe meet International standards like ISO Draft TS 18226: “Reinforced thermoplastic piping systems for gaseous fuels” and API RP 15S, 1st Edition API Recommended Practice “Qualification of Reinforced Plastic Line Pipe” etc. Structure of the pipe The feature of pipe’s structure is 6 aramid reinforced la

Open the catalog to page 1

Te l : +8 6 15 1 62 3 55 1 16 Mail :t e rry@xi nron gpm .co m Description Core Tube Extrusion Material: PVDF PVDF is used for liquid temperature no more than 150°C Reinforced layer winding Material: High strength aramid tape. The fiber is wrapped alternated clockwise and anti-clockwise as a fixed spiral angle of 55°44’, the customer can select different layers fiber for different pressure. Outer layer extrusion Material: PE Outside of pipe use PE. If need the scratch proof ability, could make a thin PP protection layer

Open the catalog to page 2

Address: East jinnan Road, Jinfeng Industrial Area, Zhangjiagang , China Tel: + 86 15162355116 Mail:terry@xinrongpm.com_ Pipe Specification Aramid RTP pipe specification

Open the catalog to page 3

Te l : +8 6 15 1 62 3 55 1 16 Mail :t e rry@xi nron gpm .co m RTP pipe jointing system Xinrong Company has developed crimp and expansion fittings which allows efficient joining directly to steel lines, standard flanged connections, or other RTP pipelines. The xinrong Company fitting is a metallic device that mechanically fastens to the pipe. The fitting can terminate the pipe with a standard ASME B16.5 lap-joint flange or a weld neck transition. The fitting consists of a mandrel which is inserted into the pipe, and a sleeve which is crimped around the pipe. The mandrel and sleeve are both...

Open the catalog to page 4

Te l : +8 6 15 1 62 3 55 1 16 Mail :t e rry@xi nron gpm .co m Hydraulic crimping fitting sleeve Finished pipe fitting Coupling fitting Prepare coupling fitting and pipes The other pipe inserted into fitting One pipe inserted into fitting Hydraulic crimping fitting sleeve for both sides Finished pipe coupling fitting Expansion steel pipe fitting

Open the catalog to page 5

Te l : +8 6 15 1 62 3 55 1 16 Mail :t e rry@xi nron gpm .co m How the fitting is made by expansion method Put steel fitting and taper rod on hydraulic device Put a steel sleeve outside of pipe and pull the taper Insert pipe Finished pipe fitting Cross section of the pipe fitting Bursting pressure test xinrong company have done countless tests for RTP pipe bursting pressure. Right now, it is easily to reach RTP bursting pressure at 400bar and above. It is no problem for even much higher pressure by simply increasing glass fiber numbers using xinrong’s new technology.

Open the catalog to page 6

Te l : +8 6 15 1 62 3 55 1 16 Mail :t e rry@xi nron gpm .co m RTP pipes used for bursting testing Long time pressure holding test Except short time bursting pressure, xinrong company have conducted its RTP pipe long time pressure holding test. We hold the pressure for 70 days at 200 bar, it proves there no any failure for both RTP pipes and fitting. Holding pressure device

Open the catalog to page 7

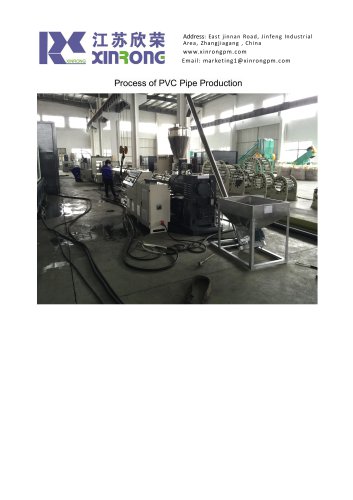

Te l : +8 6 15 1 62 3 55 1 16 Mail :t e rry@xi nron gpm .co m General Requirement 1. Applications: RTP pipe for onshore and offshore 2. Pipe diameter 2”,3” 4” 5” 6” 8’’RTP pipe 3. Working Pressure Reference to above table 4. Structure of the RTP pipe PERT/ARAMID TAPE/PVDF 5. Pipe Production Process The machine is in two steps process. First step is to produce the core tube for RTP pipe. And there is designed the co-extrusion in the core pipe, in case it needs to use the impermeable layer, then it can make the liner layer on the pipe.then move to the reinforced layer wrapping machine. 6...

Open the catalog to page 8

Address: East jinnan Road, Jinfeng Industrial Area, Zhangjiagang , China Tel: + 86 15162355116 Mail:terry@xinrongpm.com_ PVDF-A8inch ARAMID RTP Pipe Production Line 1. EQUIPMENT LIST PVDF RTP Pipe Extrusion:

Open the catalog to page 9All Jiangsu Xinrongplas Machinery Co. catalogs and technical brochures

-

Jiangsu Xinrongplas

1 Pages