Catalog excerpts

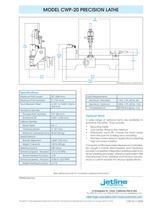

Product Information MODEL CWP-20 Precision Lathe One Model to handle a wide range of part sizes Precision Manufactured High Accuracy Rotation Wide Range of Accessories For all Arc Welding Processes Introduction The Jetline CWP-20 precision lathe is designed and built to provide superior accuracy and performance for even the most demanding GTAW (gas tungsten arc welding) or PAW (plasma arc welding) applications. The headstock, tailstock, frame, and carriage components are made of cast iron for stability and accuracy. The spindle has a 0.8” (20 mm) through-hole which can be used for gas purging or specialized tooling. The front of the spindle has a ange designed to accept the supplied three jaw chuck, four jaw chuck, and faceplate. Weight carrying capacity is 100 lbs (45 kg). The lathe accepts parts up to 20” (500 mm) in length with a maximum diameter of 5”(127 mm). Headstock spindle rotation has an accuracy of .001” (0.025 mm) TIR. Description Frame — The lathe’s cast iron frame has machined ways that mount the headstock and on which the tailstock and torch mounting carriage move. Headstock — The headstock spindle has a through-hole and rotates in the headstock housing on pre-loaded, tapered roller bearings. The bearings are designed to provide smooth, precise rotation and, because they are pre-loaded, also have the ability to carry the welding current. The headstock spindle is driven through a tensioned timing belt by a high-quality DC servo motor tted with a tach-generator. The supplied 9640 microprocessor control uses menu-driven software to permit the setting of rotational speed and the delays for the starting and stopping of travel. The control indicates speed before and during welding. — The tailstock slides on the precision ground ways on the frame of the lathe. A lever is provided to lock the tailstock when it is in its desired position. The tailstock uses a pneumatic spindle which extends to clamp the part into position when welding. Clamping pressure is adjustable; activation of the spindle movement is by a manual air valve. Tailstock The tailstock spindle has a Morse taper bore to accommodate a range of accessories. This can be used to hold an optional live center, faceplate, or custom designed tooling. — The torch mounting carriage slides on the machined ways of the frame. Positioning of the carriage along the length of the frame is through a manual wheel that engages a rack and pinon drive. Mounted on the top of the carriage is a micrometer adjustment slide used for manual fore/aft torch positioning. Torch Mounting The slide carries a vertical column that provides coarse vertical torch adjustment. A bracket mounted on the column carries a vee-style torch holder which is mounted on two precision slides for cross-seam and torch height adjustment. The bracket also includes manual tilt adjustment. 15 Goodyear St, Irvine, California 92618 U.S.A. • Tel: (949) 951-1515 • Fax: (949) 951-9237

Open the catalog to page 1

MODEL CWP-20 PRECISION LATHE Optional Items A wide range of optional items are available to enhance the lathe. They include: • Mounting Table • Live center, fitted to the tailstock • Pneumatic torch lift - moves the torch away from the part for loading and unloading • Precision motor drive for applications requiring high accuracy rotation Computer or Microprocessor Sequence Controllers, Arc Length Controls, Wire Feeders, and Oscillators provide completely integrated welding systems for all arc welding processes. Jetline is a specialist in the manufacture of arc welding controls and can pro-...

Open the catalog to page 2All Jet Line Engineering catalogs and technical brochures

-

MODEL 9700

2 Pages

-

Benchmaster

8 Pages

-

ALC- 701

4 Pages

-

Roll Planishers

4 Pages

-

Welding Chambers Brochure

4 Pages

-

Mechanized Oscillator

2 Pages

-

MODEL HWP-50E

2 Pages

-

COLD WIRE FEEDERS

4 Pages

-

cmc 100

1 Pages

-

MO-150-5A

2 Pages

-

Hand Crank Slides

1 Pages

-

shield all weld viewer

2 Pages

-

Seam Tracking Systems

4 Pages

-

Magnetic Arc Control Systems

4 Pages

-

9900 Controller

4 Pages

-

9600 control series

2 Pages

-

jetline capabilities

4 Pages

-

MODEL WHL Weld Head Locators

4 Pages

-

Circumferential Welders

6 Pages

-

ZB-300 Welding Positioner

2 Pages

-

Mechanical Weld Oscillator

2 Pages

-

Longitudinal Seamers

8 Pages

-

Hot Wire Tig Process

2 Pages

-

CWP Precision Welding Lathe

4 Pages

-

Automatic Seam Welders

2 Pages

-

ALC-401 Arc Voltage Control

4 Pages

Archived catalogs

-

Cold Wire Tig Feeder

4 Pages

-

ALC-101 Arc Length Control

2 Pages

-

9600 Microprocessor Control

2 Pages

-

9500 System Controller

4 Pages