Website:

JET EDGE

Website:

JET EDGE

Group: TC/American Monorail

Catalog excerpts

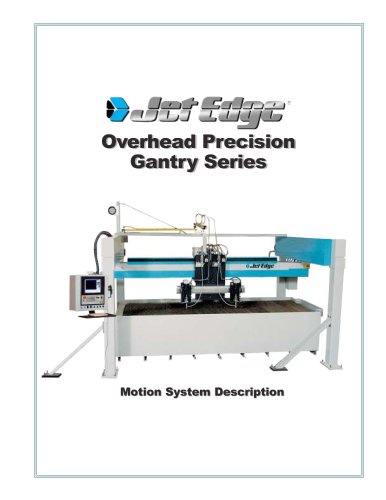

mid rail gantry A Cut Above the Competition • Industry Leading Precision and Accuracy! +/- 0.001" Linear positional accuracy (over 12") - per axis +/- 0.001" Repeatability (bi-directional) • Sturdy design ensures lasting precision. • Motion system separated from the catcher tank, eliminating vibration and ensuring maximum part quality. • Motion components are protected by metal covers with brush seals versus bellows that can puncture or tear. • 300 IPM contouring and 500 IPM rapid positioning (460V) • Easy to load with a forklift or crane. • Cuts virtually anything! • Optional mirroring - cuts part cycle time in half! Standard Features • Permalign EDGE Zero Taper/50° Bevel Cutting Head • Multiple Cutting Heads • Idler-type secondary Z carriage tied to primary Z carriage and manually adjusted; motorized or servo-driven 12” (304mm) height control (vertical travel). Follows primary Z; occupies 16” (406mm) of work envelope when parked. • Z axis AC brushless digital servo with absolute encoders • Secondary Z carriage: servo-motor driven, fully program mable with mirroring capabilities, motorized or servo-driven with 12" (304mm) height control (vertical travel); occupies 16" (406mm) of work envelope when parked. • Programmable contact height sensing on motorized Z • Water Raise/Lower for under-water cutting • Closed loop water system - eco-friendly • Abrasive removal system - reduces tank maintenance • CAD/CAM nesting software • Pneumatic drill • Stainless steel catcher tank and slat kits • Splash shields • Water level to follow Z axis travel (upward travel only) • Twin catcher tank bladders to decrease cycle time. • CE Mark Capable of cutting complex parts from virtually any material, this workhorse waterjet system is designed to provide years of dependable service in harsh industrial environments. Its sturdy design separates the motion system from the catcher tank, eliminating vibration and ensuring maximum part quality. The Mid Rail Gantry utilizes an industrial PC controller. It is ball-screw driven for optimal precision and features direct-couple AC brushless digital servo motors and single or double carriages. Critical bearing components are protected with heavy metal covers with brush seals and positive air pressure. Available in many sizes, from 5’x5’ (1500mm x 1500mm) to 24’x13’ (7300mm x 4000mm), the Mid Rail Gantry supports multiple cutting heads to maximize productivity. Optional mirroring capabilities make it possible to cut part cycle time in half. Optional Permalign EDGE technology eliminates taper and cuts bevels to 50°. Waterjet Pumps • Multiple models: 30-200hp (22-149kw), 60,000-90,000 psi (4100-6200 bar); intensifier and direct drive pumps available. The Aquavision Di Controller is the most advanced waterjet motion controller in the industry. Its customized Visual Basic front end guides the user through the process from job set-up to production. Single parts, mirroring, rotation, plate alignment and part arrays (optional) are right at your fingertips. It is fully networkable, allowing part programs to be generated offline and easily transferred to the system’s hard drive for production. • Table sizes: 5’x5’ to 24’x13’ (1500mm x 1500mm) to (7300mm x 4000mm) • 1 abrasivejet cutting head • Closed loop drive system on X & Y Axis • AC digital brushless servo motors, absolute encoders, SERCOS communication platform • Preloaded anti-backlash recirculating ball screws • Linear bearings with hardened precision ground ways • Split Y-axis drive system (dual motors) • Industrial PC controller • Variable feed-rate override for contouring and rapid motions • Individually controlled water and abrasive functions • Auto, MDI (manual data input) and manual operation • Full-featured hand-held pendant • High pressure whip delivery system with hand valve • Larger tables feature scissor arm high pressure plumbing to X-axis bridge; whip line high pressure plumbing to Z axis

Open the catalog to page 1All JET EDGE catalogs and technical brochures

-

ROBOTIC WATERJET SWIVEL

1 Pages

-

DENSE PHASE ABRASIVE HOPPER

1 Pages

-

FLUIDIZED ABRASIVE HOPPER

1 Pages

-

CONTACT HEIGHT SENSOR

1 Pages

-

IN-LINE WATER JET CHILLER

2 Pages

-

TACH-JET® Waterjet System

2 Pages

-

ip60-30 intensifier pump

1 Pages

-

FARM-JET® Waterjet System

2 Pages

-

xp90-50 intensifier pump

1 Pages

-

CUSTOM WATERJET SOLUTIONS

8 Pages

-

WATERJET PIPE CUTTER

1 Pages

-

ECO-JET PTO Pump

1 Pages

-

Water Jet Pipe Cutter

1 Pages

-

EDGE X-5 5-axis waterjet

1 Pages

-

BOSS-CUTTER Waterjet

1 Pages

-

eco-jet-direct

1 Pages

-

waterjet-slitter1

1 Pages

-

water-jet-pump-ip36-50

1 Pages

-

water-jet-pumps-iP55-200

1 Pages

-

P60-100-waterjet

1 Pages

-

water-jet-pumps-ip55-75

1 Pages

-

waterjet-pump-xp-90-501

1 Pages

-

water-jet-ultra-lite-lance

1 Pages

-

ersacutter-waterjet-cutter

3 Pages

-

deckblaster5

1 Pages

-

waterjet-blasting-gyra-jet

1 Pages

-

Rail-Gantry

1 Pages

-

garnet-delivery-systems

1 Pages

-

waterjet-pneumatic-drill

1 Pages

-

aquavision-di-high-rail1

1 Pages

-

waterjet-cutting-head

1 Pages

-

waterjet-cutting-head

1 Pages

-

waterjet-slitter

1 Pages

-

Mobile System Components

1 Pages