Catalog excerpts

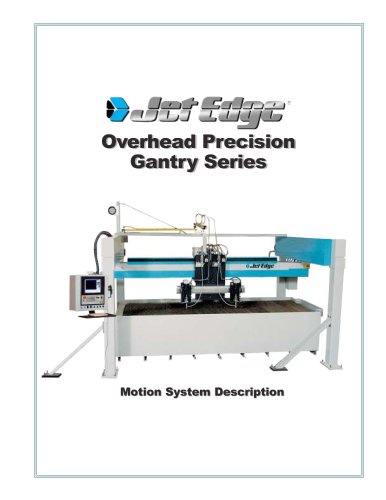

Motion System DescriptionMotion System Description >

Open the catalog to page 1

1.1 Bridge and Runway Construction The system legs are 7 x 7Ԕ x 3/8 steel tubesthat are secured to the foundation and provideleveling adjustment of the runway beams at thebottom of the legs. Runways are constructed of 8Ԕ x 12 x 3/8Ԕ wall rectangular steel tubes whichhave 1 1/4 x 2Ԕ steel ribs welded to the length ofthe runway. The 1 1/4 rib provides additional stiffness and is chalkfasted to provide a flatmounting surface. Chalkfast is a self-levelingcompound that levels within Ա.0002. This face inside the beam for additional rigidity with a1/2Ԕsteel plate welded on to cap the channel intoa...

Open the catalog to page 2

Preloaded Double-nut ballscrew Directly coupled servo on Runways Directly coupled servo on Bridge Two rails fastened on bottom with ballscrew One rail fastened on top >

Open the catalog to page 3

In order to eliminate any type of whippingaction of the ball screws, Jet Edge uses industry exclusive lead screw stabilizer blocks every 4 tosupport the ball screw. > Labyrinth lip seals and brush design Metal enclosures last the life of the machine.Abrasive material will wear through bellow enclosures which will cause contamination tocritcal areas. Wire supports are used under themetal enclosures to secure and protect all wiresthus eliminatingany electricalshortage concerns. > Industry exclusive lead screw stabilizer blocks Finally, Jet Edge finishes the system with arigid 1Ҕ 6061 T6...

Open the catalog to page 4

1.5 Multiple Cutting Heads and Spreader Bar Multiple cutting heads increase your productivity. Jet Edge has built a rigid system that can handlethis feature. With the overhead gantry waterjet system, the catcher tank is extended to accommodate the spreader bar thus increasing the work envelope.The total cutting area of the Model 610 is 6 by 10Ғ with one head as shown below. Model 610 10 foot cross axis The spreader bar is available in lengths of 36, 48Ԕ, 60, 72Ԕ, 90, and 96Ԕ. Spreader bars arelimited to four cutting heads, however, unique combinations will be reviewed by engineering....

Open the catalog to page 5All JET EDGE catalogs and technical brochures

-

ROBOTIC WATERJET SWIVEL

1 Pages

-

DENSE PHASE ABRASIVE HOPPER

1 Pages

-

FLUIDIZED ABRASIVE HOPPER

1 Pages

-

CONTACT HEIGHT SENSOR

1 Pages

-

IN-LINE WATER JET CHILLER

2 Pages

-

TACH-JET® Waterjet System

2 Pages

-

ip60-30 intensifier pump

1 Pages

-

FARM-JET® Waterjet System

2 Pages

-

xp90-50 intensifier pump

1 Pages

-

CUSTOM WATERJET SOLUTIONS

8 Pages

-

WATERJET PIPE CUTTER

1 Pages

-

ECO-JET PTO Pump

1 Pages

-

Water Jet Pipe Cutter

1 Pages

-

EDGE X-5 5-axis waterjet

1 Pages

-

BOSS-CUTTER Waterjet

1 Pages

-

eco-jet-direct

1 Pages

-

waterjet-slitter1

1 Pages

-

water-jet-pump-ip36-50

1 Pages

-

water-jet-pumps-iP55-200

1 Pages

-

P60-100-waterjet

1 Pages

-

water-jet-pumps-ip55-75

1 Pages

-

waterjet-pump-xp-90-501

1 Pages

-

water-jet-ultra-lite-lance

1 Pages

-

ersacutter-waterjet-cutter

3 Pages

-

deckblaster5

1 Pages

-

waterjet-blasting-gyra-jet

1 Pages

-

Rail-Gantry

1 Pages

-

garnet-delivery-systems

1 Pages

-

waterjet-pneumatic-drill

1 Pages

-

aquavision-di-high-rail1

1 Pages

-

waterjet-cutting-head

1 Pages

-

waterjet-cutting-head

1 Pages

-

waterjet-slitter

1 Pages

-

Mobile System Components

1 Pages