Website:

JET EDGE

Website:

JET EDGE

Group: TC/American Monorail

Catalog excerpts

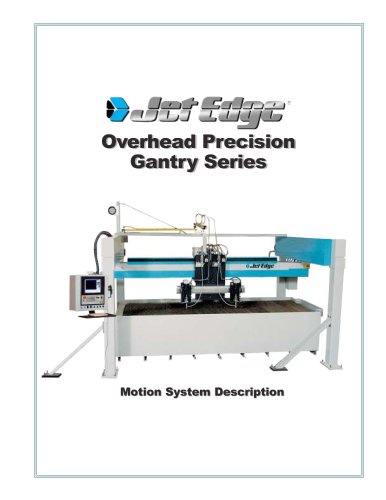

I he High Rail Gantry opens the work envelope for easier access and the overhead design raises critical components out of the processing environment. The isolated motion system and rigid steel beams makes this the most accurate waterjet cutter on the market. With 3-axis and 5-axis cutting options, multitable sizes and a Jet Edge UHP Pump, you’re prepared to cut some serious volume. HIGH RAIL GANTRY AT A GLANCE >- Easy access work envelope >- Motion components protected from harsh process environment >- Isolated motion system for accuracy >- Linear bearings, hardened precision ground ways >■ Direct-couple, AC brushless servo motors >- Preloaded anti-backlash recirculating ball screws >- Dual synchronized y-axis drive system >• Scissor arm and whip line high-pressure plumbing >- Technical service and free life-time factory training CONTROLS/ACCURACY > Aquavision DI fully networkable, industrial PC controller ) Digital readout for multi-head positioning > Full-featured hand-held pendant > Precision ball screws direcdy coupled to servomotors ) ±0.001" linear positional accuracy over 12" (304mm) per axis >• ±0.001" repeatability (bi-directional) >- ±0.003" renishaw ballbar tests of squareness and straightness over 24" (608mm) > ±0.0004" backlash - max. > 300-750 countouring and rapid positioning ) Motorized or servo-motor driven 12" (304mm) vertical travel height control ) Programmable secondary Z carriage, servo-motor driven 12" (304mm) height ) High pressure water and abrasive delivery monitors WARRANTY ) i-year or 2,000 hour warranty ) Extended warranties available ) Life-time product training CONFIGURATION OPTIONS ) 5-axis cutting head can cut bevels to 60° and eliminate tapers > Multiple 5-axis & 3-axis cutting heads can be mounted for mirroring capabilities ) Additional heads for slitting and secondary operations ) Laser surface mapping > CAD/CAM nesting software > Lights out cutting package >- Noise reduction and underwater cutting options ) Stainless steel catcher tank and slat kits ) Splash shields > Shuttle systems ENVIRONMENTAL WATER TREATMENT > Reverse osmosis for incoming water > Dual pressure water jet value ) Eco-friendly, closed loop filtration system ) Closed-loop chiller > In-line chiller > Abrasive removal system > Abrasive hoppers

Open the catalog to page 1All JET EDGE catalogs and technical brochures

-

ROBOTIC WATERJET SWIVEL

1 Pages

-

DENSE PHASE ABRASIVE HOPPER

1 Pages

-

FLUIDIZED ABRASIVE HOPPER

1 Pages

-

CONTACT HEIGHT SENSOR

1 Pages

-

IN-LINE WATER JET CHILLER

2 Pages

-

TACH-JET® Waterjet System

2 Pages

-

ip60-30 intensifier pump

1 Pages

-

FARM-JET® Waterjet System

2 Pages

-

xp90-50 intensifier pump

1 Pages

-

CUSTOM WATERJET SOLUTIONS

8 Pages

-

WATERJET PIPE CUTTER

1 Pages

-

ECO-JET PTO Pump

1 Pages

-

Water Jet Pipe Cutter

1 Pages

-

EDGE X-5 5-axis waterjet

1 Pages

-

BOSS-CUTTER Waterjet

1 Pages

-

eco-jet-direct

1 Pages

-

waterjet-slitter1

1 Pages

-

water-jet-pump-ip36-50

1 Pages

-

water-jet-pumps-iP55-200

1 Pages

-

P60-100-waterjet

1 Pages

-

water-jet-pumps-ip55-75

1 Pages

-

waterjet-pump-xp-90-501

1 Pages

-

water-jet-ultra-lite-lance

1 Pages

-

ersacutter-waterjet-cutter

3 Pages

-

deckblaster5

1 Pages

-

waterjet-blasting-gyra-jet

1 Pages

-

Rail-Gantry

1 Pages

-

garnet-delivery-systems

1 Pages

-

waterjet-pneumatic-drill

1 Pages

-

aquavision-di-high-rail1

1 Pages

-

waterjet-cutting-head

1 Pages

-

waterjet-cutting-head

1 Pages

-

waterjet-slitter

1 Pages

-

Mobile System Components

1 Pages