Catalog excerpts

Abrasive delivery systems Jet Edge offers two Abrasive Delivery Systems: the Solid Phase Abrasive Delivery System and the Fluidized Abrasive Delivery System. Using compressed air, each system creates an even distribution of abrasive flow that is essential to achieve reliable cutting results. The Solid Phase Abrasive Delivery System is used in most factory settings and employs a secondary metering system. Fluidized abrasive delivery is used when a secondary metering hopper is not practical, often in mobile cutting systems. Solid Phase Delivery For solid phase delivery, a pressurized hopper is used to force a solid stream of abrasive to a single cutting head or to multiple cutting heads. Each cutting head can be individually controlled to achieve its predetermined abrasive flow rate through the use of a secondary metering hopper. The secondary hopper has a pneumatically actuated slide gate that provides accurate metering and reliable on/off control of the abrasive. The metering system in the mini hopper consists of a dial wheel (four wheels available) with various holes that can easily be changed to achieve the desired flow rate of abrasive to the cutting head. Options Manual controls or advanced controls large capacity mini hopper Fluidized Abrasive Delivery Compressed air fluidizes and transports abrasive from a hopper to a single cutting head. Accurate metering and reliable on/off control of the abrasive is accomplished with a pneumatically actuated slide gate. An adjustment knob controls the slide gate opening for precise abrasive flow rates, and the indicating dial provides an accurate reference mark for the position of the slide gate. Available in manual control or remote control Abrasive delivery amplifier to extend abrasive feed tubing over 40 ft. Abrasive Delivery Hoppers Fluidized 400 3.5 43 in 36 in 25 in N/A 0.25-3 lbs/min Solid Phase 400 Solid Phase 800 Solid Phase 2500 Solid Phase 4200 3/5 6.5 20 35 42 in 48 in 60 in 85 in 24 in 34 in 46 in 46 in 24 in 30 in 36 in 38 in 235 340 785 1020 0/25-30+ lbs/min (supplies abrasive to up to 4 secondary hoppers Model/Capacity Lbs Capacity Cu/ft. Height Depth Width Weight Empty Lbs Delivery Rate Secondary Hopper 0.03 10 in 3.5 in 6 in 4.25 0.25-1.8 lbs/min

Open the catalog to page 1All JET EDGE catalogs and technical brochures

-

ROBOTIC WATERJET SWIVEL

1 Pages

-

FLUIDIZED ABRASIVE HOPPER

1 Pages

-

CONTACT HEIGHT SENSOR

1 Pages

-

IN-LINE WATER JET CHILLER

2 Pages

-

TACH-JET® Waterjet System

2 Pages

-

ip60-30 intensifier pump

1 Pages

-

FARM-JET® Waterjet System

2 Pages

-

xp90-50 intensifier pump

1 Pages

-

CUSTOM WATERJET SOLUTIONS

8 Pages

-

WATERJET PIPE CUTTER

1 Pages

-

ECO-JET PTO Pump

1 Pages

-

Water Jet Pipe Cutter

1 Pages

-

EDGE X-5 5-axis waterjet

1 Pages

-

BOSS-CUTTER Waterjet

1 Pages

-

eco-jet-direct

1 Pages

-

waterjet-slitter1

1 Pages

-

water-jet-pump-ip36-50

1 Pages

-

water-jet-pumps-iP55-200

1 Pages

-

P60-100-waterjet

1 Pages

-

water-jet-pumps-ip55-75

1 Pages

-

waterjet-pump-xp-90-501

1 Pages

-

water-jet-ultra-lite-lance

1 Pages

-

ersacutter-waterjet-cutter

3 Pages

-

deckblaster5

1 Pages

-

waterjet-blasting-gyra-jet

1 Pages

-

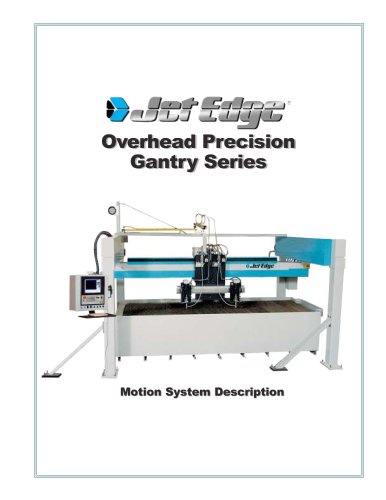

Rail-Gantry

1 Pages

-

garnet-delivery-systems

1 Pages

-

waterjet-pneumatic-drill

1 Pages

-

aquavision-di-high-rail1

1 Pages

-

waterjet-cutting-head

1 Pages

-

waterjet-cutting-head

1 Pages

-

waterjet-slitter

1 Pages

-

Mobile System Components

1 Pages