Website:

JET EDGE

Website:

JET EDGE

Group: TC/American Monorail

Catalog excerpts

spyder abrasivejet circle & radius cutting system A Cut Above Suitable for any environment: • Cuts virtually any material without heat or flames • Pneumatic reversible drive motor • Non-ferrous motion components Easy Set Up: • Self-aligning • Lighweight suction cup mount Available in two sizes: • 1”-6.5” insider diameter/16“-48” outside diameter • 3“-12.5” inside diameter/27.5“-56” outside diameter Movement Speed: Varies due to several ranges of gear reducers Optional Linear and Pipe Cutting Tracks: • 3, 5 and 10 linear-foot tracks • Low profile, rigid and vacuum tracks available • Pipe track: 6–60 inches (152–1524 mm) Master Control Station • Three-position directional valve for pneumatic drive unit • Dual air regulators for directional speed control • Control abrasive flow from console • One palm button shuts o UHP water and abrasives Vacuum Generator • Steel construction • Pneumatic control vacuum • Locking quick disconnects • Lightweight compact design Designed for use in remote and potentially hazardous environments, Jet Edge’s Spyder Head Manipulator Abrasivejet Radius and Circle Cutting System • Drive unit adapts for use with track or pipe cutting bands • Pneumatic reversible drive motor with interchangeable gear drive can be set up on the side of tanks, small • Precise speed control for accurate cutting feed rates vessels and large diameter piping. It is held • Center line mounting of abrasive cutting head in place by vacuum cups and features a • Adjustable angle for beveling cuts self-aligning centering pin for fast and Permalign® II Abrasive Head reliable setup. Motion components are Length 10.94 in (27.8 cm) Weight 4 lbs ( 1.8 kg) made from non-ferrous materials, and Operating air pressure (min) 60 psi (4 bar) cutting head manipulators are powered by Water pressure (max) 60,000 psi (4100 bar) pneumatic motors, making the Spyder Orifice range .005 - .021 in (.127 - .53 mm) Nozzle range .020 - .065 ID (.508 - 1.65 mm) suitable for use in all environments. Max flow rate 2.1 gpm (7.95 lpm) High Flow Abrasive Head (for cutting thicker material or multiple layers) Length 7.55 in (19.1 cm) Weight 4.00 lbs ( 1.8 kg) Operating air pressure (min) 60 psi (4 bar) Water pressure (max) 45,000 psi (3100 bar) Orifice range .020 - .036 in (.51 - .91 mm) Nozzle range .095 - .125 ID (2.41 - 3.18 mm) Max flow rate 5.1 gpm (19.04 lpm) A master control panel allows operators to control the cutting head manipulators, direction, speed of travel, abrasive delivery and vacuum components from one location. powered by jet edge! The Riding Deckblaster is powered by a Jet Edge waterjet intensifier pump. Abrasive Delivery System • Lightweight durable high-impact poly design • Two-wheel pneumatic tires with rigged frame • Air-regulated metering valve • Delivery rate: up to 3 lb (1.36 kg)/minute Model iP55-280DS Specifications subject to change.

Open the catalog to page 1All JET EDGE catalogs and technical brochures

-

ROBOTIC WATERJET SWIVEL

1 Pages

-

DENSE PHASE ABRASIVE HOPPER

1 Pages

-

FLUIDIZED ABRASIVE HOPPER

1 Pages

-

CONTACT HEIGHT SENSOR

1 Pages

-

IN-LINE WATER JET CHILLER

2 Pages

-

TACH-JET® Waterjet System

2 Pages

-

ip60-30 intensifier pump

1 Pages

-

FARM-JET® Waterjet System

2 Pages

-

xp90-50 intensifier pump

1 Pages

-

CUSTOM WATERJET SOLUTIONS

8 Pages

-

WATERJET PIPE CUTTER

1 Pages

-

ECO-JET PTO Pump

1 Pages

-

Water Jet Pipe Cutter

1 Pages

-

EDGE X-5 5-axis waterjet

1 Pages

-

BOSS-CUTTER Waterjet

1 Pages

-

eco-jet-direct

1 Pages

-

waterjet-slitter1

1 Pages

-

water-jet-pump-ip36-50

1 Pages

-

water-jet-pumps-iP55-200

1 Pages

-

P60-100-waterjet

1 Pages

-

water-jet-pumps-ip55-75

1 Pages

-

waterjet-pump-xp-90-501

1 Pages

-

water-jet-ultra-lite-lance

1 Pages

-

ersacutter-waterjet-cutter

3 Pages

-

deckblaster5

1 Pages

-

waterjet-blasting-gyra-jet

1 Pages

-

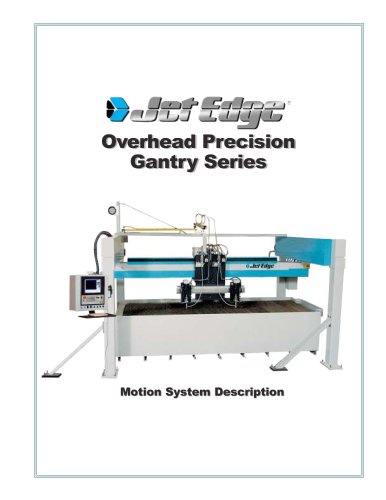

Rail-Gantry

1 Pages

-

garnet-delivery-systems

1 Pages

-

waterjet-pneumatic-drill

1 Pages

-

aquavision-di-high-rail1

1 Pages

-

waterjet-cutting-head

1 Pages

-

waterjet-cutting-head

1 Pages

-

waterjet-slitter

1 Pages

-

Mobile System Components

1 Pages