Website:

JEAN BREL

Website:

JEAN BREL

Catalog excerpts

Normfinish Blast cabinet DI Injector Blasting BLAST CABINETS – BLAST ROOMS – ACCESSORIES - ABRASIVES

Open the catalog to page 1

IN-HOUSE PRODUCTION Normfinish blast cabinets are developed and manufactured by Leering Hengelo for many decades. Normfinish blast cabinets are intended for frequent blasters with high demands on the blasting results, clear view, user convenience, safety and the environment. All components are assembled, according to ISO-certification, to create a compact turn-key unit. More information:

Open the catalog to page 2

Blast cabinet DI INJECTOR BLASTING Easy to replace splash glass Normfinish blast cabinets guarantee the following: • Efficient powerful blasting Door safety switches • lasting process free of interruption B • ontinuous clear view due to optimal C circulation of air • abinet without foundations, C compact construction • fficient cleaning of abrasives E by cyclone Pressure gauge for displaying system pressure

Open the catalog to page 3

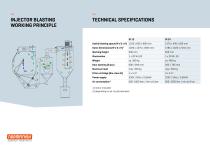

INJECTOR BLASTING WORKING PRINCIPLE TECHNICAL SPECIFICATIONS Useful blasting space (W x D x H) 1105 x 800 x 800 mm Working Height Maximum load Filter cartridge (Bia-class M) Power supply 1) motor included 2) depending on air nozzle diameter

Open the catalog to page 4

ADDITIONAL OPTIONS FOR DI MODELS • tationary rotary table S • omplete rail system, including C mobile rotary table • ixed blast gun holder (adjustable) F • yclone with removable lid and C Linatex protective lining • hroughput tunnel, various T models available • rotective lining front, backside and doors P • ptions such as roller conveyors O on request Rotary basket with blast gun holder Complete rail system, including mobile rotary table (DP) Throughput tunnel HEPA filter

Open the catalog to page 5

The automation of production processes continues and equipment is becoming increasingly productspecific. As a result, traditional equipment is often no longer up to the task. Leering Hengelo has its own engineering department, which is why our company can respond to the many questions raised in this area. In addition to producing new machinery and equipment, Leering Hengelo also places great importance on professional aftercare and service. With this in mind, we have our own service department with skilled technicians. They are not only experts when it comes to our own equipment, but also...

Open the catalog to page 6All JEAN BREL catalogs and technical brochures

-

Normfinish Mistral-series

6 Pages

-

CJC Cleaning Tables

8 Pages

-

VIBREURS CIRCULAIRES

11 Pages

-

Durashot HC

1 Pages

-

POWERTRACK

4 Pages

-

Duragrit HC

1 Pages