Website:

JEAN BREL

Website:

JEAN BREL

Catalog excerpts

Normfinish Automated customised blast installations BLASTING – CLEANING – TOOLS AND MACHINES

Open the catalog to page 1

IN-HOUSE ENGINEERING AND PRODUCTION The automation of production processes continues and equipment is becoming increasingly productspecific. As a result, traditional equipment is often no longer up to the task. Normfinish automated blast installations are developed and produced by Leering Hengelo. Our own engineering department can respond to the many questions raised in this area. We are able to translate customerand product-specific requirements into customised equipment perfectly suited to your application(s), ISO 9001:2015 certified. Whether you need paint removal, roughening for a...

Open the catalog to page 2

SATELLITE BLAST INSTALLATIONS BATCH Suitable to totally blast complex parts (rotate the products and oscillate the nozzles). The products do not come into contact with each other; therefore, nothing will be damaged. Indexing the blasted product beyond the installation and then replaced by a non-blasted product. Meanwhile, the next product is blasted. Loading/unloading can perfectly be done with the help of a robot. Satellite Blast Installations

Open the catalog to page 3

TRANSIT BLAST INSTALLATIONS INDEX Suitable for the blasting of products that are supplied individually. After importing the products, the doors close. The products are completely blasted by an oscillating movement of the nozzles (back and forth) and a horizontally shifting motion of the products. Blasting can take place above, underneath or on both sides. It is suitable to align with other product machines. CONTINUOUS Especially suitable for a continuous process. Transit Blast Installations

Open the catalog to page 4

TURNTABLE BLAST INSTALLATIONS Suitable for blasting larger, usually round-shaped products. Products are placed on a turntable and are blasted by the rotation of the table in combination with the oscillating nozzle movement. The turntable can be placed permanently in the cabinet. Or brought outside the cabinet with a transport system, so that loading using a crane/forklift is possible. Turntable Blast Installations

Open the catalog to page 5

DRUM BLAST INSTALLATIONS BATCH Particularly suitable for the automatic and complete blasting of small parts. Used often to finish 3D printed products. When blasting Aluminium, Titanium, PA or PP parts, an explosive-secured execution thereof is required. This may, for example, consist of a rotary lock valve, rupture disk, Ex motor and fan, non-return valve and/or flow control. Drum Blast Installations

Open the catalog to page 6

INTERNAL BLAST INSTALLATIONS Suitable for efficient cleaning of the inside of hollow products, such as gas bottles, fire extinguishers, tanks, etc. After installation, the product is rotated and the nozzle makes up-and-down movements. Internal Blast Installations More info:

Open the catalog to page 7

SHOT PEEN BLAST INSTALLATIONS The blasting medium is sieved and it is optional possible to control the roundness. The dosage of the blasting medium can optionally be controlled. This can be carried out in all the above-mentioned blast cabinets.

Open the catalog to page 8

DIFFERENT MODELS Referred to customised type of blast installations can be delivered in different models. Below are a couple of examples. Different Models 1 recharge blasting medium for a constant business mix > blast result 2 several formulas to programme via HMI/PLC, pressure setting and control via HMIdrukinstelling en controle via HMI HEPA filter, dust detection etc. Sieve unit

Open the catalog to page 9

SERVICE & MAINTENANCE Taking in production the blast installation includes training with respect to its use and maintenance. An extensive manual is of course supplied. You can always reach us via the number below if you have any questions. We have our own service personnel with experts and (certified) technicians. Visiting address Barnsteenstraat 1 7554 TC Hengelo (OV) The Netherlands

Open the catalog to page 10All JEAN BREL catalogs and technical brochures

-

Normfinish Mistral-series

6 Pages

-

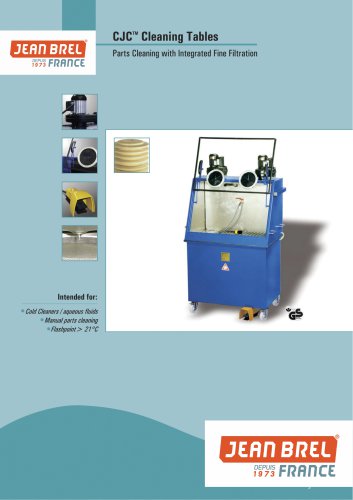

CJC Cleaning Tables

8 Pages

-

VIBREURS CIRCULAIRES

11 Pages

-

Durashot HC

1 Pages

-

POWERTRACK

4 Pages

-

Duragrit HC

1 Pages

-

Normfinish Blast cabinet DI

6 Pages