Catalog excerpts

Continuous Hydrostatic Sterilizer

Open the catalog to page 1

JBT Hydromatic : Adding Value to Your Products ® Tailor made shelf-life solutions. The reputation of your brand is only as good as the quality of your products. Producing the best possible quality is one thing; making sure your production is at the highest level of efficiency and at an ever lower cost is quite another. To effectively address new consumer needs, packaging trends and opportunities in the market, you need a processing system which can be adjusted or extended and, at the same time, offers you a very strong economic proposition: you need the JBT Hydromatic. Each JBT Hydromatic...

Open the catalog to page 3

JBT Hydromatic : Cost-Effective and Flexible ® The JBT Hydromatic is the solution for the sterilization of both medium and large production volumes. Production cost of products manufactured in large quantities require the highest level of efficiency and the lowest cost. This requires adapting to a variety of recipes and processes, in different packages and relatively small production batches. To stay flexible enough to accommodate a variety of packaging types and sizes, your system must have the capability for efficient changeover. The market requires the JBT Hydromatic.

Open the catalog to page 4

Lowest cost per unit The JBT Hydromatic is an advanced continuous sterilizing system which in many cases has proven to provide the lowest cost per container. This is the result of the JBT Hydromatic's incredibly efficient and fully automatic operation, energy-efficient design, long service life and low maintenance costs. Energy and water savings Inherent in the JBT Hydromatic’s unique design is a very high level of water recycling and heat regeneration, resulting in extremely low energy and water usage. The JBT Hydromatic reduces the processing cost of your product while helping you achieve...

Open the catalog to page 5

Configurations JBT Hydromatic sterilizers are designed and built to your requirements. Increasing product and packaging diversification has sparked the development of many new Hydromatic configurations with or without overpressure as well as other special features. Based on a detailed analysis of your current and future needs, each JBT Hydromatic is configured from well-proven components, linked together to form a tailor-made solution. This ensures you will receive the best possible return on your investment! Different product/packaging concepts High or low capacity? Flexible or...

Open the catalog to page 6

Meet the family To provide maximum efficiency, reliability and the best possible technology for your specific requirements, the JBT Hydromatic family consists of different concepts. Each concept has specific characteristics but shares ‘family values’ such as great flexibility, high reliability, and very low level of energy consumption and operating cost. Side loader The product carrier consists of two tubes (or channels) fitted to the main conveyor chain. Product containers are loaded into and unloaded from the tubes at the side of the carriers. The carriers are closed during the entire...

Open the catalog to page 7

Anything Goes A JBT Hydromatic Continuous Sterilizer is used to process any product in a wide variety of packaging. Applications include ready meals, vegetables, meat, fish, pet food, soup, low-acid drinks, dairy products, soy drinks, etc. Baby food Baby food is usually packed in small decorated cans or glass jars with PT-closure requiring an overpressure process. This is achieved with a twin hydrostatic tower system configuration. A specially designed soft-touch system handles the jars with extreme care at speeds of up to 1200 jars per minute. Vegetables and meal components You will find...

Open the catalog to page 8

Pet food Hydromatics are used by leading manufacturers in the pet food industry all over the world. The JBT Hydromatic system in many cases has proven to provide the most economical solution for the range of cans (from the smallest one-portion cat food can to the largest dog food cans). The system design accommodates the typical requirements of the industry, such as high-line speed and round-the-clock operation. A special version of the JBT Hydromatic is available for lightweight aluminum tubs (trays), using a special handling system and hanging carriers, which allows the tubs to always be...

Open the catalog to page 9

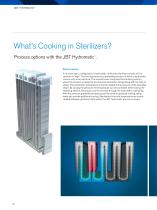

What’s Cooking in Sterilizers? Process options with the JBT Hydromatic . ® Basic process In its most basic configuration, a hydrostatic continuous sterilizer consists of four sections or “legs”. The first leg serves as a preheating section, in which a hydrostatic column acts as an inlet lock. The second tower comprises the sterilizing section, where the product is heated to the requisite sterilization temperature with the help of steam. The sterilization temperature is directly related to the pressure of the saturated steam. By varying the pressure, the temperature can be controlled. After...

Open the catalog to page 10

Overpressure sterilization Much of the new generation of packages are more “sensitive” to process conditions than traditional packages. This is mainly due to the construction of the materials (plastic, very thin metal and sensitive closures). The common process requirement for packages like trays, tubs, glass jars, plastic pots and plastic bottles is the need for an overpressure process. This means that additional pressure is required during the process. For overpressure sterilization, the JBT Hydromatic applies either a mixture of steam and compressed air (effectively homogenized by a...

Open the catalog to page 11

Production Made Easy Advanced control system Variety change system Each JBT Hydromatic sterilizer features an advanced automatic control and management system which is FDA compliant for the US market. The Variety Change System includes a recipe memory in which the various process parameters and alarm limits for the relevant processes are stored. The information provided by the control system keeps the operator fully informed and important data is recorded for future reference. Product monitoring system The Product Monitoring and Registration System (PMR system) monitors the product in the...

Open the catalog to page 12All JBT Corporation catalogs and technical brochures

-

Water filtration

4 Pages

-

Avure HPP AV-X

4 Pages

-

Avure HPP AV-10

4 Pages

-

Avure HPP AV-S

4 Pages

-

Case Packing Machine

2 Pages

-

Wet Pet Food Tecnology

6 Pages

-

Static Retort

8 Pages

-

Energy Recovery System

2 Pages

-

Rotary Pressure Sterilizer

12 Pages

-

Tuna Cooker

4 Pages

-

Tuna Filler 3266

4 Pages

-

Vibrating System

13 Pages

-

Air Cleaner

4 Pages

-

Transportation Equipment

6 Pages

-

Wahers

6 Pages

-

SuperStatic Retort

4 Pages

-

FVPGrow

4 Pages

-

Chopper/Blender SE

4 Pages

-

JBT PLF Virtus

4 Pages

-

SuperCRss™

4 Pages

-

Brush-Bed-System-A19018-EN

2 Pages

-

Citrus-Extractor-423

4 Pages

-

AsepTec® Linear Filler

4 Pages

-

Bulk Aseptic Fillers

8 Pages

-

PF 200 Pulper Finisher

4 Pages

-

Citrus Finisher Applications

2 Pages

-

Model FTE Juice Extractor

4 Pages

-

T.A.S.T.E. Evaporator

8 Pages

-

READYGo™ CHOPPER / BLENDER

4 Pages

-

Corn Cutter Model SC-120

2 Pages

-

Hot Break System

2 Pages

-

Cold Break System

2 Pages

-

Produce Plus Juicer

4 Pages

-

READYGo™ JUICE FAMILY

8 Pages

-

NGS Series Beltroll Sizer

4 Pages

-

Apple Processing Lines

8 Pages

-

Magnetic Onion Peeler

6 Pages

-

Flotation Wash Line

6 Pages

-

DCC Belt Steamer

8 Pages

-

G-3 Labeling System

2 Pages

-

FLEX-ID System

2 Pages

-

Quick Change Brush Mount

2 Pages

-

Single Pass Dryer

2 Pages

-

SaniClean® Belt Conveyor

2 Pages

-

Freshgard® Chemtrol

2 Pages

-

Brush Bed System

2 Pages

-

Bin Scrubber System T-Series

2 Pages

-

Bin Scrubber System S-Series

2 Pages

-

Rotary weight Filler

4 Pages

-

X59-Can-Closer

4 Pages

-

SeamTec

2 Pages

-

Tuna

2 Pages

-

Unifiller

8 Pages

-

XL-series Piston Filler

2 Pages

-

Rotary level filler

4 Pages

-

Rotary Granular Filler

4 Pages

-

Pet Food Processing

8 Pages

-

Flash-Cooler

4 Pages

-

Heat Exchangers

4 Pages

-

SteriCompact

2 Pages

-

UHT Processing Lines

8 Pages

-

Sterideal Ohmic

4 Pages

-

MEDALLION

4 Pages

-

Aseptic_Filler

8 Pages

-

FranRica

2 Pages

-

BottleTec

2 Pages

-

AsepFlex_Linear_Pouch_Filler

4 Pages

-

Pulper-Finisher

4 Pages

-

GTRe

2 Pages

-

GT1-Lid Machine

2 Pages

-

AP60

2 Pages

-

GT5eX-Twin

2 Pages

-

GT4e

2 Pages

-

GTeX-Twin

2 Pages

-

GT2e

2 Pages

-

GT1e

2 Pages

-

GT0e

2 Pages

-

GT2sX-Twin

2 Pages

-

GT2s

2 Pages

-

GT1s

2 Pages

-

GT0s

2 Pages

-

TASTE Evaporator

8 Pages

-

Hybrid Evaporator

4 Pages

-

READYGo CHOPPER BLENDER

4 Pages

-

Chopper/Blender

4 Pages

-

Pumpideal

4 Pages

-

Rubber Cord Scrubber

2 Pages

-

READYGo EXTRACTION

4 Pages

-

Tomato Peel Pinch Bed

2 Pages

-

Tomato Peeling System

8 Pages

-

Hot Break

2 Pages

-

Cold Break

2 Pages

-

Roller Spreader

2 Pages

-

READYGo JUICE SJE

4 Pages

-

READYGo JUICE DJE

4 Pages

-

READYGo d-LIMONENE

4 Pages

-

Brush Washer

2 Pages

-

Beltroll Sizer

4 Pages

-

Apple Deaerating System

2 Pages

-

Apple Preparation System-C8A

4 Pages

-

Freshline centrifuge

4 Pages

-

Super Batch Centrifuge

4 Pages

-

Swirl bath washer

6 Pages

-

Weighing conveyor

2 Pages

-

Multifunctional washer

4 Pages

-

Knocker conveyor

4 Pages

-

Horizontal centrifuge

4 Pages

-

DCC Screw steamer

4 Pages

-

Belt Steaming System

8 Pages

-

Crate Washer

4 Pages

-

Bin Tipper

4 Pages

-

Air Dryer

4 Pages

-

Belt Cooler

2 Pages

-

AV Sealer

2 Pages

-

Juice Extractor

4 Pages