Website:

Jäger Umwelt-Technik GmbH & Co. KG

Website:

Jäger Umwelt-Technik GmbH & Co. KG

Catalog excerpts

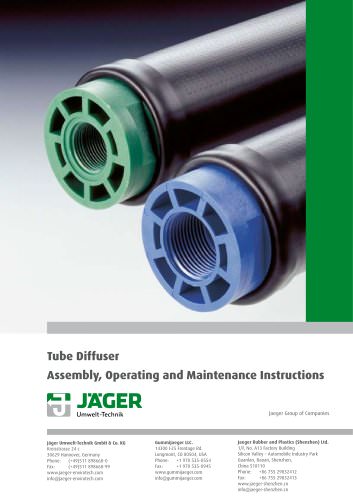

Tube Diffuser Assembly, Operating and Maintenance Instructions Jaeger Group of Companies Jäger Umwelt-Technik GmbH & Co. KG Kreisstrasse 24 c 30629 Hannover, Germany Phone: (+49)511 898668-0 Fax: (+49)511 898668-99 www.jaeger-envirotech.com info@jaeger-envirotech.com GummiJaeger LLC. 14300 I-25 Frontage Rd. Longmont, CO 80504, USA Phone: +1 970 535-0554 Fax: +1 970 535-0945 www.gummijaeger.com info@gummijaeger.com Jaeger Rubber and Plastics (Shenzhen) Ltd. 1/F, No. A13 Factory Building Silicon Valley – Automobile Industry Park Guanlan, Baoan, Shenzhen, China 518110 Phone: +86 755 29832412 Fax: +86 755 29832413 www.jaeger-shenzhen.cn info@jaeger-shenzhen.cn

Open the catalog to page 1

6.3 INSTALLATION (type 63/0 only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 8.2 REPLACING TUBE DIFFUSER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Open the catalog to page 2

1. Aeration Systems This manual describes in detail the installation and operating of tube diffuser JetFlex TD 63/0 with perforation lenghts of 500, 750 and 1000 mm, respectively. 2. General Jäger Umwelt-Technik GmbH & Co. KG (JUT) supplies diffuser for diffused air aeration in residential and industrial waste water treatment plants. The diffusers deliver fine bubble aeration suitable for the efficient treatment of wastewater treatment plants using the activated sludge process. Specially formulated EPDM compounds with high and durable elasticity allow a long-term intermittent operation...

Open the catalog to page 3

Prior to assembly of the aeration system remove all debris (stones, metal scrap, wooden pieces etc.) from the aeration tank. Stainless steel square tubes (80 x 80 mm or 100 x 100 mm) are recommended as laterals for JetFlex TD 63/0 diffusers with SS-connectors. Standard round lateral tubing require the use of a special clamp. See TD 65/2 data sheet. All laterals must be levelled within ± 6.35 mm (± 1/4”) for proper function of diffusers. Air outlet holes in lateral for each diffuser must be predrilled and adjusted in accordance to the individual data sheets. Hole diameter ± 0.1 mm,...

Open the catalog to page 4

7 Operating Instructions 7.1 Start-Up Instructions Prior to start-up clean the aeration tank from debris like stones, wooden pieces, metal parts etc. Keep the time between assembly and filling of the basin as short as possible. Ohterwise take the following steps: • • • • • • • Do not perform any work near the diffuser or above the aeration tank, which may damage diffusers; e.g. painting, welding, concrete sealing etc. Safeguard diffusers from falling parts. Fill tank with clean water approximately 20 cm above diffusers. Start blowers for 5 - 10 minutes and check for obvious leaks. Have...

Open the catalog to page 5

Specifications 7.3 Trouble Shooting JetFlex Diffusers need very little maintenance even for long-term operation due to their high-performance materials. JUT recommends regular inspection intervals every 12 to 18 months in order to monitor fouling processes. Check pressure loss permanently with accurate pressure gauges, an increase of more than 20 mbar per year may indicate fouling or other problems. The most common problems and their recommended corrections are: 1. Indication: Possible cause: Procedure: Possible cause: Procedure: Large volume of air in localized area Leakage in lateral...

Open the catalog to page 6

Specifications 7.4 Maintenance and Cleaning 7.4.1 Maintenance Check aeration continuously during regular operation for non-uniform bubble pattern and higher than expected headloss. Depending on the type of wastewater, treatment process, and operating conditions fouling of membranes may occur, thus reducing oxygen transfer. Remove deposits from membrane regularly, at least once a year. Sludge must not dry on the surface of the membrane, once hardened the sludge sticks to the membrane and will clog diffusers permanently. 7.4.2 Mechanical Cleaning Deposits on membranes can be removed just with...

Open the catalog to page 7

Check if air outlets of diffuser tube are pointing up/downwards. Adjust position if necessary, see chapter 6.3 for details. Use new gaskets! Push membrane over tube. Compare both non-perforated ends, and slide the longer zone first onto the plastic tube, it should cover the coloured zone of the tube. Both non-perforated strips along the membrane must face exactly up/downwards. Pull new clamps over the sleeve and adjust them at the proper position on both ends of the diffuser. Use spare diffusers from JUT to locate the optimum position of clamps. Use special pair of nippers (JUT # 12001) to...

Open the catalog to page 8All Jäger Umwelt-Technik GmbH & Co. KG catalogs and technical brochures

-

Waste Water Aeration

13 Pages

-

TD63 EPDMperformance C34

4 Pages

-

HD340 F053 F31

4 Pages

-

HD200 Silicone J24

4 Pages

-

HD270 F053 J27

4 Pages

-

Disk Diffuser

8 Pages

-

Waste Water Aeration

13 Pages