Catalog excerpts

Packed Plunger Metering Pumps 0.38-150 GPH Flow Rate 75-2,000 PSIG Pressure • A low-cost, uninterrupted, trouble-free service for the continuous, accurate metering of chemicals and solutions. • Available in simplex and duplex models, field convertible from simplex to duplex FEATURES & BENEFITS • Provides a simple and virtually maintenance-free approach to accurate chemical feed. • Stroke rate easily automated using variable-speed drive. • Capacity is manually adjustable, but only while pump is stopped, as a safety precaution and for tamper resistance. • Stroke length is adjustable for a turn-down ratio of 10:1. • Available with or without motor. • Oil bath gear lubrication eliminates the maintenance required by auxiliary oil systems. • Single ball check valve, standard on both suction and discharge side of the pump, provides accurate metering and fast response. Valve ball turns with fluid flow, constantly presenting a new face to the seat, and is therefore self-cleaning. • Because it is a true positive displacement pump, a safety relief valve on all closed loop systems is required to prevent possible overpressuring the discharge line. • Packing adjustment screwed gland nut ensures even take-up and fewer packing problems. • Integral lantern ring for packing lubricant may be used for internal purging when handling crystallized, corrosive or other hazardous liquids. • Pump arms can be reversed to reduce footprint. • Duplex pumps can have different size pistons. • Pistons are normally 180° out of phase, but can be synchronized so that two fluids are pumped simultaneously (i.e. resin and hardener in a fiberglass plant). • Accuracy of ± .5% at steady state. • All units come epoxy painted, completely assembled on a base plate and have been fully tested PUMP OPTIONS • Double ball check valves with or without spring-loaded balls. • Purge-port plugs, available in cylinder end, can be used to bleed air during and after start-up and to solvent-purge the liquid end. They also provide easy access to the cylinder without breaking pipe connections. • 440 hardened plunger for abrasive fluids. MOTOR OPTIONS • Pressure relief valves • Back pressure valves • Calibration columns • Pulsation dampeners • Pressure gauges 316 Stainless Steel Alloy 20

Open the catalog to page 1

JAECOPAK™ MODELS MAXIMUM CAPACITY (2) MODEL # PSIG KG/CM PSIG KG/CM2 Speed in strokes per minute Liquid End Material 2 - 316 Stainless Steel 3 - Alloy 20 Packing: N = Neoprene, T = PTFE, V = Viton Motor Horse Power 2 - 1/3 HP 3 - 1/2 HP 4 - 3/4 HP Y - less motor Options: Consult factory Determine type of Jaeco pump to use. Select appropriate model from capacity/pressure chart. Or, contact your Jaeco representative with the following information: fluid name, concentration and compatibility; fluid properties – viscosity, temperature, vapor pressure, particle matter size and percent; maximum...

Open the catalog to page 2All JAECO Fluid Systems catalogs and technical brochures

-

316SS Check Valves

1 Pages

-

Jaeco CutSheet HiFlo

2 Pages

-

Jaeco CutSheet AgriPak

2 Pages

-

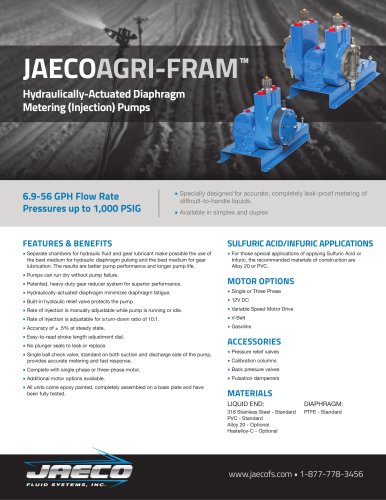

Jaeco CutSheet AgriFram

2 Pages

-

Jaeco CutSheet Fram

2 Pages