Catalog excerpts

Packed Plunger Metering Pumps 20-682 GPH Flow Rate 65-7,200 PSIG Pressure • Continuous, accurate metering at higher flow rates and/or pressures. • Available in simplex and duplex models FEATURES & BENEFITS • Provides a simple and virtually maintenance-free approach to accurate chemical feed. • Stroke rate easily automated using variable-speed drive. • Capacity is manually adjustable, but only while pump is idle, as a safety precaution and for tamper resistance. • Stroke length is 0 to 100% adjustable for a turn-down ratio of 10:1. • Available with motor or as bare pump. • Single ball check valve, standard on both suction and discharge side of the pump, provides accurate metering and fast response. Valve ball turns with fluid flow, constantly presenting a new face to the seat, and is therefore self-cleaning. • Because it is a true positive displacement pump, a safety relief valve on all closed loop systems is required to prevent posssible overpressuring the discharge line. • Integral lantern ring for packing lubricant may be used for internal purging when handling crystallized, corrosive or other hazardous liquids. • Packing adjustment screwed gland nut ensures even take-up and fewer packing problems. • Models 324, 332 and 340 have a clamped column, suction and discharge check valve assembly that can be easily cleaned, inspected or replaced without breaking pipe connections. • Accuracy of ± .5% at steady state. • All units come epoxy painted, completely assembled on a base plate and have been fully tested. PUMP OPTIONS • Double ball check valves with or without spring-loaded balls. • Purge-port plugs, available in cylinder end, can be used to bleed air during and after start-up and to solvent-purge the liquid end. They also provide easy access to the cylinder without breaking pipe connections. MOTOR OPTIONS • Pressure relief valves • Back pressure valves • Calibration columns • Pulsation dampeners • Pressure gauges 316 Stainless Steel Alloy 20 SEALS: Neopre

Open the catalog to page 1

JAECOHI-FLO™ MODELS MODEL #(1) MAXIMUM PRESSURE PSIG (3) 1. Jaeco model numbers consist of 10 digits. See explanation. 2. Flow rates are based on water at maximum rated pressure. 3. For steel construction, maximum temperature is 350°F. Speed in strokes per minute Liquid End Material 2 - 316 Stainless Steel 3 - Alloy 20 Packing: N = Neoprene, T = PTFE, V = Viton Options: Consult factory Determine type of Jaeco pump to use. Select appropriate model from capacity/pressure chart. Or, contact your Jaeco representative with the following information: fluid name, concentration and compatibility;...

Open the catalog to page 2All JAECO Fluid Systems catalogs and technical brochures

-

316SS Check Valves

1 Pages

-

Jaeco CutSheet AgriPak

2 Pages

-

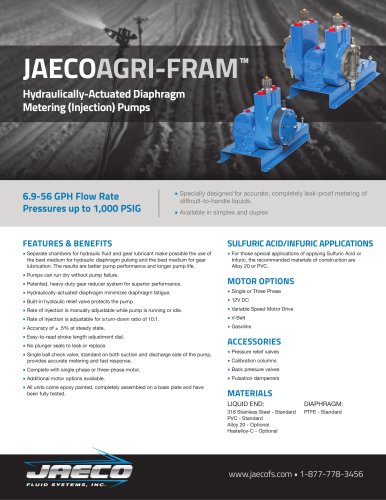

Jaeco CutSheet AgriFram

2 Pages

-

Jaeco CutSheet Fram

2 Pages

-

Jaeco CutSheet Pak rev2

2 Pages