Catalog excerpts

Models 31800-Series 31801-Series (Excludes: 31801-0115 & 31801-1305) INDUSTRIAL DIAPHRAGM PUMPS 4 GPM/15 LPM FEATURES • • • • • Self-Priming Can run dry without damage Flow to 4 GPM/15 LPM Thermal Overload Protected Motor Snap-in 1/2" Dia. Port Adapters Easy Installation Low Amp Draw Compact Size Quiet Running SPECIFICATIONS Pump Body: Elastomers: Glass Filled Polypropylene Diaphragm made of Santoprene* Valves made of Viton** Hardware: 316 Stainless Steel Pump Design: Four-Chamber Diaphragm Suction Lift: Self-Priming to 10 ft (3m) (wet) 5 ft. (1.5m) (dry) Ports: 1/2" (13mm) Hose Barb and 1/2" (13mm) Straight Pipe Thread Motor: Permanent Magnet with Thermal Overload Protection Shipping Weight: 5.5 lb (2.5 kg) approx. (12/24 V models) Duty Cycle: Continuous at 15 psi (1 bar) and 70°F (21°C) ambient temperature Temperature: Liquid temperature range is 45°F to 130°F (7°C to 54°C) Viscosity: 250 cP maximum Road Rollers Parts Washing APPLICATIONS This pump provides excellent service in the following applications. CONSTRUCTION – Water supply pump to the spray bars of road rollers and other compaction equipment, street sweepers, and truck mounted dust control systems. Superior equipment washdown results can be enjoyed with the 30801-Series pumps. AGRICULTURAL – Supply pump for herbicide and pesticide sprayers and sprayboom equipment. NOTE: Viton equipped models are not suitable for potable water applications. Construction Equipment Washdown Spray Equipment INDUSTRIAL – Fluid transfer applications for mild acids and bases. Chemical feed pump. Washing fluid supply pump in parts washing systems. Machine coolant pump. Concrete saw lubricant supply pump. Recirculating pump in filtering systems. Pressure Switch Settings Recommended Nominal psi (bar) AMP Draw Fuse/Breaker† Cut-In Cut-Out @ 10 psi Sizes † Not included with pump. * Viton is a registered trademark of DuPont Dow Elastomers L.L.C. ** Santoprene is a registered trademark of Monsanto.

Open the catalog to page 1

OPERATING INSTRUCTIONS 1. MOUNTING – JABSCO diaphragm pumps are self-priming and may be located in a dry location above or below the fluid supply. To vertically mount these units, it is best to do so with the motor on top. This will prevent fluid dripping on the motor in the event of a leak. PLACE PUMP ON A SOLID SURFACE AND SECURE WITH FOUR MOUNTING SCREWS BEING CAREFUL NOT TO FULLY COMPRESS THE RUBBER GROMMETS WHICH ACT AS SHOCK ABSORBERS. 2. PLUMBING – Port adaptors are supplied to fit 1/2" (13 mm) dia. ID hose or 1/2" (13mm) dia. straight pipe threads. Use Teflon* (PTFE) type tape when...

Open the catalog to page 2

EXPLODED VIEW PARTS LIST Model Bearing cover 9 not included in diaphragm Kit 3 . SERVICE INSTRUCTIONS Before servicing pump, turn off electrical power and open discharge valve to relieve pressure in pump. Neutralize any chemicals prior to disassembly. PUMP DISASSEMBLY 1. Remove power from pump. Push port clips back and disconnect plumbing from pump. 2. Remove the four (4) pumphead screws.. 3. Rotate pumphead until cam/bearing set screw is visible through drain notch. 4. Loosen cam/bearing set screw and slide pump off motor shaft. 5. Separate upper housing, lower housing, and check valve...

Open the catalog to page 3

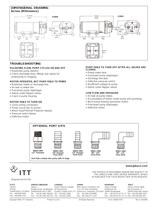

DIMENSIONAL DRAWING Inches (Millimeters) 8-15/16 (227) TROUBLESHOOTING PUMP FAILS TO TURN OFF AFTER ALL VALVES ARE CLOSED. • Empty water tank. • Punctured pump diaphragm. • Discharge line leak. • Defective pressure switch. • Insufficient voltage to pump. • Debris under flapper valves. PULSATING FLOW, PUMP CYCLES ON AND OFF • Restricted pump delivery • Check discharge lines, fittings and valves for undersizing or clogging. MOTOR OPERATES, BUT PUMP FAILS TO PRIME • Restricted intake or discharge line. • Air leak in intake line. • Punctured pump diaphragm. • Debris under flapper valves. •...

Open the catalog to page 4All Jabsco catalogs and technical brochures

-

Automotive

12 Pages

-

Flygt hydro turbines

8 Pages

-

Heavy Duty Coils

4 Pages

-

FanEx

4 Pages

-

AirEx

2 Pages

-

18940-0010

4 Pages

-

59520 series

2 Pages

-

Amazon Thrudeck

4 Pages

-

18660-0121

4 Pages

-

11810 series

4 Pages

-

12210 Series

2 Pages

-

36770 series

2 Pages

-

35760 series

4 Pages

-

35515-0010

2 Pages

-

34739 Series

4 Pages

-

Model 37202 Series

14 Pages

-

Model 34600 Series

14 Pages

-

Model 31705

4 Pages

-

Hy~Line and Ultima Lobe Pumps

52 Pages

-

GEAR PUPPY

2 Pages

-

Model 18680-1000

4 Pages

-

AMAZON MANUAL BILGE PUMPS

8 Pages

-

Impeller Replacement

16 Pages

-

Searchlights

12 Pages

-

Ventilation Blowers

8 Pages

-

Washdown Pumps

6 Pages

-

Water Pressure Systems

16 Pages

-

Toilet Systems

18 Pages

-

Bilge Pumping Systems

38 Pages

-

Flexible Impeller Pumps

40 Pages

-

General Purpose Pumps

4 Pages

-

Transfer Pumps

3 Pages

-

Specialty Products

12 Pages

-

Flexible Impeller Pumps part B

26 Pages

-

Flexible Impeller Pumps part A

15 Pages

-

Diaphragm & Drum Pumps

29 Pages

-

Centrifugal Pumps

37 Pages

Archived catalogs

-

Sliding Vane Pumps

10 Pages

-

Oscillating Pumps

2 Pages