Catalog excerpts

IVB Umwelttechnik GmbH Ihr Partner für Wertstoff-Behältersystem

Open the catalog to page 1

Content Introduction Company Data Construction & Prefabrication Galvanizing & Final Assembly Quality Management & Distribution Galvanized Skips ASM Jotha Refuse Collection Containers MGB Rear Side Loading Bin HSB Custom Made Containers

Open the catalog to page 2

Would you mind, we are the IVB Umwelttechnik GmbH We – the IVB Umwelttechnik GmbH – in Annaberg-Buchholz are your partner for hot dipped galvanized recycling bin systems and skips. Family run, midsize and independent, our name has been standing for quality products made in Germany since 1995. Our entire value chain, from development and production up to shipment, takes place at our home location in Annaberg-Buchholz in the Erzgebirge. State-of-the-art mechanical engineering in a production area of more than 7000 m² and our experienced staff of engineers and craftsmen offer the guarantee of...

Open the catalog to page 3

Land: State: City: Address: Germany Saxony Annaberg-Buchholz IVB Umwelttechnik GmbH Bleiche 4 09456 Annaberg-Buchholz District Geyersdorf

Open the catalog to page 4

Company Data Company designation Founding year Business purpose Manufacture of containers for waste management District court Chemnitz HRB 13577 Production area

Open the catalog to page 5

Construction & Prefabrication When manufacturing our containers, we always pay heed to only using the most high quality materials. As an example, for the body of our containers, we only use cold-rolled quality sheet metal DC 01, which is also used in the automobile industry and guarantees an increased strain to rupture. The material is therefore harder and crack-resistant. Our distributors also know that we apply the highest standards of quality, reliability, flexibility and costs. The leitmotif of our production is “Made in Germany”. Our machines that we use for die cutting, lasing and...

Open the catalog to page 6

Galvanizing & Final Assembly With the Annaberger Feuerverzinkung GmbH that was opened in November 2008 and fits right into the IVB Umwelttechnik GmbH premises, we’ve managed to enormously optimize the value-added process. We can therefore guarantee our customers galvanizing according to DIN ISO 1461 that is perfectly tailored to our containers as well as control of the entire production process. After leaving the Annaberger Feuerverzinkung GmbH the containers are then completely assembled, which means the component parts such as wheels, brakes and different lid systems are added.

Open the catalog to page 7

Quality Management & Distribution Optimized design for a high efficacy and long durability The optimized design and the robust model, targeted to the rough handling within waste management, our containers offer high efficiency and long durability to the users. In order to be able to guarantee this promise, all products are regularly tested and approved for quality, safety and in compliance with the relevant DIN standards. Of course, our Refuse Collection Containers comply the standards EN840-2 and -3/6, as well as our depot containers comply the requirements of noise protection of class 1. The...

Open the catalog to page 8

Our Products Through our own development department it is possible for us to implement your wishes and Requirements. Due to this constructive cooperation with you, we can ensure a continuous product improvement. The knowledge of your requirements led to many Patent-protected innovations that support you in your daily work. You also trust one of the leading manufacturers of container systems in Europe. We are happy to advise you! On the following pages you will find out more about: Front End Loader Rear End Loader Galvanizing Skips & Skips System Jotha Rear Side Loading Bin & Side-Load-Bin...

Open the catalog to page 9

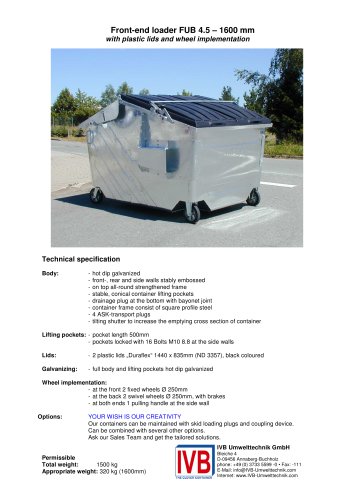

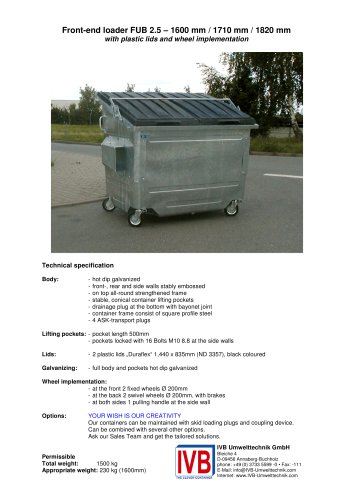

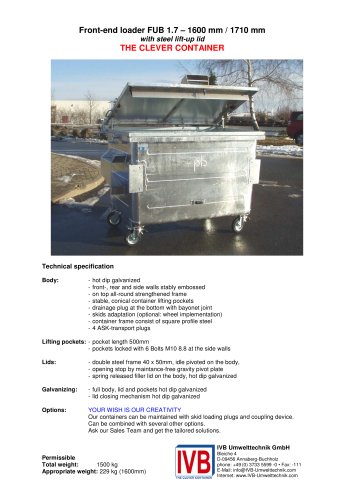

With plastic lid or spring-loaded steel lid - Container width 1600/1710/1820 mm • According to DIN EN 12574-1 • Body made of quality steel sheet • Embossed Front, back and side walls • Rounded container corners • Round reinforcing frame • Hull and frame completely welded • Hot-dip galvanized • Drainage plug at the bottom with bayonet joint • Lifting pockets, screwed TECHNICAL SPECIFICATIONS Container Model Throw in Admission Pocket height D width E width E1 1600, 4 plastic lid 1600, plastic lid 1710, plastic lid 1600, 4 plastic lid 1710, 4 plastic lid 1820, 4 plastic lid 1710, 4 plastic lid...

Open the catalog to page 10

With plastic lid or spring-loaded steel lid according to DIN EN 12574-1 • Body made of quality steel sheet • Embossed Front, back and side walls • Container bottom reinforced by profiles • Round reinforcing frame • Body and frame completely welded • Hot-dip galvanized • Drainage plug at the bottom with bayonet joint • 2 lifting pipes (lifting on 1 end) • Rear cover retention as standard TECHNICAL SPECIFICATIONS Container Model

Open the catalog to page 11

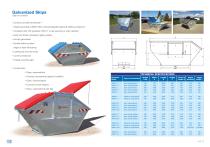

Galvanized Skips Open or covered • Conforms to DIN EN 307020-1 • Tested according to BGR 186-6 „Interchangeable tipping & settling containers“ • Compliant with VDI guideline 2700-17 „Load securing on road vehicles“ • Body and frame completely tightly welded • Hot-dip galvanized • Double-sided tunneled single or triple tilt bearing • Lashing bar and net hooks • Corners reinforced • Forged recording taps • Construction: + Open, asymmetrical + Covered, symmetrical (plastic & steellid) + Open, funnel-shaped + Covered, funnel-shaped + Open, asymmetrical with flap TECHNICAL SPECIFICATIONS...

Open the catalog to page 12

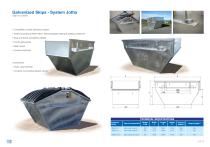

Galvanized Skips - System Jotha Open or covered • Compatible to Jotha admission system • Tested according to BGR 186-6 „Interchangeable tipping & settling containers“ • Body and frame completely welded • Hot-dip galvanized • Mesh hooks • Corners reinforced Construction: + Open, asymmetrical + Covered, symmetrical (plastic cover) TECHNICAL SPECIFICATIONS Container Model Jotha, open, asymm. Jotha, open, asymm. Jotha, plastic lid, symm.

Open the catalog to page 13

Depot Containers DCP & DCG 2,0 - 3,6 m³ • One and two chamber design according to DIN EN 13071 • Hook, double hook or double pull rod system • All components interchangeable • Fully welded, hot-dip galvanized container frame • Roof, floor flaps, front, rear and side walls made of industrial hot-dip galvanized steel sheet • Roof brace with drawbar connection • Edge protection at the container corners (powder coated in RAL color, on request) • Depot container paper - Paper insertion hoods • Depot container glass - Design in noise protection class 1 and 3 (powder coated in RAL color, - Floor...

Open the catalog to page 14All IVB Umwelttechnik GmbH catalogs and technical brochures

-

UB 3,0 plastic lids

2 Pages

-

UB 2,5 steel lids

2 Pages

-

FUB 7,5 1710 steel lid

2 Pages

-

FUB 2,5 1600 steel lid

2 Pages

-

DCG

2 Pages

-

DCP

2 Pages

-

UB 3,0 steel lids

2 Pages

-

UB 2,5 plastic lids

2 Pages

-

FUB 7,0 1600 steel lid

2 Pages

-

FUB 1,7 1710 steel lid

2 Pages

-

FUB 1,2 1600 metal lid

2 Pages