Catalog excerpts

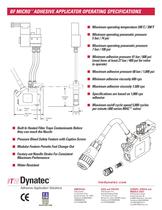

Shown withMicro Optima Module Actual Size ٢֠ ■■ > ■ Innovative Self-CleaningNozzle Virtually Eliminates Adhesive Stringing and Production DowntimeExtremely Long OperatingLife DesignAir Open / Air Closed DesignProvides Accurate and Uniform Adhesive Patterns and BeadsMicro Design AllowsInstallation in Compact Configurations > Adhesive Application Solutions size="-1">

Open the catalog to page 1

٢֠ Maximum operating temperature 200˚C / 390˚FMinimum operating pneumatic pressure5 bar / 74 psiMaximum operating pneumatic pressure7 bar / 100 psiMinimum adhesive pressure 41 bar / 600 psi(must have at least 27 bar / 400 psi for valve to operate)Maximum adhesive pressure 68 bar / 1,000 psi Minimum adhesive viscosity 600 cps Maximum adhesive viscosity 1,500 cps Specifications are based on 1,000 cpsadhesiveMaximum on/off cycle speed 5,000 cyclesper minute (400 series MAC ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ > valve) Built In Heated Filter Traps Contaminants Beforethey can reach the NozzlePressure Bleed...

Open the catalog to page 2All ITW Dynatec catalogs and technical brochures

-

APEX™

2 Pages

-

Dynamelt™ D

2 Pages

-

Dynamini™

2 Pages

-

Dynamelt™ SR

2 Pages

-

DM55 DynaDrum™

2 Pages

-

Ultra™ SCS

2 Pages

-

Velocity™

2 Pages

-

TPC-2

2 Pages

-

TPC-9

2 Pages

-

DY2008

2 Pages

-

EVC-1

2 Pages

-

Dynamelt? GC Series

2 Pages

-

ADS1

2 Pages

-

Adhesive Transfer Tower

2 Pages

-

PINCH BOTTOM APPLICATOR

1 Pages

-

Vector - Spray Applicator

2 Pages

-

Vector - Slot Applicator

2 Pages

-

Adhesive Feeder

2 Pages

-

Dynamelt S Product

1 Pages

-

Dynamelt M35

219 Pages

Archived catalogs

-

DY 2008 PATTERN CONTROLLER

2 Pages

-

APEX High Speed Slot Die

2 Pages