Catalog excerpts

BrazeTec 49/Cuplus for better saw blades h h h h The state of the art From the BrazeTec 49/Cu to BrazeTec 49/Cuplus Test results of the new sandwich alloy Results of practical trials LIGNA+ HANNOVER 2005 Martin Stroiczek, Brazing Center, BrazeTec GmbH Hanau LIGNA+ HANNOVER 2005, Hall 13, Stand A51

Open the catalog to page 1

BrazeTec 49/Cuplus for better saw blades Ideal cutting material PKD CBN Wisker reinforced ceramic Nitrite ceramics Oxide ceramic Heat resistance and hardness The state of the art Hard metals demonstrate high hardness, coupled with the best possible bending resistance. Coated cermets Coated hard Fine-particle metals hard metals Hard metals on WC basis PM-HSS coated LIGNA+ HANNOVER 2005, Hall 13, Stand A51

Open the catalog to page 2

BrazeTec 49/Cuplus for better saw blades The state of the art The different expansion coefficients between hard metal and steel create critical stresses in the hard metal. Heat expansion coefficients LIGNA+ HANNOVER 2005, Hall 13, Stand A51

Open the catalog to page 3

BrazeTec 49/Cuplus for better saw blades The state of the art The different expansion coefficients between hard metal and steel create critical stresses in the hard metal. Heat expansion coefficients Components unbrazed at room temperature Hard metal BrazeTec 4900 brazing film Steel component LIGNA+ HANNOVER 2005, Hall 13, Stand A51

Open the catalog to page 4

BrazeTec 49/Cuplus for better saw blades The state of the art The different expansion coefficients between hard metal and steel create critical stresses in the hard metal. Heat expansion coefficients Components at 690°C brazing temperature Hard metal BrazeTec 4900 brazing film Steel component LIGNA+ HANNOVER 2005, Hall 13, Stand A51

Open the catalog to page 5

BrazeTec 49/Cuplus for better saw blades The state of the art The different expansion coefficients between hard metal and steel create critical stresses in the hard metal. Heat expansion coefficients Components cooled to room temperature Hard metal BrazeTec 4900 brazing film Steel component LIGNA+ HANNOVER 2005, Hall 13, Stand A51

Open the catalog to page 6

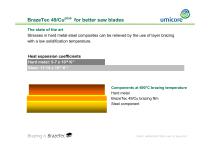

BrazeTec 49/Cuplus for better saw blades The state of the art Stresses in hard metal-steel composites can be relieved by the use of layer brazing with a low solidification temperature. Heat expansion coefficients Components unbrazed at room temperature Hard metal BrazeTec 49/CU brazing film Steel component LIGNA+ HANNOVER 2005, Hall 13, Stand A51

Open the catalog to page 7

BrazeTec 49/Cuplus for better saw blades The state of the art Stresses in hard metal-steel composites can be relieved by the use of layer brazing with a low solidification temperature. Heat expansion coefficients Components at 690°C brazing temperature Hard metal BrazeTec 49/Cu brazing film Steel component LIGNA+ HANNOVER 2005, Hall 13, Stand A51

Open the catalog to page 8

BrazeTec 49/Cuplus for better saw blades The state of the art Stresses in hard metal-steel composites can be relieved by the use of layer brazing with a low solidification temperature. Heat expansion coefficients Components cooled to room temperature Hard metal BrazeTec 49/Cu brazing film Steel component LIGNA+ HANNOVER 2005, Hall 13, Stand A51

Open the catalog to page 9

BrazeTec 49/Cuplus for better saw blades From the BrazeTec 49/Cu to BrazeTec 49/Cuplus Improvements in the quality of the brazing process, the design of the saw blades and the quality of the hard metals significantly reduce the failure rate. Hard metal Tooth seat Tooth shape Cutting edge Basic blade Thickness Material Hard metal seat Vibration damping LIGNA+ HANNOVER 2005, Hall 13, Stand A51

Open the catalog to page 10

BrazeTec 49/Cuplus for better saw blades From the BrazeTec 49/Cu to BrazeTec 49/Cuplus Improvements in the quality of the brazing process, the design of the saw blades and the quality of the hard metals significantly reduce the failure rate. Composition Coating Particle size LIGNA+ HANNOVER 2005, Hall 13, Stand A51

Open the catalog to page 11

BrazeTec 49/Cuplus for better saw blades From the BrazeTec 49/Cu to BrazeTec 49/Cuplus Improvements in the quality of the brazing process, the design of the saw blades and the quality of the hard metals significantly reduce the failure rate. Brazing material Flux agent type Intermediate Cu layer LIGNA+ HANNOVER 2005, Hall 13, Stand A51

Open the catalog to page 12

BrazeTec 49/Cuplus for better saw blades From the BrazeTec 49/Cu to BrazeTec 49/Cuplus Improvements in the quality of the brazing process, the design of the saw blades and the quality of the hard metals significantly reduce the failure rate. Brazing strip feed Flux dosing Tooth positioning Inductor shape Inductor position Brazing temperature Brazing time Contact pressure Brazing gap LIGNA+ HANNOVER 2005, Hall 13, Stand A51

Open the catalog to page 13

BrazeTec 49/Cuplus for better saw blades From the BrazeTec 49/Cu to BrazeTec 49/Cuplus Increased customer requirements include higher cutting speeds, new thin-cut tools and longer working life of the saw blade. Grinding wheel Particle size Grinding machine Grinding direction LIGNA+ HANNOVER 2005, Hall 13, Stand A51

Open the catalog to page 14

BrazeTec 49/Cuplus for better saw blades From the BrazeTec 49/Cu to BrazeTec 49/Cuplus Increased customer requirements include higher cutting speeds, new thin-cut tools and longer working life of the saw blade. Wood type Cutting speed Feed speed Environmental conditions Lubrication Cooling LIGNA+ HANNOVER 2005, Hall 13, Stand A51

Open the catalog to page 15

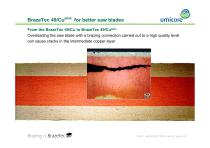

BrazeTec 49/Cuplus for better saw blades From the BrazeTec 49/Cu to BrazeTec 49/Cuplus Overloading the saw blade with a brazing connection carried out to a high quality level can cause cracks in the intermediate copper layer. LIGNA+ HANNOVER 2005, Hall 13, Stand A51

Open the catalog to page 16

BrazeTec 49/Cuplus for better saw blades From the BrazeTec 49/Cu to BrazeTec 49/Cuplus Overloading the saw blade with a brazing connection carried out to a high quality level can cause cracks in the intermediate copper layer. LIGNA+ HANNOVER 2005, Hall 13, Stand A51

Open the catalog to page 17

BrazeTec 49/Cuplus for better saw blades From the BrazeTec 49/Cu to BrazeTec 49/Cuplus Overloading the saw blade with a brazing connection carried out to a high quality level can cause cracks in the intermediate copper layer. LIGNA+ HANNOVER 2005, Hall 13, Stand A51

Open the catalog to page 18

BrazeTec 49/Cuplus for better saw blades Test results of the new layer brazing Shear trials on brazed test components confirm a significant increase in strength of the hard metal-steel composite. LIGNA+ HANNOVER 2005, Hall 13, Stand A51

Open the catalog to page 19All Italbras catalogs and technical brochures

-

Precious Metal Plating

16 Pages

-

UMICORE SEALING 691 EL

2 Pages

-

UMICORE ANTITARNISH 616 PLUS

2 Pages

-

PLATINODE® MMO ANODES

2 Pages

-

PLATINODE®

2 Pages

-

MIRALLOY®

2 Pages

-

RUTHUNA® 490 BLACK

2 Pages

-

RUTHUNA® 479 BLACK

2 Pages

-

RHODUNA® DIAMOND BRIGHT

2 Pages

-

PALLUNA® 458

2 Pages

-

AURUNA® 311

2 Pages

-

AURUNA® 215

2 Pages

-

ARGUNA® 621EF

2 Pages

Archived catalogs

-

6002

1 Pages

-

5600

1 Pages

-

5507

1 Pages

-

4576

1 Pages

-

4404

1 Pages

-

4076

1 Pages

-

3876

1 Pages

-

3476

1 Pages

-

3375

1 Pages

-

3076

1 Pages

-

3075

1 Pages

-

2576

1 Pages

-

2500

1 Pages

-

2009

1 Pages

-

1875

1 Pages

-

1204

1 Pages

-

503

1 Pages

-

Platinode

12 Pages

-

depots des metaux precieux

9 Pages

-

Brazing Pastes Catalogue

5 Pages

-

Brazing alloys product range

20 Pages