Catalog excerpts

PRODUCT OVERVIEW

Open the catalog to page 1

FOUNDING In 1990, ISO-TECH was founded with initially four employees. We quickly established ourselves as a polyethylene specialist in the market. EMPLOYEES We have continuously invested in the expansion of production width and vertical integration and we thereby provided new skilled jobs. 100 PERCENT EXPORT For many years, we have generated around half of our sales abroad. PLANTS With the opening of a second plant in 2010, we have expanded our range of products to include technical and high-performance plastics as well as new milling possibilities. MATERIALS With around 100 different...

Open the catalog to page 2

SHEETS & CUT-TO-SIZE Sheet materials and finished parts by ISO-TECH are made of different materials depending on requirements and intended use. We manufacture our sheet materials as well as our polyethylene finished parts on the basis of HIGH-MOLECULAR or ULTRA-HIGH-MOLECULAR ISO-LEN®. We produce POLYETHYLENE SHEETS of different sizes made of different materials in the sintering process in our own factory. In addition to our standardized sheet formats, you can also order sheet materials as a CUT-TO-SIZE WITH INDIVIDUAL DIMENSIONS. In addition to virgin and regenerated polyethylene, we also...

Open the catalog to page 3

PRODUCTION At ISO-TECH, you will receive PLASTIC MILLING AND TURNING PARTS made of different materials, which we produce for you according to your individual needs and specific application. Our machinery for the production of highly complex technical finished parts is one of the most modern in the industry. In addition, we use the possibilities of automation in the form of robot arms for feeding machines as well as in the form of closed automation centers. At the same time, we rely on conventional machines to complete our machinery, whenever this makes economic sense. In order to meet the...

Open the catalog to page 4

FINISHED PARTS Finished parts from ISO-TECH can be found today in almost ALL INDUSTRIAL AREAS. Depending on the industry and individual needs, we manufacture the most diverse thermoplastic finished parts for our customers – custom-fit and with the right degree of precision. Mechanical- and plant engineering • Track rollers and rope guide rollers • Abrasion protection strips & sliding strips • Wear strips and scrapers • Bushings • Rings & sleeves Packaging and conveyor technology • Conveyor stars • Guide and deflection rollers • Abrasion protection strips and sliding strips • Slip tables •...

Open the catalog to page 5

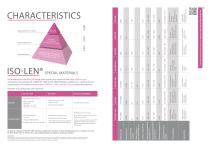

• Reinforced by microglass balls • uch better torsional strength M • uch better wear resistance with abraM sive media and high machine speeds • Basic material PE allows attachment to steel or base beams • Product-contacting carrier material TPE enables the storage and transport of painted or sensitive, finished-treated components All special materials of the ISO-LEN® family are obtained in the form of semi-finished products, i.e. sheets, cuts and twisted round rods, as well as, of course, a finished part according to drawing or pattern. Legal Notice All information contained in this product...

Open the catalog to page 6All ISO-TECH Kunststoff GmbH catalogs and technical brochures

-

ISO-TECH KUNSTSTOFF GmbH

9 Pages