Catalog excerpts

Wind energy needs Ipsen. Hard work wins

Open the catalog to page 1

Wind turbine manufacturers are exposed to a considerable risk: While gearbox damage is infrequent, the possibility cannot be excluded completely – and if it does occur, the manufacturer usually bears the risk for the first few years of operation. Gearboxes are being installed in more and more wind turbines. But the demands on them are extraordinarily high. Unlike most other industrial applications, the stresses are highly dynamic and are three-dimensional. In extreme weather, the shafts, gear wheels and bearings are put to the ultimate test. But turbine failures in offshore wind farms are...

Open the catalog to page 2

For decades, large gearboxes were manufactured almost exclusively using pit furnaces. But there is something better – both from an efficiency standpoint and in terms of ensuring the quality of the heat treatment results. The pit furnaces have been known for thousands of years. Until recently, they have been considered the only solution for the heat treatment of particularly large workpieces. Today, there are alternatives. So is the pit furnace still the optimal techology? Ipsen has researched the cost effectiveness of various heat treatment plants. We compared the costs of manufacturing...

Open the catalog to page 3

Ipsen is the only company offering one-stop shopping for all heat treatment components. From simple furnaces to complex systems – all incorporating the latest technology. The latest success from Ipsen’s Research & Development center: HybridCarb – a revolutionary gascarburising process. HybridCarb is an innovative gassing technique: Instead of being burned off, the process gas is fed back into the heating chamber in a recycling process. This reduces both CO2 emissions and process gas costs by up to 90 %. Other Ipsen technologies also facilitate the efficient heat treating of gearboxes:...

Open the catalog to page 4

Ipsen – we deliver performance. Ipsen stands for cutting edge heat treatment technology and systems. Few other enterprises in the world have had such a decisive impact on the development of heat treatment. For more than 60 years Ipsen has been providing innovative technologies and methods with which to give new properties to steel. Ipsen’s products combine the highest performance with outstanding reliability, which perhaps explains why our furnaces and heat treatment equipment enjoy an excellent reputation all over the world. The company has production sites in Europe, America and Asia....

Open the catalog to page 5All Ipsen International GmbH catalogs and technical brochures

-

IP-704 Fluid

2 Pages

-

Ipsen Plant Technology

7 Pages

-

Ipsen HydroNit Sensor

2 Pages

-

Ipsen Brazing

2 Pages

-

Ipsen Titan

9 Pages

-

Ipsen HybridCarb

3 Pages

-

Ipsen AutoMag® 4.0

3 Pages

Archived catalogs

-

Atmosphere Technology

5 Pages

-

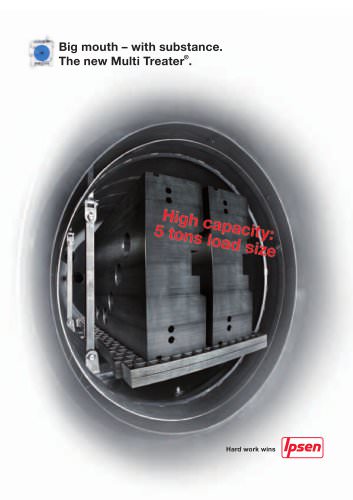

Ipsen Multi Treater

5 Pages

-

Carb-o-Prof® 4.0

3 Pages

-

Ipsen SolNit

3 Pages

-

Ipsen Turbo²Treater

6 Pages

-

Ipsen Vacuum Technology

6 Pages

-

Ipsen SuperQuench

3 Pages