Catalog excerpts

Hard work wins A new dimension in efficiency. The new Turboh2 Treater.

Open the catalog to page 1

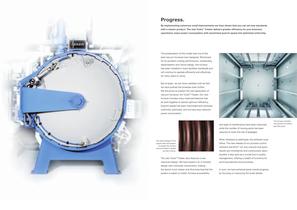

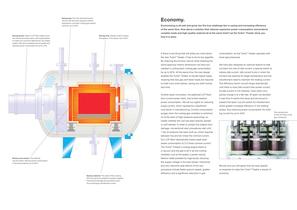

The ribbed design of the copper heat exchangers increases the surface area and helps to speed up load cooling. Progress. By implementing numerous small improvements we have shown that you can set new standards with a classic product. The new Turboh2 Treater delivers greater efficiency for your business operations: lower power consumption with maximised quench speed and optimised uniformity. The furnace chamber with Ipsen’s innovative gas flow grids. The predecessor of this model was one of the best vacuum furnaces ever designed. Renowned for its excellent cooling performance, outstanding...

Open the catalog to page 2

If there is one thing that will strike you most about the new Turboh2 Treater, it has to be its low appetite. By reducing the furnace volume while retaining the same spacious interior dimensions we have succeeded in cutting back cooling gas consumption by up to 20%. At the same time, the new design enables the Turbo h2 Treater to handle higher loads, meaning that less gas and fewer loads are required to treat more work pieces, saving you both money and time. Another Ipsen innovation, the patented LCP Start (low current power start), has further slashed power consumption. We set our sights...

Open the catalog to page 3

Certain types of steel require high quench speeds to harden and these depend to a great extent on how fast the cooling gas is let into the furnace. Briefed to enhance cooling performance, our design team tackled the challenge from two angles: by improving the top speed and by letting the gas in faster. Top speed was boosted by maximising the cooling gas pressure, which is now up to 12 bar. Flow speed has been increased by the introduction of our innovative LCP Start, which not only lowers power consumption, but also increases cooling intensity when the cooling cycle starts. Once the furnace...

Open the catalog to page 4

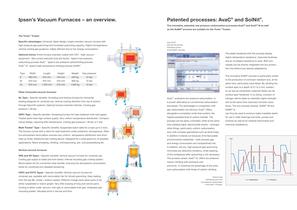

AvaC®, acetylene low pressure carburisation, is a proven alternative to conventional carburisation processes. The advantages in comparison with gas carburisation are obvious: AvaC® offers, alongside a completely oxide-free surface, the highest possible level of carbon transfer. The process can be easily controlled, while at the same time yielding highly reproducible results – amongst other things, particularly uniform carburisation, even with complex geometries such as blind holes. In addition it stands out because of its favourable environmental credentials – both process gas and energy...

Open the catalog to page 5

Hard work wins For over 60 years Ipsen has been finding new ways of producing steel of ever improving quality using the company’s innovative, proprietary technologies, such as the AvaC® process (low-pressure carburising), the SolNit® process (solution nitriding) and the recently developed HybridCarb process (gas carburising with recycling). Ipsen’s offerings combine the highest performance with outstanding reliability, which perhaps explains why our furnaces and heat treatment equipment enjoy an excellent reputation all over the world. Our customers work in automotive, aviation and...

Open the catalog to page 6All Ipsen International GmbH catalogs and technical brochures

-

IP-704 Fluid

2 Pages

-

Ipsen Plant Technology

7 Pages

-

Ipsen HydroNit Sensor

2 Pages

-

Ipsen Brazing

2 Pages

-

Ipsen Titan

9 Pages

-

Ipsen HybridCarb

3 Pages

-

Ipsen AutoMag® 4.0

3 Pages

Archived catalogs

-

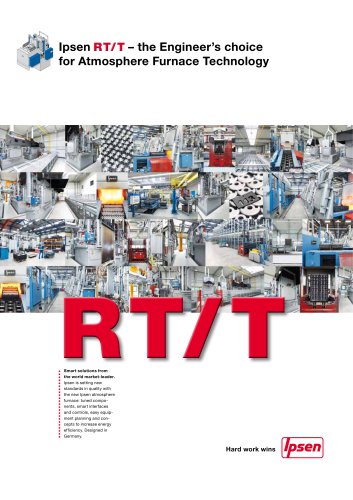

Atmosphere Technology

5 Pages

-

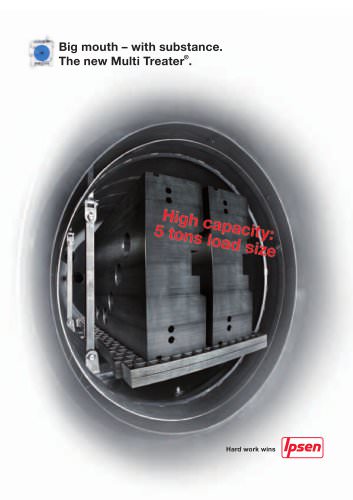

Ipsen Multi Treater

5 Pages

-

Carb-o-Prof® 4.0

3 Pages

-

Ipsen SolNit

3 Pages

-

Wind Energy

5 Pages

-

Ipsen Vacuum Technology

6 Pages

-

Ipsen SuperQuench

3 Pages