Catalog excerpts

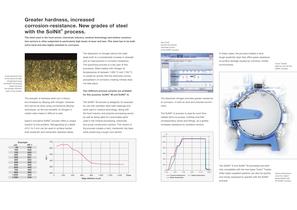

The SolNit® process. For steels that break new quality barriers. Hard work wins

Open the catalog to page 1

The dissolved nitrogen provides greater resistance to corrosion, in both an acid and chloride environment. The SolNit®-A process is used for such flowrelated items as pumps, turbines and their corresponding valves and fittings, as it greatly increases resistance to cavitation erosion. In these cases, the process creates a hard, tough austenitic layer that offers great resistance to surface damage caused by corrosive, hostile environments. The SolNit®-A and SolNit®-M processes are both fully compatible with the new Ipsen Turboh2 Treater. Older Ipsen-supplied systems can also be quickly and...

Open the catalog to page 2

If you require further information or would like to know more about our company and the products we make, please contact us. We look forward to hearing from you! Ipsen International GmbH Flutstraße 78 47533 Kleve Germany Telephone +49 2821 804-0 info@ipsen.de · www.ipsen.de Hard work wins For over 60 years Ipsen has been finding new ways of producing steel of ever improving quality using the company’s innovative, proprietary technologies, such as the AvaC® process (low-pressure carburising), the SolNit® process (solution nitriding) and the recently developed HybridCarb process (gas...

Open the catalog to page 3All Ipsen International GmbH catalogs and technical brochures

-

IP-704 Fluid

2 Pages

-

Ipsen Plant Technology

7 Pages

-

Ipsen HydroNit Sensor

2 Pages

-

Ipsen Brazing

2 Pages

-

Ipsen Titan

9 Pages

-

Ipsen HybridCarb

3 Pages

-

Ipsen AutoMag® 4.0

3 Pages

Archived catalogs

-

Atmosphere Technology

5 Pages

-

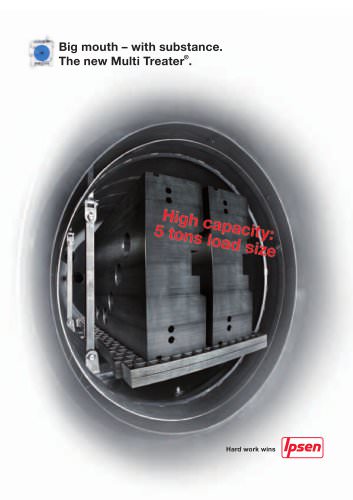

Ipsen Multi Treater

5 Pages

-

Carb-o-Prof® 4.0

3 Pages

-

Ipsen Turbo²Treater

6 Pages

-

Wind Energy

5 Pages

-

Ipsen Vacuum Technology

6 Pages

-

Ipsen SuperQuench

3 Pages